5

nitrogen gas generator

GEN

2

i4.0

2. recommended tools

The following tools will be required to service the generator

• Terminal screw driver

•

3mm flat screwdriver

• Various metric allen keys/sockets

• Various metric spanners

•

Torque wrench (0-40nm)

• Food grade lubricating grease

3. maintenance guidelines

• Maintenance operations only to be conducted when the system has been shut down and

fully depressurised.

• All connections must be undone with care, paying particular attention to the areas that

become pressurised.

• Do not modify or adjust the control settings.

•

Only certified nano-purification solutions approved replacement parts to be used.

• Always check all connections for leakage and secure seating before operation.

•

Ensure all loose parts removed during maintenance are refitted correctly before operation.

4. shut down procedure before maintenance

If only Service A is to be carried out, only step 1 to 7 is required.

1. Isolate the buffer tank inlet and outlet.

2. Isolate the inlet air supply

3. Isolate the Nitrogen outlet

4. Allow unit to shutdown on low inlet pressure, unit shutdown will

take approximately 2 minutes

to complete a full shutdown

5. Press the Start / Stop button on the controller

6. Remove mains power from the generator.

7. Open the generators door to gain access to the control panel

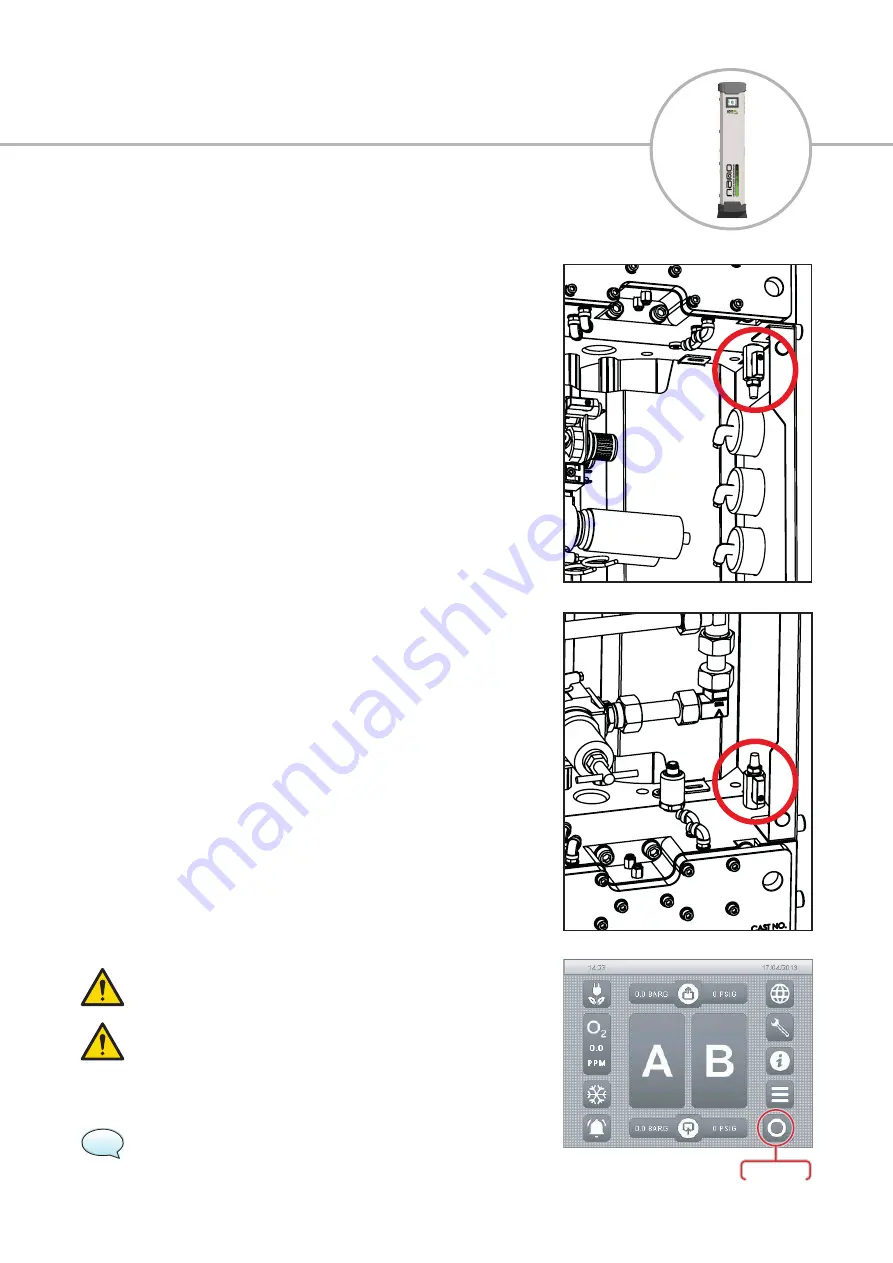

8. Open both service valves mounted on the inlet & outlet manifolds.

9.

Allow the unit to stand until no venting sound is heard from both

valves before carrying out any service work on the generator.

The configuration and orientation may vary per model

Before performing any maintenance or service operations on

this product, ensure the product is isolated from the compressed

air supply and fully depressurised. Also, ensure the product is

switched off and isolated from the mains power.

Characteristics of the CMS, pressure can build up to 2 Barg

after being shut-down

Service Valve Bottom

Service Valve Top

HOLD