AT 2200 Air Head Crimp Tool

Doc. No. 64005-1500

Release Date: 01-16-03

UNCONTROLLED COPY

Page 3 of 7

Revision: C

Revision Date: 01-10-06

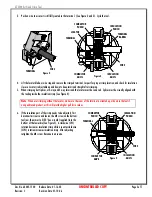

TERMINAL

BARREL

TERMINAL

LOCATOR

WIRE

CONDUCTOR

PUNCH

INSULATION

ANVIL

Figure 3

INSULATION

PUNCH

CONDUCTOR

ANVIL

Figure 2

TERMINAL

WIRE

3. Push on wire to assure it is still fully seated in the terminal. (See Figure 2 and 3). Cycle the tool.

4. Lift the locator blade or wire stop and remove the crimped terminal. Inspect for proper crimp location, and check for insulation

closure. Locator is adjustable up and down to keep terminals straight after crimping.

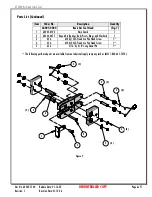

5. When crimping butt splices, or 3-way and 4-way terminals the locator must be removed. Splices must be visually aligned with

the tooling inside the insulation crimp (See Figure 4).

Note

: Whenever crimping without the locator, make sure the seam of the terminal is oriented up or down in the tool if

using unbrazed product, as this will provide higher pull force values.

6. If the insulation part of the crimp needs to be adjusted, first

disconnect air source and loosen the M4 screw on the bottom

tool jaw, then insert a 3/32” hex wrench (supplied) into the

bottom of the lower die (See Figure 5). A clockwise (CW)

rotation decreases insulation crimp while a counter-clockwise

(CCW) rotation increases insulation crimp. After adjusting

retighten the M4 screw. Reconnect air source.

CONDUCTOR

ANVIL

Figure 4

INSULATION

ANVIL

WIRE

INSULATION

PUNCH

CONDUCTOR

PUNCH

TERMINAL