PRO SERIES WALK-BEHIND TROWELS • OPERATION MANUAL — REV. #0 (9/21/17) — PAGE 47

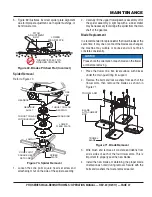

5. Figure 69 illustrates incorrect spider plate alignment

due to improper adjustment, worn spider bushings, or

bent trowel arms.

Figure 69. Blades Pitched Flat (Incorrect)

Spider Removal

Refer to Figure 70.

Figure 70. Spider Removal

1. Loosen the cone point square head set screw and

attached jam nut on the side of the spider assembly.

NO

LOWER

WEAR PLATE

PITCH

ADJUSTMENT

BOLT

“DISHED” EFFECT ON

FINISHED CONCRETE

GEARBOX

GEARBOX

SHAFT

THRUST COLLAR

BEARING

THRUST COLLAR

WITH BUSHING

LOWER

WEAR PLATE

SPIDER

PLATE

WEAR RING

YOKE

ARM

JAM NUT

CONE POINT

SQUARE HEAD

SET SCREW

2. Carefully lift the upper trowel/gearbox assembly off of

the spider assembly. A light tap with a rubber mallet

may be necessary to dislodge the spider from the main

shaft of the gearbox.

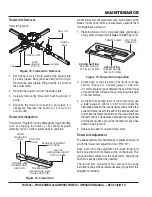

Blade Replacement

It is recommended to replace

all of the trowel blades at the

same time. If only one or some of the blades are changed,

the machine may wobble or bounce and will not finish

concrete consistently.

1. Place the trowel on a flat, level surface, with blocks

under the main guard ring for support.

2. Remove the bolts and lock washers from each of the

trowel arms, then remove the blades as shown in

Figure 71.

Figure 71. Blade Removal

3. Wire brush and remove all concrete and debris from

all six sides of each of the four trowel arms. This is

important to properly seat the new blades.

4. Install the new blades, maintaining the proper blade

orientation as noted during removal. Secure with the

bolts and washers that were removed earlier.

NOTICE

Please note the orientation of each blade on the trowel

arm before removing.

TROWEL ARM

TROWEL

BLADE

BLADE

ATTACHMENT

BAR

MAINTENANCE