SUGGESTED SPECIFICATION:

MODEL: 1290F

Provide and install, as shown on plans and/or schedules True Round Fire Dampers, as manufactured by Nailor Industries,

meeting or exceeding the following criteria: Frame/integral sleeve shall be roll-formed from 20 ga. (1.0) galvanized steel,

beaded for structural strength and grooved to accept 20 ga. (1.0) galvanized steel retaining plate. Required sleeve length shall

be field verified by contractor. Each damper shall be complete with retaining plate and 20 ga. (1.0) galvanized steel damper

plate, supplied by the damper manufacturer to ensure proper fit and installation. Blade shall be of two 20 ga. (1.0) galvanized

steel pieces laminated together with an equivalent thickness of 14 ga. (2.0). Blades axles shall be 1/2" (13) dia. plated steel

double bolted to blade. Hex or square friction-fit or press-fit axles are not acceptable. Bearings shall be self lubricating oilite

bronze type.

Fire dampers shall meet the requirements of NFPA 80, 90A & 101, and shall be manufactured, tested and labeled in accordance

with UL 555 Safety Standard for Fire Dampers – Sixth Edition, June 1999, including Dynamic Closure Test. Dampers shall be

classified for dynamic closure against an airflow velocity of 2000 fpm (10.16 m/s) at 4" w.g. (1 kPa) static pressure differential

(across closed damper).

Each fire damper shall bear a UL 1 1/2 hour fire resistance rating label, in addition to label verifying the airflow and closure

pressure ratings as established by the Dynamic Closure Test. Each fire damper shall also be marked with the words "For use

in dynamic systems". Dampers marked "For use in static systems only" are not acceptable.

Each fire damper shall be complete with a

(specifier select one)

165°F (74°C)

or

212°F (100°C) UL listed fusible link that will

cause the damper to close and lock in closed position by means of an over-center/knee lock linkage for assured closure. Each

fire damper shall be supplied with a manual quadrant for setting and locking of blades in desired position. Contractor shall

provide and install an access door at each fire damper, of appropriate size to allow for inspection, testing and fusible link

replacement. Information submitted for approval shall include independent pressure drop data and confirmation of UL

qualifications in addition to manufacturer’s installation instructions. Each shipment of fire dampers shall include same

installation instructions. Standard of acceptance: Nailor Industries Model 1290F.

E22

TRUE ROUND FIRE DAMPERS

MODEL: 1290F

PERFORMANCE DATA:

3

0

0

1

0

0

2

0

0

3

0

0

0

4

0

0

0

6

0

0

0

7

0

0

0

.40

.02

.03

.04

.05

.06

.07

.08

.09

.20

.50

.60

.70

.30

1

5

0

0

5

0

0

7

0

0

4

0

0

2

0

0

0

1

0

0

0

.10

.25

.15

5

0

0

0

.015

.01

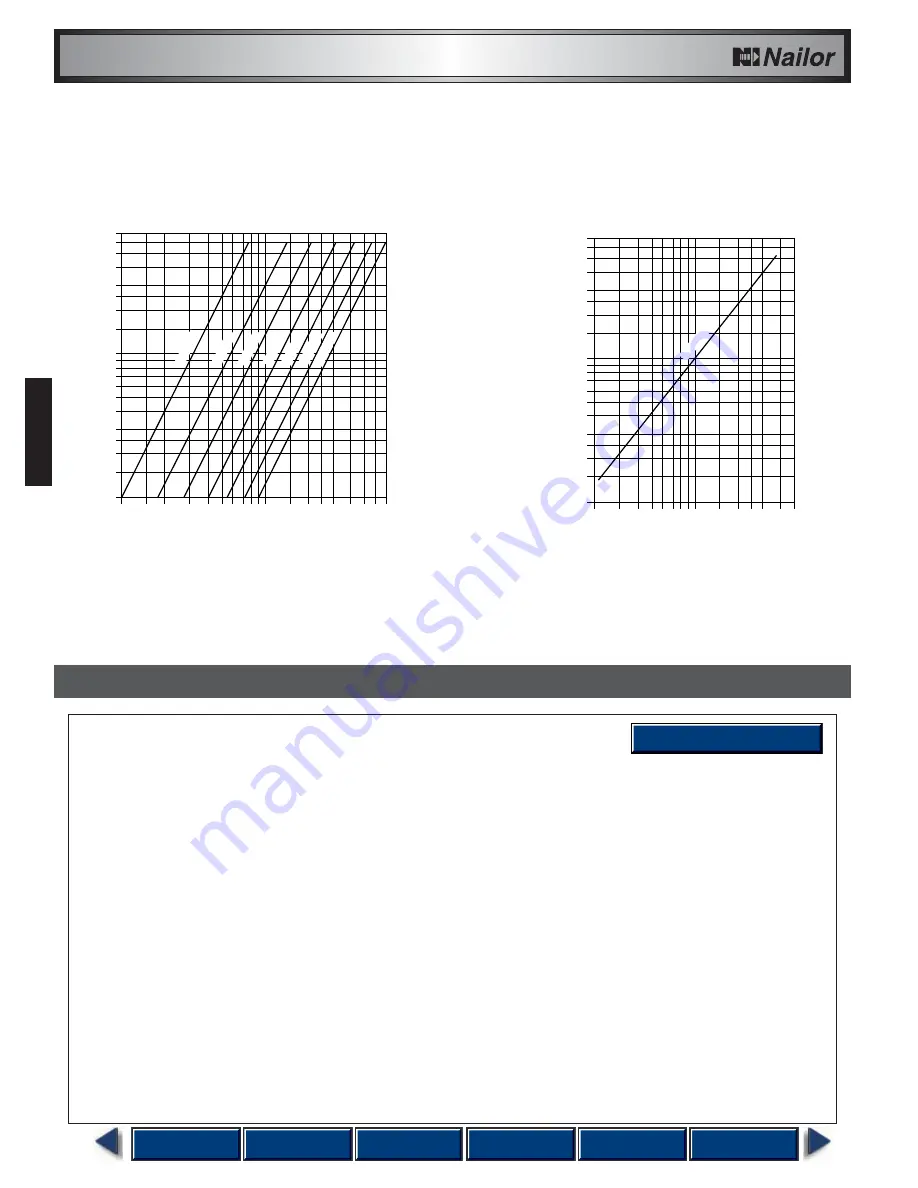

6" dia.

8" dia.

10"dia.

12"dia. 14"dia. 16"dia.18"dia.

Air Volume in CFM (through face area)

Static Pressure Dr

op in inc

hes w

.g.

.3

.2

3

4

4

.2

.3

.4

.5

.6

.7

.8

.9

2

5

6

7

3

1.5

.5

.7

.4

2

1

1.0

2.5

1.5

5

.15

.1

18" dia.

Air Leakage in CFM/ sq. ft. (through face area)

Static Pressure in inc

hes w

.g.

PRESSURE DROP (damper fully open)

AIR LEAKAGE (damper closed)

Tested per AMCA standard 500-D, Fig. 5.3.

Tested per AMCA standard 500-D, Fig. 5.5.

Imperial figures shown.

To convert to SI

(metric) system:

Multiply:

CFM x .4719 = liters

per second

inches w.g. x .2486

= kilopascals

fpm x .00508 = meters

per second

cfm per sq. ft. x 5.08 =

liters/second per

sq. meter.

E

MUL

TI-BLADE

FIRE

DAMPERS

E22

Revised September 7, 2004

HOW TO SPECIFY

Previous View

Contents

Dimensions

Performance

Specification

Home

Specification Text File