8

NO.

CODE

DESCRIPTION

3

226

Stainless Steel Tap with O-R

6

232

Pump Body compl

7

64,01

Thermostat (Liquid.1127)

11

317

Pump Motor 220V

11

318

Pump Motor 110V

12

154

Or for pump

13

56

Black Switch

14

57

Red Switch

47

85

Compressor 24lt.220V

47

86

Compressor 24lt.110V

47

820

Compressor 30lt.220V

47

821

Compressor 30lt.110V

47

67

Compressor 36/40lt.220V

47

81

Compressor 36/40lt.110V

48

404

Fan Motor Comp. 220

48

405

Fan Motor Comp. 110

48

72,01

Fan motor 10W 220 (h84)

48

71,01

Fan motor 10W 110 (h84)

54

150

Rubber Leg

58

775

OR for Stainless Steel Tap

63

234.01 Corner Plug New

65

626

Pump Tube T

66

667

Drip Tray

70

642

Bowl Gasket

71

724

Glasse Tray Compl

74

644

Bowl

77

668

Double Lid

79

663

Evaporator Cover

80

819

S/S Nut for Evaporator Cover

83

764

Single Lid

86

696

S/S Push Level

89

659.01

Shaft for Push Lever 1-2

89

659.02

Shaft for Push Lever 3-4

90

830,01 Spring for Tap

91

852

Metal Ring

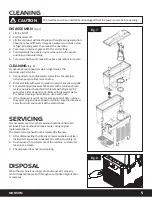

PARTS DIAGRAM

NARVON

Summary of Contents for 378D2B26

Page 2: ...NARVON...