operate the valve about 3 times to ensure

b. S

to

c. A

in about 3 times to ensure the

function.

the function.

ystems hydrostatic test

Before delivery, valves are tested 1.5 times

the allowable working pressure at ambient

temperature in open position. After

installation, the pipe line system may

subject to system tests, as condition not

exceed the maximum working pressure.

fter pressure testing, user shall operate the

valve aga

7.

a.

ion, such as pressure, temperature and

b.

the product to avoid danger in the

future.

Dangers of inappropriate use

Never uses the product exceed its allowed

condit

fluid.

If the product has any inappropriate use, the

product was damage however there are no

signals occurs immediately. User shall

change

8.

a.

re effect and high-temperature

effect etc.

b.

ement between stem and

stem packing.

c.

em

ry,

(1)

valve must follow the

(2)

and inflammability

(3)

dure is protecting the surface of the

(4)

the seat retainer fall down from end

(5)

d the ball

d

ion, maintenance, and

(1

damage factors as far as possible as

(2

Maintenance

Maintenance frequency

The maintenance frequency is determined

upon the application. User shall consider the

time interval depend on the kinds of fluid,

flow velocity, operation frequency,

high-pressu

Adjustment of the Gland

Tighten the gland nut about

¼

turn

periodically to compensate for the wear

caused by mov

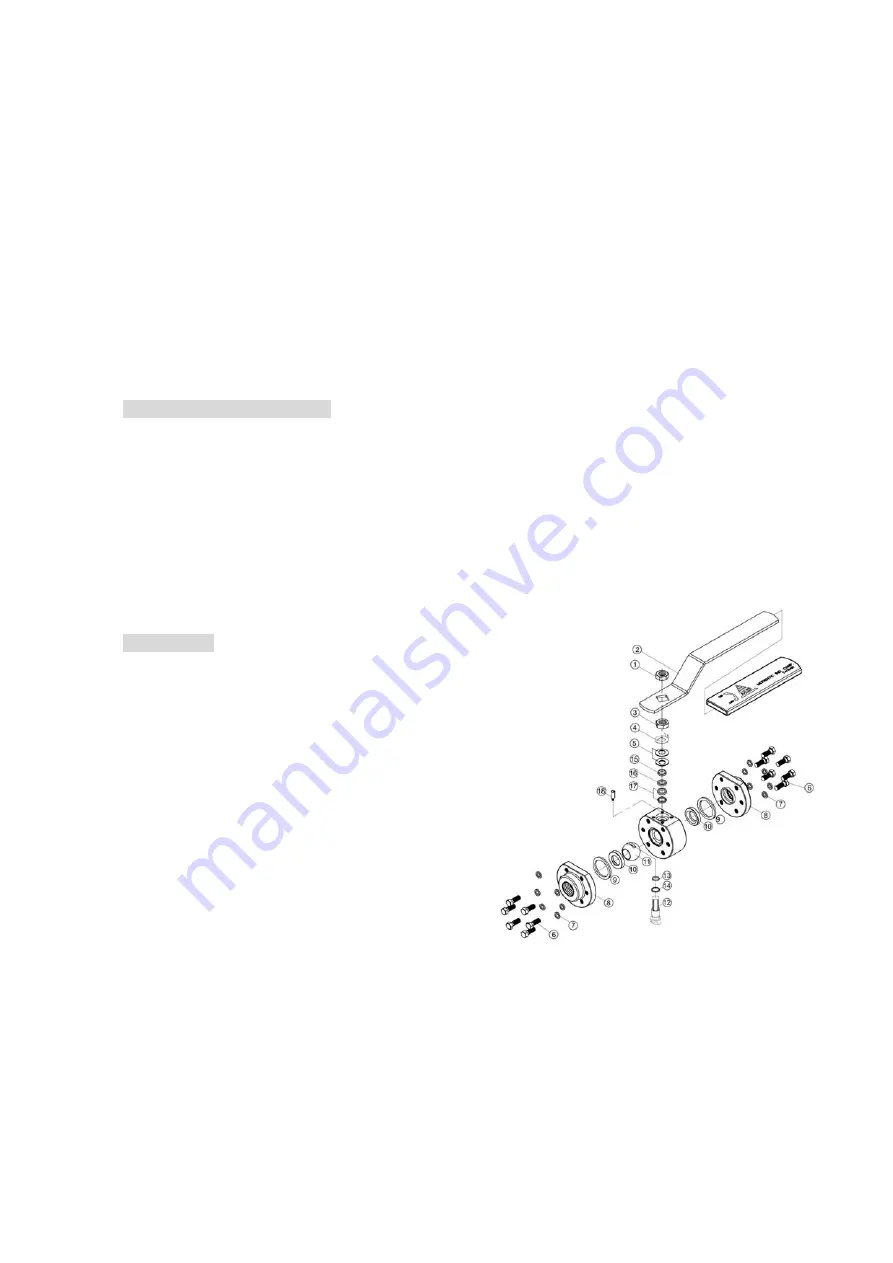

Disass

bly

(NOTE

If complete disassembly is necessa

replacement of all seats and seals is recommended.)

To dismantle the

procedure below.

It doesn’t matter where the position of

valve located is; usually it contained the

seal up fluid, so operator must be very

carefully when moving the valve on the

pipe. It must open the ball a little and let

the fluid come out slowly, it also need to

watch out the poisonous

objects if there is any.

It must turn the ball in the close position

before dismantle the valve. The ball cannot

be taken out from valve body if the ball is in

the open or semi-open position. The right

position for store the valve is put the flange

end on the ground. If it is a valve with the

hand wheel, than it must dismantle the

hand

wheel from the valve

first than put

the valve flange end on the ground. This

proce

ball.

To dismantle the valve body and end cap,

release retainer with a special tool. It

must be careful to dismantle the ball to

avoid

cap.

To lift the ball by hoist, it must make the

protection on corner to avoi

damaged by metal contacted.

. Parts inspect

replacement:

) Check the surface of ball if it is scraped

use the PT for inspection if necessary. If

there is any damage on the surface, then find

out the root cause such as the dirt fluid…etc.

avoid the

we can .

) The damage of the ball surface, to gauge if it

is locate on the contacting area of ball and ball

5

Summary of Contents for 3PC

Page 5: ...f Dimensions Parts List 3 ...

Page 10: ...8 ...