21

Parking Brake Adjustment

WARNING:

Never attempt to adjust the

brakes while the engine is running. Always

disengage PTO, move speed control lever

into neutral position, stop engine and remove

key to prevent unintended starting.

If the tractor does not come to a complete stop when

the brake pedal is completely depressed, or if the

tractor’s rear wheels can roll with the parking brake

applied (and the hydrostatic bypass rod pulled out), the

brake is in need of adjustment. The brake disc can be

found on the right side of the transmission in the rear of

the tractor. Adjust if necessary as follows:

NOTE:

A replacement cotter pin (part no. 714-0111)

is needed to complete this adjustment. Have one on

hand before proceeding.

•

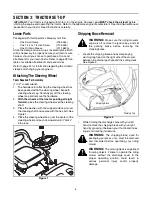

Looking at the transmission from the right side of

the tractor, locate the compression spring and

brake disc. See Figure 18.

Figure 18

•

Carefully remove the cotter pin from the crown nut

on the right side of the brake assembly.

•

Using a feeler gauge, check the gap between the

brake disc and the brake puck. Proper gap is .011".

•

Tighten the crown nut until the proper gap is

achieved.

•

Insert the replacement cotter pin into the crown nut.

Drag Link Adjustment

If the tractor turns tighter in one direction than the other,

or if either the drag link and ball joint are being replaced

due to damage or wear, the drag link may need to be

adjusted. To do so, proceed as follows:

•

Place the steering wheel in position for straight-

ahead travel.

•

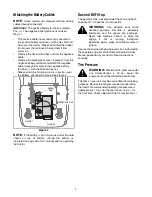

Remove the lock nut which secures the ball joint to

the steering arm. See Figure 19.

Figure 19

•

Lift the ball joint out of the steering arm and re-

position both front tires for straight-ahead travel.

•

Loosen the jam nut (See Figure 19) and thread the

ball joint either inward or outward until it aligns with

the hole in the steering arm.

•

Confirm that both the steering wheel and the front

tires are still positioned for straight-ahead travel

before reinserting the ball joint into the steering arm

and securing it with the lock nut removed earlier.

•

Re-tighten the jam nut loosened earlier.

Crown Nut

NOTE:

Rear, right wheel not shown for clarity

Brake Disc

Lock Nut

Steering Arm

Drag Link

Jam Nut

Ball Joint

Summary of Contents for 791

Page 29: ...29 NOTES ...

Page 30: ...30 NOTES ...