21

SERVICE AND MAINTENANCE

To remove the deck, proceed as follows:

1.

Move the tractor to a level surface, disengage the PTO, stop the engine, ENGAGE

the parking brake.

2.

Lower the deck by moving the deck lift lever into the bottom notch on the

right fender.

3.

For tractors with a manual PTO continue with step 4, for electric PTO models

skip ahead to step 8.

4.

Loosen, but do not remove the flange lock

nut on the right idler pulley and the hex

screw on the left idler pulley.

5.

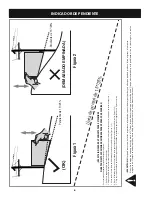

Remove the hex screw securing the engine

pulley keeper rod to the frame. See Figure

40.

6.

Slide the rod to the right to remove it.

NOTE:

Be careful not to damage the wire

harness when removing the rod.

7.

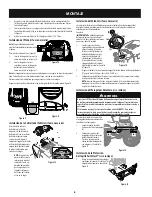

Remove the bow tie clip

that secures the PTO cable

to the bracket on the deck,

slide the PTO cable out of

the bracket and unhook

the spring from the idler

bracket. See Figure 41.

8.

Working on the right side

of the tractor, insert a 3⁄8”

drive ratchet wrench, set

to

tighten

, into square hole

found on the idler bracket. See Figure

42.

9.

Pivot the wrench forward to move the

deck drive pulley forward. See Figure

42.

10.

Carefully remove the belt from around

the PTO pulley.

11.

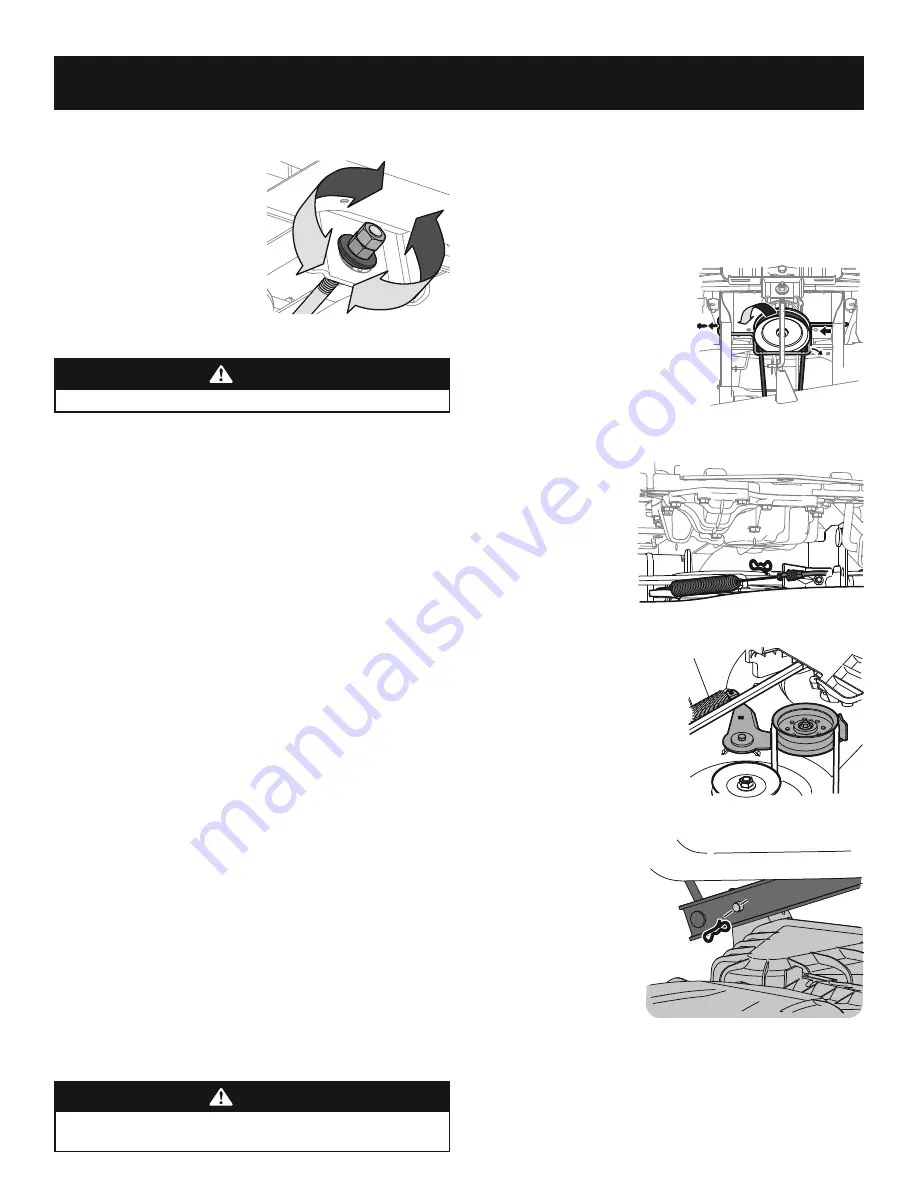

Looking at the deck from the left side

of the tractor, locate the bow-tie pin

on the rear left side of the

deck. See Figure 43.

12.

Remove the pin and slide the

deck pin out of the deck lift

arm. See Figure 43.

13.

Repeat steps 11-12 on the

tractor’s right side.

Figure 40

Figure 41

Figure 42

Figure 43

4. To

raise

the front of the deck, loosen the outer nut then tighten (thread

inward) the inner nut against the front hanger bracket. See Figure 39. When

proper adjustment is achieved, re-

tighten the outer nut to 25-30 ft.-lbs

(34-40.7 N-m).

5. To

lower

the front of the deck, loosen

the outer nut then loosen (thread

outward) the inner nut, away from the

front hanger bracket. See Figure 39.

When proper adjustment is achieved,

re-tighten the outer nut.

Adjusting the Deck Wheels

WARNING

Keep hands and feet away from the discharge opening of the cutting deck.

NOTE:

The deck wheels are an anti-scalp feature of the deck and are not designed to

support the weight of the deck.

The deck wheels should be approximately 1⁄4-1⁄2” (6.35-12.7mm) above the ground

when the deck is set in the desired height setting. To adjust the deck wheels see the

Assembly section for instructions.

Service

Electrical System

A fuse is installed to protect the tractor’s electrical system from damage caused

by excessive amperage. Always use the same capacity fuse for replacement. If the

electrical system does not function, check for a blown fuse.

If you have a recurring problem with blown fuses, have the tractor’s electrical system

checked by your authorized service dealer.

Relays and Switches

There are several safety switches in the electrical system. If a function of the safety

interlock system described earlier is not functioning properly, have the electrical

system checked by your authorized service dealer.

Parking Brake Adjustment

If the tractor does not come to a complete stop when the brake pedal is completely

depressed, or if the tractor’s rear wheels can roll with the parking brake applied

(and the hydrostatic relief valve open), the brake is in need of adjustment. See your

authorized service dealer to have the brake adjusted.

Hydrostatic Neutral Adjustment

If the tractor creeps forward or rearward when neither the forward nor reverse

pedal is depressed, contact your local authorized dealer to have the neutral setting

properly adjusted.

Wheel Alignment

If your tractor pulls to one side or is out of alignment, a wheel alignment might be

necessary. Contact an authorized service dealer to have the wheels properly aligned.

Deck Removal

WARNING

Use caution to avoid pinching your fingers when rolling the belt off the PTO

pulley.

Figure 39