PRO SERIES WALK-BEHIND TROWELS • OPERATION MANUAL — REV. #0 (9/21/17) — PAGE 43

General maintenance practices are crucial to the

performance and longevity of your trowel. This equipment

requires routine cleaning, lubrication, and inspection of

components for wear or damage.

Refer to Table 6 and Table 7 to schedule engine and trowel

maintenance. The following maintenance procedures can

prevent serious trowel malfunction or damage.

DANGER

NEVER use gasoline or low flash point

solvents to clean the engine or any of

its components. The possibility exists

of

fire or explosion which can damage

the equipment and cause

severe bodily

harm or even DEATH.

WARNING

Some maintenance operations may

require a running engine.

ALWAYS

make sure the maintenance area

is well ventilated. Gasoline engine

exhaust contains

poisonous carbon

monoxide gas that can result in

unconsciousness and/or DEATH

when inhaled.

CAUTION

NEVER attempt to service a hot engine.

ALWAYS allow the engine to cool before

servicing.

CAUTION

ALWAYS disconnect the spark plug wire from the

spark plug and secure it

away from the engine before

performing trowel maintenance or adjustments.

ENGINE MAINTENANCE

Inspect the engine daily for cleanliness, any oil or fuel

leakage, or loose fasteners.

Air Cleaner

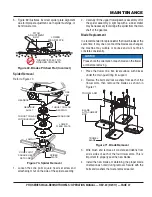

The engine air cleaner is equipped with a replaceable,

high-density, paper element. Refer to Figure 60 for air

cleaner maintenance.

Figure 60. Air Cleaner Maintenance

1. Remove the air cleaner cover and foam filter element.

2. Tap the paper filter element several times on a hard

surface to remove dirt, or blow compressed air, not

exceeding 30 lb/in² (207 kPa, 2.1 kgf/cm²), through

the filter element from the inside out.

NEVER brush off

dirt. Brushing will force dirt into the fibers. Replace the

paper filter element if it is excessively dirty.

CAUTION

ALWAYS wear personal protective

equipment such as approved safety

glasses, face shields, dust masks, or

respirators when cleaning air filters with

compressed air.

AIR CLEANER

COVER

PAPER FILTER

ELEMENT

BLOW COMPRESSED

AIR FROM THE

INSIDE OUT

FOAM FILTER

ELEMENT

GASKET

WING NUT

MAINTENANCE