113903G -System Installation Manual

20

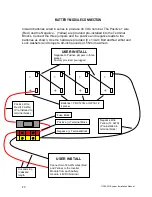

BATTERY MODULE CONNECTION

Install 4 batteries wired in series to produce 48 VDC nominal. The Po wire

(Red) and the Negative - (Yellow) are provided pre-installed into the Terminal

Blocks. Connect the three jumpers and the positive and negative leads to the

batteries as shown. Use the hardware provided (8 x 1/4-20 Bolt and Nut w/flat and

Lock washers) and torque to 40-inch pounds (4.5 Nm) maximum.

+

-

-

+

+

+

-

-

USER INSTALL

Negative to Positive jumpers in three

places.

Factory provided, pre-lugged.

Batteries = PRC1235L or NP33-12

4 piece

s

USER INSTALL

Connect two 12 AWG wires (Red

and Yellow) to the Inverter

Module from each battery

module. 48VDC Nominal.

Positive Wire

Red (12 AWG)

(Pre-Installed to

terminal block)

Negative Wire

Yellow (12 AWG)

(Pre-Installed to

terminal block)

Fuse Block

Positive (+) Terminal Block

Negative (-) Terminal Block

Cut and strip

to desired

length