Page 12

8.

Fill the bearing assembly to the lower level of the

overflow vent.

9.

Add 5 or 6 drops of oil to the front and rear of

the motor. Use 20W non-detergent oil.

2F-10. Storage Tank Installation

1.

Be sure the floor is structurally capable of

supporting the tank when it is filled with water,

and is waterproof.

2.

Place the tank so that manholes, inspection

covers, nameplates and drain valves are

accessible.

3.

Be sure the tank is suitable for the water in the

system. Some water is corrosive and requires a

protected tank. Most tanks are available with

glass, plastic, or galvanized linings.

4.

If the tank is glass-lined, it should be equipped

with a suitable magnesium anode. It is a good

practice to replace the anode when it is

approximately 50 percent used. The factory

warranty on a glass-lined tank may be void if a

satisfactory anode is not in place at the time of a

failure or if it is consumed by cathodic action.

5.

The tank must be lined if a water softener is

installed in the system.

6.

Make sure the tank connections in the heater-

tank circulating loop are the proper size (see

Section 2F-5). If tappings are smaller than the

recommended pipe size, a larger pump may be

required. Consult the factory if in doubt.

7.

Install a pipe in the tank drain fitting that goes to

a floor sink, and install a drain valve. If a floor

sink is not available, install a hose bib.

8.

Hot water tanks in an existing installation are

likely to have silt deposits on the bottom.

Therefore, it is important to extend the pump

suction pipe in the tank to a position near the top.

Pipe the return from the heater to the bottom of

the tank.

2F-11. Thermal Circulation of Hot Water

in Cold Water Supply Lines

Under certain circumstances, thermal circulation

will occur in the cold water pipe supplying the water

to the heating system. This happens in a multi-story

building when the cold water pipe rises from its

connection to the system. To correct the problem, a

check valve in the cold water line supplying the heater

will prevent thermal circulation, and a small expansion

tank will permit heated water to expand without

popping off the relief valve.

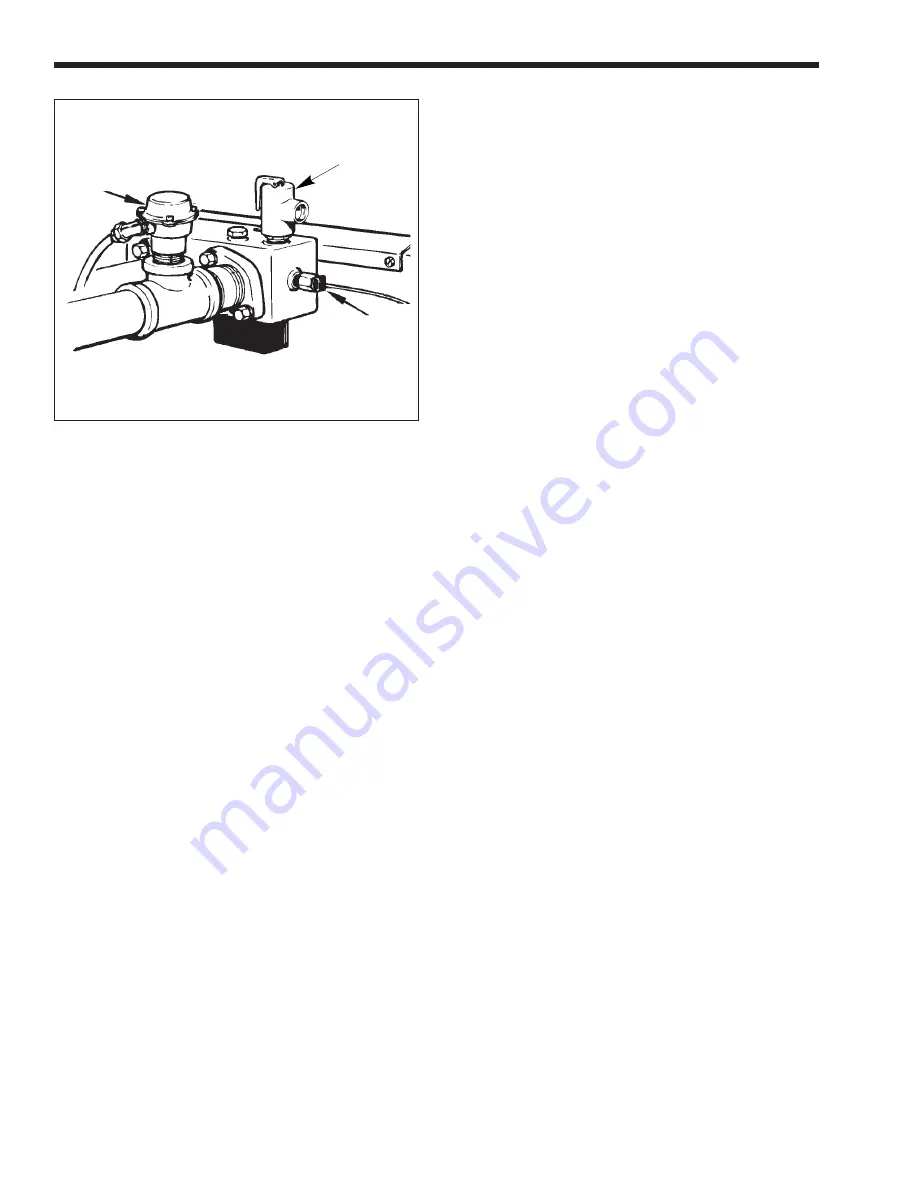

Flow

Switch

High-Limit

Dry Well

Pressure

Relief Valve

is turned back on. To eliminate the airlock, open the

pressure relief valve (see Figure 22) and allow the air

to bleed out until water starts to flow. As soon as full

circulation is restored, the trapped air will be released

through the hot water faucets.

2F-9. Pump Installation (Model VW)

1.

Install a properly sized pump to provide water

circulation between the heater and the storage

tank.

2.

Size the pump to avoid an excessive temperature

rise (see Table 4), and to provide the correct flow

for prevailing water hardness conditions.

3.

Install the pump in a cool location. The life of the

pump can be shortened by exposure to excessive

heat. If the pump is equipped with a thermal

protection device, excessive heat may trip the

thermal switch. This could cause the pump to

shut down intermittently, resulting in rapid

scaling of the heat exchanger.

4.

If designed for floor mounting, install pump

securely on concrete block or pad at least

6 inches (152 mm) above floor level. This will

prevent flooding of the motor when the floor is

washed.

5.

Do not suspend floor mounted pumps from

piping.

6.

Plumb piping to avoid putting strain on the pump

casing.

7.

Check the oil level in the pump before starting

the heater. Oil the pump every three months. Oil

pumps located in excessively hot or dusty

locations once a month. Self-lubricating pumps

do not require oiling.

Figure 22. Pressure relief valve.