8

W415-0153 / A / 10.29.01

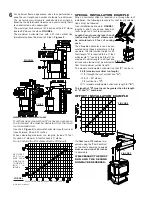

VERTICAL INSTALLATION:

This application occurs when

venting through a roof.

FIGURE 3.

Installation kits for vari-

ous roof pitches are

available from your Na-

poleon dealer. See Ac-

cessories to order the

specific kit required.

1.

Determine the air terminal location and move the stove

into position. Cut and frame 9 inch openings in the ceiling

and the roof to provide the minimum 1 inch clearance be-

tween the stove pipe and any combustible material. Try to

center the exhaust

pipe location midway

between two joist to

prevent having to cut

them. Use a plumb

bob to line up the

center of the open-

ings.

DO NOT FILL THIS SPACE WITH ANY TYPE OF MATERIAL.

A vent pipe shield will prevent any materials such as insu-

lation, from filling up the 1" air space around the pipe.

FIGURE 15.

Nail headers between the joist for extra sup-

port.

2.

Apply a bead of caulking (not supplied) to the frame-

work or to the Wolf Steel vent pipe shield plate or equiva-

lent (in the case of a finished ceiling), and secure over the

opening in the ceiling.

FIGURE 14.

A firestop must be placed

on the bottom of each framed opening in a roof or ceiling

that the venting system passes through.

FIGURE 13.

Apply

a bead of caulking all around and place a firestop spacer

over the vent shield to restrict cold air from being drawn

into the room or around the stove. Ensure that both spacer

and shield maintain the required clearance to

combustibles. Once the vent pipe is installed in its final

position, apply sealant between the pipe and the firestop

spacer.

3.

In the attic, after the pipe

has been installed, slide the

vent pipe collar down to cover

up the open end of the shield

and tighten. This will prevent any

materials, such as insulation,

from filling up the 1" air space

around the pipe.

FIGURE 15

VENT PIPE

SHIELD

VENT

PIPE

COLLAR

FIGURE 14

FIGURE 13

For safe and proper operation of the stove, follow

the venting instructions exactly.

HORIZONTAL INSTALLATION:

This application occurs

when venting through an

exterior wall.

FIGURES

4, 5, & 11.

Having deter-

mined the air terminal lo-

cation, cut and frame a hole

in an exterior wall with a

minimum square or round

opening of 9".

(As an alter-

native to framing, a vent

pipe shield may be in-

stalled, ensuring a 1" clear-

ance to combustibles.

See Figure 12

.)

For optimum performance, the stove pipe should rise

¼" per foot of run.

1.

Mark and cut the vent pipe shield to the determined

depth of the combustible wall. Apply a bead of caulking (not

supplied) to the framework or to the shield plate (in the

case of a finished wall) and secure the shield through the

opening to the interior wall.

The final location of the vent

pipe shield should maintain the required clearance to

the 7" vent pipe. Do not fill this cavity with any type of

material.

Apply a bead of caulking all around and place a

firestop spacer over the vent shield to restrict cold air from

being drawn into the room or around the stove. Ensure that

both spacer and shield maintain the required clearance to

combustibles. Once the vent pipe is installed in its final

position, apply sealant between the pipe and the firestop

spacer.

FIGURE 12

OR

WALL AND CEILING PROTECTION

FIGURE 11

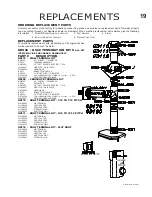

Summary of Contents for Haliburton GDS28N

Page 24: ...24 W415 0153 A 10 29 01 NOTES...