4.

Visually inspect the spark plug. Discard the spark plug

if there is apparent wear, or if the insulator is cracked or

chipped. Replace the plug if the electrodes are pitted,

burned or fouled with deposits.

5.

Clean the spark plug with a wire brush if it is to be reused.

6.

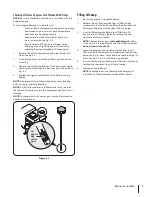

Measure the plug gap with a feeler gauge. Correct as

necessary by bending side electrode. See Fig. 6-3. The gap

should be set to 0.030 in. (0.76mm).

7.

Check that the spark plug washer is in good condition

8.

Thread the spark plug in by hand to prevent cross-

threading.

9.

After the spark plug is seated, tighten with a spark plug

wrench to compress the washer.

NOTE:

When installing a new spark plug, tighten 1⁄2 turn

after the spark plug seats to compress the washer. When

reinstalling a used spark plug, tighten 1⁄8-1⁄4 turn after the

spark plug seats to compress the washer.

NOTE:

The spark plug must be securely tightened. An

improperly tightened spark plug can become very hot and

may damage the engine.

Air Filter

NOTE:

Not all engines have air filters, such as engines used for

snow throwers. Service the air filter if one is present.

Paper filters cannot be cleaned and must be replaced once a

year or every 10 operating hours; more often if used in extremely

dusty conditions.

WARNING!

Never use gasoline or low flash point

solvents for cleaning the air cleaner element. A fire

or explosion could result.

NOTE:

Never run the engines that have air filters without them.

Rapid engine wear can result.

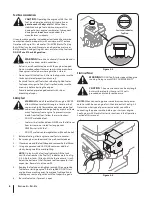

1.

Press the tab on the air filter cover and lift the cover, or

un-thread the thumbscrews, depending on the model of

engine you have. See Fig. 6-4.

2.

Replace paper element when dirty or damaged. Clean

foam element or replace when damaged.

3.

To clean foam element, separate it from the paper element

and wash in liquid detergent and water. Allow to dry

thoroughly before using. Do not oil the foam element.

Adjustments

DO NOT make any engine adjustments. Factory settings are

satisfactory for most conditions. If adjustments are needed,

contact your Authorized Servicing Dealer.

Carburetor

If you think you carburetor needs adjusting, see your nearest

Authorized Servicing Dealer. Engine performance should NOT be

affected at altitudes up to 7,000 feet (2,134 meters). For operation

at higher elevations, contact your Authorized Servicing Dealer

Alternator

(if equipped)

Contact your Authorized Servicing Dealer for alternator related

electrical problems such as:

•

Inoperative Starter

•

Discharged Battery

•

Fuse Replacement

•

Alternator Maintenance/Repairs

Engine Speed

WARNING!

To avoid serious injury or death, DO

NOT modify engine in any way. Tampering with the

governor setting can lead to a runaway engine and

cause it to operate at unsafe speeds. NEVER tamper

with the factory setting of the engine governor.

WARNING!

Running the engine faster than the

speed set at the factory can be dangerous and will

VOID THE ENGINE WARRANTY.

Removing Snow from the Engine

After each use, remove snow from the following areas:

•

Oil Fill Cap Dipstick

•

Fuel Fill Cap

•

Recoil Starter/Flywheel Screen

•

Linkage

•

Guards

•

Spark Plug Connection (if visible).

•

Electric Starter Switch Box, if present (see the

equipment Operator’s Manual instructions).

NOTE:

See the equipment Operator’s Manual instructions

for proper location of fuel fill cap and control lever.

1.

Removing snow will ease operation of the recoil starter

rope and reduce the risk of water contamination when

opening the fuel fill cap.

NOTE:

For more information about recoil starters, see

Engine’s with Recoil Starters in the Operation Section of

this manual.

Figure 6-4

15

S

ection

6 — M

aintenance

Summary of Contents for 165-SUC

Page 24: ...Notes 21...