NARVON

3

INSTALLATION

UNPACKING

POSITIONING

ELECTRICAL CONNECTION

1. Remove cardboard and plastic covering.

2. Make sure that the machine has not been damaged.

3.

Remove the plastic film from all the stainless steel panels.

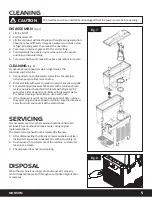

4. Before operating, remove the green plastic plug(s) from the tap(s). (Fig. 1)

1. Place the machine on a sturdy horizontal surface.

2. For improved ventilation, maintain a distance of 6

in. between the unit and walls or other obstacles.

Increase the distance if the obstacles are a heating

source. (Fig. 2)

3. Leave 60 in. of free space in front of the machine

to allow for easy use and maintenance. (Fig. 2)

4. Leave 10 in. of free space above the machine to

allow for removal of lids. (Fig. 2)

5. When the machine is in place, adjust the rubber

legs to level.

1. Make sure that the machine is properly connected

to an efficient grounding system, in compliance with

current safety standards;

2. Make sure that the voltage is in accordance with

what is indicated on the “serial number” tag applied

on the chassis.

3.

The current available is sufficient for the maximum

required by the machine;

4. If needed, use only approved multiple outlets, in

compliance with current safety standards

5. If in doubt, consult only specialized technicians.

6. By law, the machine must always be grounded.

If in doubt, consult a specialized electrical technician.

Before inserting the plug into the electrical outlet,

carefully read the following precautions:

In order to prevent the oil contained in the air-tight compressor from flowing into the cooling circuit, it is necessary to

always carry, store, and handle the machine in a vertical position, following the instructions found on the packaging.

If the machine was accidentally or purposely placed in a non-vertical position during transport, before operating

the machine it should be kept in a straight position for approximately 30 minutes to allow the oil to flow back

into the compressor.

6”

6”

6”

60”

Fig. 2

Fig. 1

Dispose of packaging materials correctly.

Do not leave within reach of children.

CAUTION

Summary of Contents for 378D2B26

Page 2: ...NARVON...