9

EN

SPECIALIZED TECHNICIANS INSTRUCTIONS

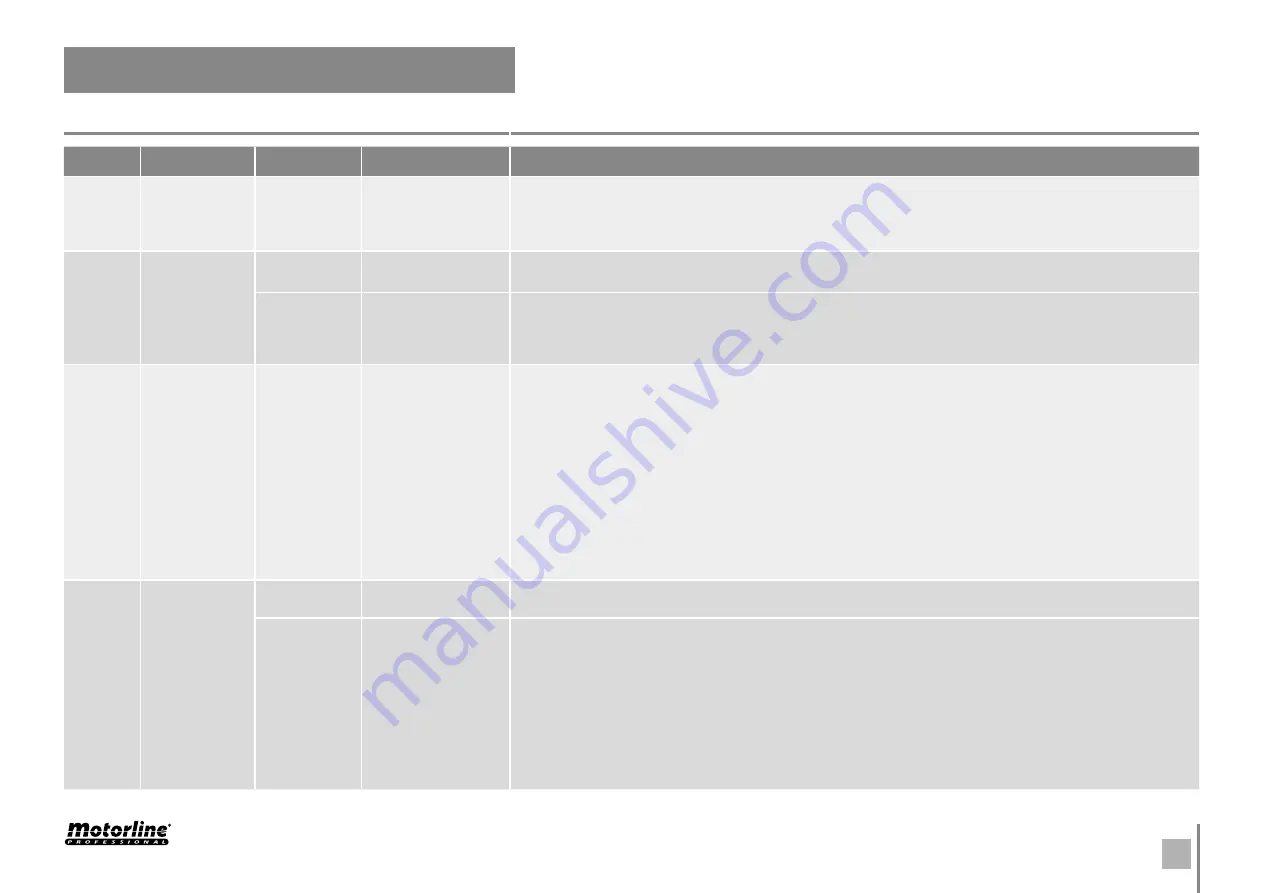

05. TROUBLESHOOTING

FINAL CONSUMERS INSTRUCTIONS

Problem

Procedure

Behavior

Procedure II

Discovering the origin of the problem

• Barrier

doesn't work.

• Make sure you

have power in the

automation control

board and if it is

working properly.

• Still not working.

• Consult a qualified

MOTORLINE technician.

• Barrier

doesn’t move

but makes

noise.

• Unlock barrier and

move boom by hand

to check for mechani-

cal problems on the

movement.

• Encountered

problems?

• Consult a qualified

MOTORLINE technician.

1 • Check all motion axis and associated motion systems related with the barrier to find out what is the problem.

• Boom moves

easily?

• Consult a qualified

MOTORLINE technician.

• Barrier

opens but

doesn’t close.

• Unlock motor and

move boom by hand

to closed position.

Lock motor again and

turn off power supply

for 5 seconds. Recon-

nect it and send order

to open barrier using

transmitter.

• Barrier opened but

didn’t close again.

1 • Check if there is any

obstacle in front of the

photocells;

2 • Check if any of the

control devices (key selector,

push button, video intercom,

etc.) of the barrier are jam-

med and sending permanent

signal to control unit;

3 • Consult a qualified MO-

TORLINE technician.

• Barrier

doesn’t make

complete

route.

• Unlock barrier and

move boom by hand

to check for mechani-

cal problems on the

barrier.

• Encountered

problems?

• Consult a qualified

MOTORLINE technician.

1 • Check all motion axis and associated motion systems related with the barrier to find out what is the problem.

• Boom moves

easily?

• Consult a qualified

MOTORLINE technician.

1 • Open control box and check

if it has 230V/110V/24V power

supply;

2 • Check input fuses;

3 • Disconnect barrier from

control board and test them by

connecting directly to power

supply in order to find out if they

have problems (see page 7B).

4 • If the barrier works, the

problem is on the control board.

Pull it out and send it to our

MOTORLINE technical services

for diagnosis;

5 • If the barrier doesn’t work,

remove them from installation

site and send to our MOTORLINE

technical services for diagnosis.

1 • Check capacitors, testing

operator with new capacitor;

2 • If capacitors are not the

problem, disconnect motor from

control board and it them by

connecting directly to power

supply in order to find out if it

has problems (see page 7B).

3 • If the motor works, the

problem is from control board.

Pull it out and send it to our

MOTORLINE technical services

for diagnosis;

4 • If the motor doesn’t work,

remove them from installation

site and send to our MOTORLINE

technical services for diagnosis.

All MOTORLINE control boards

have LEDs that easily allow to

conclude which devices are with

anomalies. All safety devices

LEDs (DS) in normal situations

remain On. All "START" circuits

LEDs in normal situations remain

Off.

If LEDs devices are not all On,

there is some security systems

malfunction (photocells,

safety edges), etc. If "START"

circuits LEDs are turn On, there

is a control device sending

permanent signal.

A) SECURITY SYSTEMS:

1 • Close with a shunt all

safety systems on the control

board (check manual of the

control board in question). If

the automated system starts

working normally check for the

problematic device.

2 • Remove one shunt at a time

until you find the malfunction

device .

3 • Replace it for a functional

device and check if the motor

works correctly with all the other

devices. If you find another one

defective, follow the same steps

until you find all the problems.

B) START SYSTEMS:

1 • Disconnect all wires from

START terminal input (terminal 3

of CN3 connector).

2 • If the LED turned Off, try

reconnecting one device at a

time until you find the defective

device.

NOTE:

In case procedures described in

sections A) and B) don’t result,

remove control board and send

to our technical services for

diagnosis.

1 • Check capacitors, testing

with new capacitors;

2 • If capacitors are not the

problem, disconnect motor

from control board and test it

by connecting directly to power

supply in order to find out if it is

broken;

3 • If the motor doesn’t work,

remove it from installation site

and send to our MOTORLINE

technical services for diagnosis.

4 • If motor work well and move

barrier at full force during the

entire course, the problem is

from controller. Set force using

trimmer on the board. Make a

new working time programming

, giving suffient time for opening

and closing with appropriate

force (page 08.B of this manual

for MBM6 230V).

5 • If this doesn’t work, remove

control unit and send it to

MOTORLINE technical services

services.

NOTE: Setting force of the

controller should be sufficient to

make the barrier open and close

without stopping, but should

stop and invert with a little effort

from a person. In case of safety

systems failure, the barrier shall

never cause physical damaged

to obstacles (vehicles, people,

etc.).