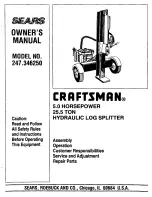

Controls & Features

4

11

Cylinder

Log Dislodger

Control Handle

Wedge

Beam Assembly

Log

Tray

Vertical

Beam

Lock

Jack Stand

Tongue

Horizontal

Beam Lock

End Plate

Tail Light

Figure 4-1

Engine Controls

See the Engine Operator’s Manual for the location and function

of the controls on the engine.

Beam Locks

These two locks, as their name suggests, are used to secure the

beam in the horizontal or the vertical position. The vertical beam

lock is located next to the engine. The horizontal beam lock is

located on the beam support latch bracket.

Control Handle

The control handle has three positions; Forward, Neutral and

Reverse. See the Operation section for instructions.

Wedge

The wedge is used to split the wood.

End Plate

The end plate holds the log in place while the wedge splits the

log.

Log Dislodger

The log dislodger is designed to remove any partially split wood

from the wedge. This may occur while splitting large diameter

wood or freshly cut wood.

Log Tray

The log tray is designed to catch the log after it is split.

Tongue

The tongue is used to attach to a towing vehicle for

transportation.

Tail Light (If so equipped)

The tail light’s are located on the back of the frame for

transportation and towing purposes.

WARNING!

Do not tow faster than 45mph and

check the local, state, and federal requirements

before towing on any public road.