The oNeTRAK Manual

The oNeTRAK Manual

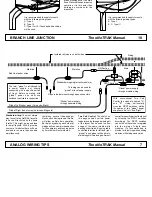

ANALOG WIRING TIPS

7

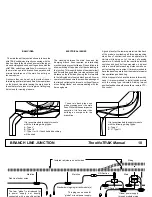

BRANCH LINE JUNCTION

10

A

A

B

C

B

C

It is recommended to supply turnouts

with the following wiring types:

A: Type V

B: Type III

C: Type II or III, if track behind backdrop

will be used

It is recommended to supply turnouts

with the following wiring types:

A: Type V

B, C: Type III

BASIC IDEA

The main idea of the junction shown is to have the

oNeTRAK subdivision directly connected with the

blue line. Usually the blue line has most of the indus-

tries and sidings and can be put to good use with the

oNeTRAK switching operations. A crossover over

the main lines permits branch line operation with

minimal interference of the main line activity on

those modules.

A scheme then can be set up to provide true car

forwarding and time table and train order operations

on the branch line while leaving the main lines to

those that prefer a less strict regime of letting long

trains loop for viewing pleasure.

ELECTRICAL ISSUES

The crossing between the main lines and the

diverging branch lines requires an interlocking

mechanism to prevent collisions. One solution is to

allow switching off a portion of all tracks leading to

the junction. This is easily done on the module itself

and it would be a good idea to increase the security

distance on the left side by having the first module

to the left included in the stop block as well. A tower

operator will then ensure the crash-free passage of

the trains by aligning the turnouts, cutting off power

at conflicting tracks, and communicating with the

train engineers.

A good place for the tower operator is at the back

of the module overlooking all three approaching

sides free of obstructions such as operators or

visitors while being out of the way of passing

operators. A tall chair with the required electrical

switches and push buttons mounted on a panel

within a comfortable reaching distance makes a

perfect working environment. It is recommended to

have the panel separate from the module for easier

transportation and handling.

While it is possible to have the turnouts thrown by

hand it is recommended to install switch motors

with the wiring type indicated. Adding turnout

position feedback would even allow a remote CTC-

like control.

These two track plans use

grade crossings over the main

lines. While that has an impact on

operation, it is far easier than

building an overpass for the

branch line.

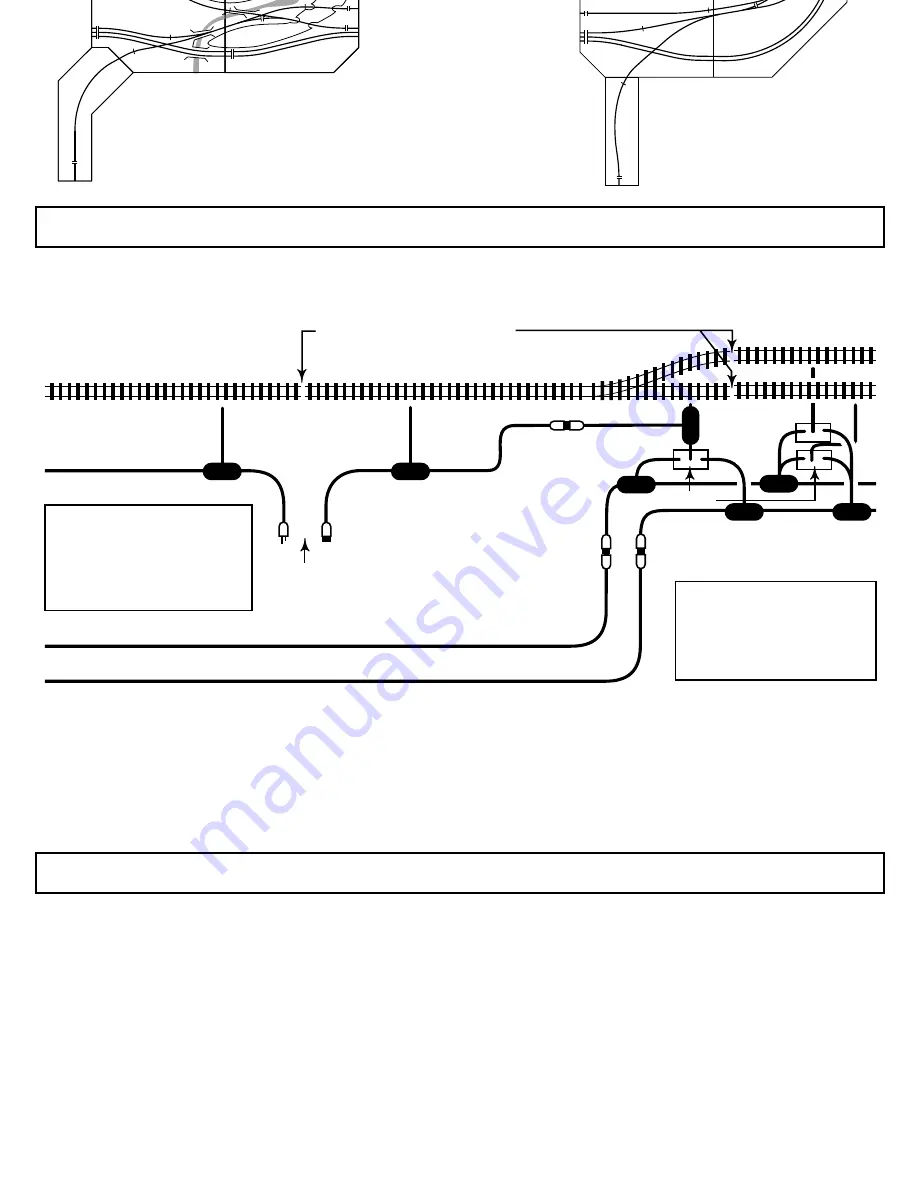

Standard wiring The most simple

way to control a oNeTRAK layout is

to have all tracks fed by the same

throttle. This might be a good idea

for small layouts. With a growing

number of modules there will be a

demand to run more than one train

simultaneously.

Installing several independant

blocks, each having its own throttle,

will allow multiple train operation.

But trains bypassing each other at

sidings will cause major headaches

for the operators and running trains

by time table will not work well.

Two Cab Control The sketch on

this page shows how two power

feeders running through a whole part

of the layout can be used to allow

usage of the same throttle while

passing other trains. By using radio

controlled throttles for left and right

“global”, an engineer will be able to

walk along his train and give himself

control for specific parts of the layout

by throwing the DPDT switches

accordingly. The DPDT switches

can, but do not have to be, integrated

into the wiring of single track

modules. It's recommended to

provide for this wiring while building

modules with sidings and yards.

Siding

Main

OS-Section

Mainline

Mainline

Isolated rail joiners on both sides

Red Line feeder wires

“Global” Left feeder wires (Colorcode: Black)

“Global” Right feeder wires (Colorcode: Magenta)

DPDT-Switches

Gaps in feeder wires through open connectors

This plug can be used for

“global” or local power supply.

Standard wiring single track module(s)

“Global” power supply

through separate wiring

“Global” power supply

through module wiring

The term “global” is introduced for

a power supply not directly

connected with a specific portion

of track. Before operating with

“global” power, one must use

switches to activate a connection.

With conventional Two Cab

Control the cabs are named "A"

and "B". Using horizontally

mounted DPDT switches yields

the names of two “global” power

supplies to be “Left” and “Right”.