The oNeTRAK Manual

The oNeTRAK Manual

SPECIFICATIONS

3

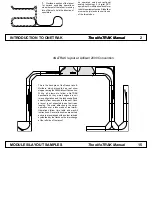

MODULES/LAYOUT SAMPLES

14

Standard NTRAK

layout

Junction module

"Gordonsville"

Offset module

module with

additional depth

180

°

return

loop module

corner

modules

oNeTRAK part of the Orlando '98 Convention layout

Arrows show direction of traffic

on extended Red Line Route

This was the first appearance of oNeTRAK in large

scale. The operating scheme extends the Red

Line Route through this part of the layout. The

Junction module (Gordonsville) permits both legs

of the Route to pass through. Trains enter

Gordonsville from the south on the right-hand

track. They pass through a turnout and head north

on single track. The engineer loops round

oNeTRAK's main and reenters Gordonsville from

the west. The train takes the right hand leg of the

wye and continues off the module back to the

south, this time on the second track. The straight

leg of the wye (at the front of the module) is never

used, so there is no reversing loop. An empty

boxcar is usually parked on this leg, awaiting

interchange and preventing operators from using

the track. Trains that remain on the oNeTRAK loop

during local operations can use the third leg of the

wye.

Most of these guidelines are based

on NTRAK standards.

1. HEIGHT OF TRACK Nominal

height is 40 inches. To make grades

longer than one module the module

interface on grades may need to be

changed from the 40 standard

height.

2. FRAME SIZES Frame lengths in

multiples of one foot. Twelve inches

is the minimum width. This width may

be increased up to an additional foot,

front or back for a total maximum

width of three feet.

3. MODULE INTERFACE Same as

NTRAK with one clamp and the stan-

dard 4.91" Atlas connector track sec-

tion. The frame on the module end

can be 1x3 or 1x4 lumber or plywood

equivalent.

4. TRACKS Code 80 track is stan-

dard. Code 55 is acceptable with

code 80 transitions at module inter-

face. Any Atlas, Peco or Micro Engi-

neering code 80 or code 55 turnouts

are acceptable. One track is re-

quired, additional through tracks are

permitted.

5. MINIMUM RADIUS is 18 inches

with appropriate easements. To pre-

vent binding the minimum length of

tangent between all reverse curves

must be 7 inches.

6. LOCATION OF TRACK On

straight modules the location of the

main has no impact on the loop of

modules and is not important, but

generally the track is set back 4 to 6

inches from the nominal front so that

the Fascia may be reasonably

aligned. Bump outs on the modules

are permitted, same as NTRAK.

Double or triple track should have

1.5-inch center spacing at the mod-

ule interface.

7. CORNERS Standard corners

can be 3 by 3 or 4 by 4 feet, etc. On

a standard corner the track should be

set back 6 inches from the nominal

front edge. This makes layout design

with inside corners easier. With track

set in 6" modules can be used as in-

side or outside corners and maintain

the one foot spacing increments.

8. CLOSING LOOP LAYOUTS

Due to the wide variety of frame sizes

and locations of tracks, some gaps

may develop in a loop layout. Most

large loops should be flexible enough

to close a gap by "scrunching" the

modules together. In some cases a

temporary bridge may be necessary.

This can be made by using a piece of

foam, some flex track and a bar

clamp to close the gap.

9. JUNCTIONS The smallest re-

commended junction is 3 by 5 feet.

10. GRADES 1.5 percent maxi-

mum across a dedicated set of mod-

ules. Grades on other modules can

be created with shims under legs of

modules. Grades suggest addition of

a helper district and helper engine

facility.

11. END TURNS are modules that

include a 180-degree curve in the

track. They should be a minimum of 2

by 4 feet to allow the 18-inch mini-

mum radius and easements. The dis-

tance between the ends of tracks on

an end turn must be three feet or

more in even foot increments.

12. TURNOUT SIZES All turnouts

should be number 6 or larger on the

mains, passing sidings and inter-

change tracks. Number 6 turnouts

are also encouraged in yards for bet-

ter operation.

13. ELECTRICAL The main line

has a red plug fastened the same

way as NTRAK. The white and 110

volt requirements are the same as

NTRAK. There are no special DCC

related wiring requirements. NTRAK

standards for wire gauge suffice.

14. SCENERY Any realistic scen-

ery is permitted. Round down hills on

the ends of modules so the view from

an adjacent flat module looks like

scenery. Colors for the fascia and

skirts should blend with the scenery

(generally shades of green or

brown). Do not use diorama dividers.

15. SKYLINE Skyboards or vertical

scenery flats are optional. In many

cases photography is easier if the

skyboard is removable.

16. PASSING SIDINGS To en-

hance operations most layouts

should include several passing sid-

ings. Clubs should try to include one

or more standard passing sidings in a

layout. A standard passing siding is a

set of two 1 by 4 feet modules with

turnouts at each end of the pair and

double track connecting the turnouts.

The resulting passing siding is about

seven feet long. Double or triple track

modules can be used to extend these

sidings.

17. OFFSET MODULES provide

track offsets in one-foot increments

for visual variety. Observe 18-inch

minimum radius and tangent track

between reverse curves standards.

18. OPERATIONS SCHEME Al-

though a stated purpose of

oNeTRAK is to provide a venue for

more prototypical operations, no op-

erational scheme is specified. Clubs

and individuals can tailor the operat-

ing scheme to their situation. To in-

crease potential for realistic opera-

tion, wireless DCC is recommended.

19. LAYOUT DESIGN oNeTRAK

modules have proven very flexible in

layout design both as part of an

NTRAK layout or when standing

alone. Note that NTRAK modules

can be used in a 1T layout.