16

W415-0153 / A / 10.29.01

LIGHTING INSTRUCTIONS

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

The gas valve has an interlock device which will not allow the pilot burner to be lit until the thermo-

couple has cooled. Allow approximately 60 seconds for the thermocouple to cool.

When lighting and relighting, the gas knob cannot be turner from PILOT to OFF unless the knob is depressed.

1.

STOP!

Read the safety information on the operating

label.

2.

Turn off all electric power to the fireplace.

3.

Turn the gas knob clockwise

to off.

4.

Wait five (5) minutes to clear out any gas. If you smell

gas including near the floor,

STOP!

Follow "B" on the op-

erating label. If you don't smell gas go to the next step.

5.

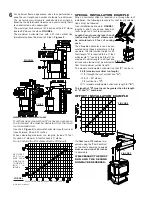

Find pilot located in front of the back log.

6.

Turn gas knob counter-clockwise

to pilot.

7.

Depress and hold the gas knob while lighting the pilot

with the push button igniter. Keep knob fully depressed

for one minute, then release. If the pilot does not con-

tinue to burn, repeat steps 3 through 6.

8.

With the pilot lit, turn the gas knob counter-clockwise

to on.

9.

If equipped with a remote ON-OFF switch, main burner

may not come on when you turn the valve to ON. The

remote switch must be in the ON position to ignite the

burner.

10.

Turn on all electric power to the fireplace.

PILOT

THERMOPILE

THERMO-

COUPLE

BURNER

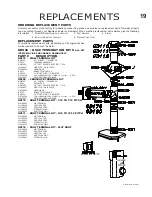

1.

Turn off all electric power to the fireplace if service is to

be performed.

2.

Push in gas control knob slightly and turn clock-

wise

to off. Do not force.

MAINTENANCE INSTRUCTIONS

Turn off the gas and unplug electrical

power before servicing the stove!

CAUTION: Label all wires prior to disconnection when serv-

icing controls. Wiring errors can cause improper and dan-

gerous operation. Verify proper operation after servicing.

This stove and its venting system should be inspected

before use and at least annually by a qualified service per-

son. The fireplace area must be kept clear and free of com-

bustible materials, gasoline or other flammable vapours

and liquids. The flow of combustion and ventilation air must

not be obstructed.

1

. In order to properly clean the burner and pilot assem-

bly, remove the logs exposing both assemblies.

2

. Keep the control compartment, logs, burner, air shut-

ter opening and the area surrounding the logs clean by

vacuuming or brushing, at least once a year.

3

. Check to see that all burner ports are burning. Clean

out any of the ports which may not be burning or are not

burning properly.

4

. Check to see that the pilot flames are large enough to

engulf the thermocouple and the thermopile on one leg

and reaches toward the burner on the other leg.

5

. Replace the cleaned logs.

6

. Check to see that the main burner ignites completely

on all openings when the gas knob for the burner is turned

on. A 5-10 second total light-up period is satisfactory. If

ignition takes longer, consult your Napoleon dealer/dis-

tributor.

7.

Check that the door gasketing is not broken or miss-

ing. Replace if necessary.

8.

Lift the door from its hinges to clean hinge pins and

lubricate using high-temp dry graphite if necessary. Re-

place.

NOTE:

Due to the high temperatures that the hinges ex-

perience, wet lubricants such as oil and WD40 will cause

the hinge to seize and are therefore not suitable.

TO TURN OFF GAS

P

I

PILO

T

N

O

L

O

T

H I

LO

FF

O

GAS KNOB AT OFF

Summary of Contents for Haliburton GDS28N

Page 24: ...24 W415 0153 A 10 29 01 NOTES...