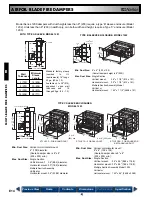

HOW TO ORDER:

Select model number and size, then select from each variable as applicable. Choose accessories as desired.

See previous page for description of variables and accessories.

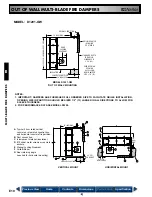

Notes: 1.

*

Standard sleeve is 16" (406) long (suitable for 4" (102) thick wall) x 20 ga. (1.0).

HOW TO SPECIFY OR TO ORDER

E20

VEE-GROOVE BLADE FIRE DAMPERS

MULTI-BLADE FIRE DAMPERS

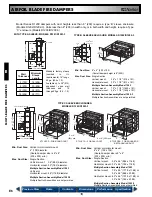

MODELS: D1250/D1251/D1252/D1253

MODEL

SIZE

(W X H)

MOUNTING

CLOSURE DEVICE

CLOSURE TEMP

.

SLEEVE LENGTH

*

SPECIFY

LENGTH

SLEEVE GAUGE

*

JAMB SEALS

(OPTIONAL)

BLADE SEALS

(OPTIONAL)

DAM

PER LOCA

TION

IN SLEEVE

TRANSITION TYPE

(MODEL

1253

ONL

Y)

D1250

ie: 36" x 24"

V

24

FL

165

20G

CR

L8

NONE NONE

300D

D1251

or

H

34

212

18G

CO

L0

JSM

BPV

SMP

D1252

18" dia.

16G

CSR

QS1

D1253

14G

QS2

10G

TDF1

TDF2

ACCESSORIES

E

MUL

TI-BLADE

FIRE

DAMPERS

E20

Revised September 23, 2004

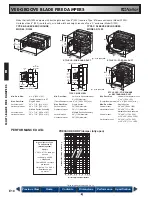

SUGGESTED SPECIFICATION:

Provide and install, as shown on plans and/or schedules, multi-blade Dynamic Fire Dampers, as manufactured by Nailor

Industries, meeting or exceeding the following criteria: Frame shall be constructed of 16 ga. (1.6) galvanized steel hat channel

with mitered corners reinforced with die-formed corner gussets for strength. Blades shall be of vee-groove design 16 ga. (1.6)

galvanized steel on 5 1/2" (140) centers and shall be parallel configuration. Blade axles shall be 1/2" (13) dia. plated steel,

double bolted at each end of blade to ensure positive locking connection. Hex or square friction-fit, or press-fit axles are not

acceptable. Bearings shall be self-lubricating oilite bronze type. Blade linkage shall be zero-maintenance, concealed in frame,

out of airstream.

Fire dampers shall meet the requirements of NFPA 90A and shall be manufactured, tested and labeled in accordance with UL

555 Safety Standard for Fire Dampers – Sixth Edition, June 1999, including Dynamic Closure Test. Dampers shall be classified

for dynamic closure against an airflow velocity of 2000 fpm (10.16 m/s) or 3000 fpm (15.24 m/s)

(specifier select one)

at 4"

w.g. (1 kPa) static pressure differential (across closed damper).

Each fire damper shall bear a UL 1 1/2 hour fire resistance rating label, in addition to label verifying the airflow and closure

pressure ratings as established by the Dynamic Closure Test. Each fire damper shall also be marked with the words "For use

in dynamic systems". Dampers marked "For use in static systems only" are not acceptable.

Each fire damper shall be complete with a

(specifier select one)

165°F (74°C)

or

212°F (100°C) UL Listed fusible link that

will cause the damper to close and lock in closed position by means of an over-center/knee lock linkage for assured closure.

Fire dampers shall each include a steel sleeve of appropriate length/gauge as field verified by contractor, and retaining angles,

supplied by damper manufacturer to ensure proper installation in accordance with damper manufacturer’s instructions. Each

damper shall be supplied with an internal manual quadrant(s) for setting and locking of blades in desired position. Contractor

shall provide and install an access door at each fire damper, of appropriate size to allow for inspection, testing and fusible link

replacement. Information submitted for approval shall include independent pressure drop data and confirmation of UL

qualifications in addition to manufacturer’s installation instructions. Each shipment of fire dampers shall include same

installation instructions. Standard of acceptance: Nailor Industries Model Series D1250.

MAX. VELOCITY/

PRESSURE RA

TING

Specification Text File

Previous View

Contents

Dimensions

Performance

Specification

Home