11

Presentation

Installation inspection

I

Attention! :

Your engine must be installed by an authorised shipyard or a qualifi ed Nanni Industries representative in

accordance with the on board assembly instructions. However, you can check some important points on the installation

of the engine.

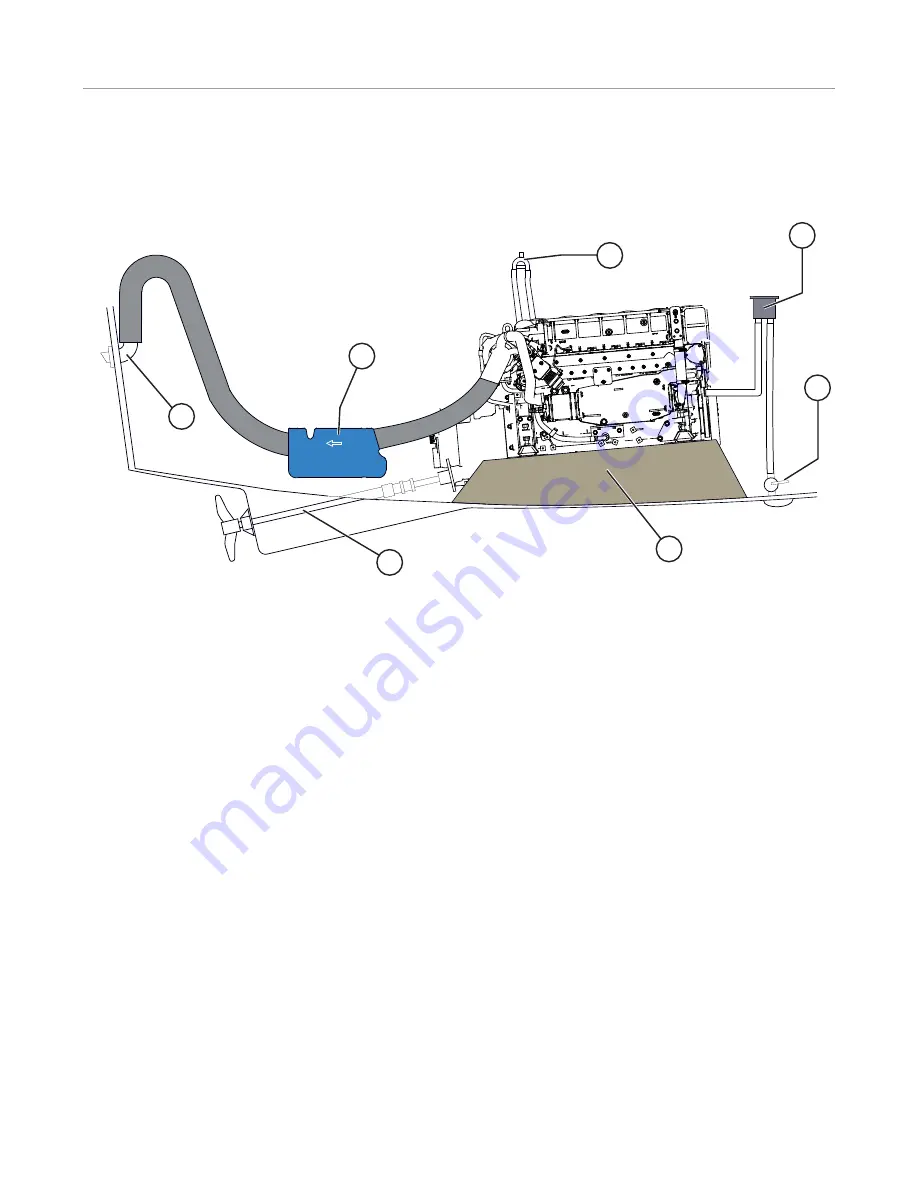

1. Engine frame

The engine frame must be solid and able to absorb all the

dynamic stress as well as the weight of the engine. It must

be connected to the hull by an area as large as possible.

The engine must not be at an angle of more than 15° when

the boat is stopped.

2. Propeller shaft

The choice of propulsion system must be made according

to the restrictions arising from the engine, the boat, and the

use of the boat.

3. Waterlock exhaust box

The waterlock must be positioned as close to the engine

and as low as possible.

4. Hull outlet

The hull outlet must be located 15cm below the water line.

The tube between the exhaust box and the hull outlet must

form a swan-neck shape to avoid any water getting into the

exhaust system through the hull outlet.

5. Anti-siphon valve

Mandatory on boats whose engine is below the waterline.

The anti-siphon valve must be installed at the end of the

seawater system before injection in the exhaust elbow and

must be positioned above the waterline, between 0.5 and

2 metres.

6. Seawater filter

This must always be positioned at least 15 cm above the

waterline.

7. Through-hull valve

On yachts and boats that do not go above 12 knots, the

water inlet must be turned towards the end of the boat.

On motor boats that go over 12 knots, the water inlet must

be turned forwards the end of the boat.

Engine room

The temperature inside the engine compartment must not

exceed 50°C with a maximum difference of 20°C with the

outside temperature.

Slow boats must have a ventilator fitted. Fresh air from the

front is circulated from front to back. The front air intake is

located low down at the front of the engine compartment

and the outlet high at the back for optimum air circulation.

Electrical installation

An incorrect or faulty electrical installation can cause

leakage currents that can affect the galvanic protection of

the engine and damage the engine subsequently.

The installer must ensure to take all necessary precautions

to protect the engine against corrosion.

4

3

5

6

2

1

7