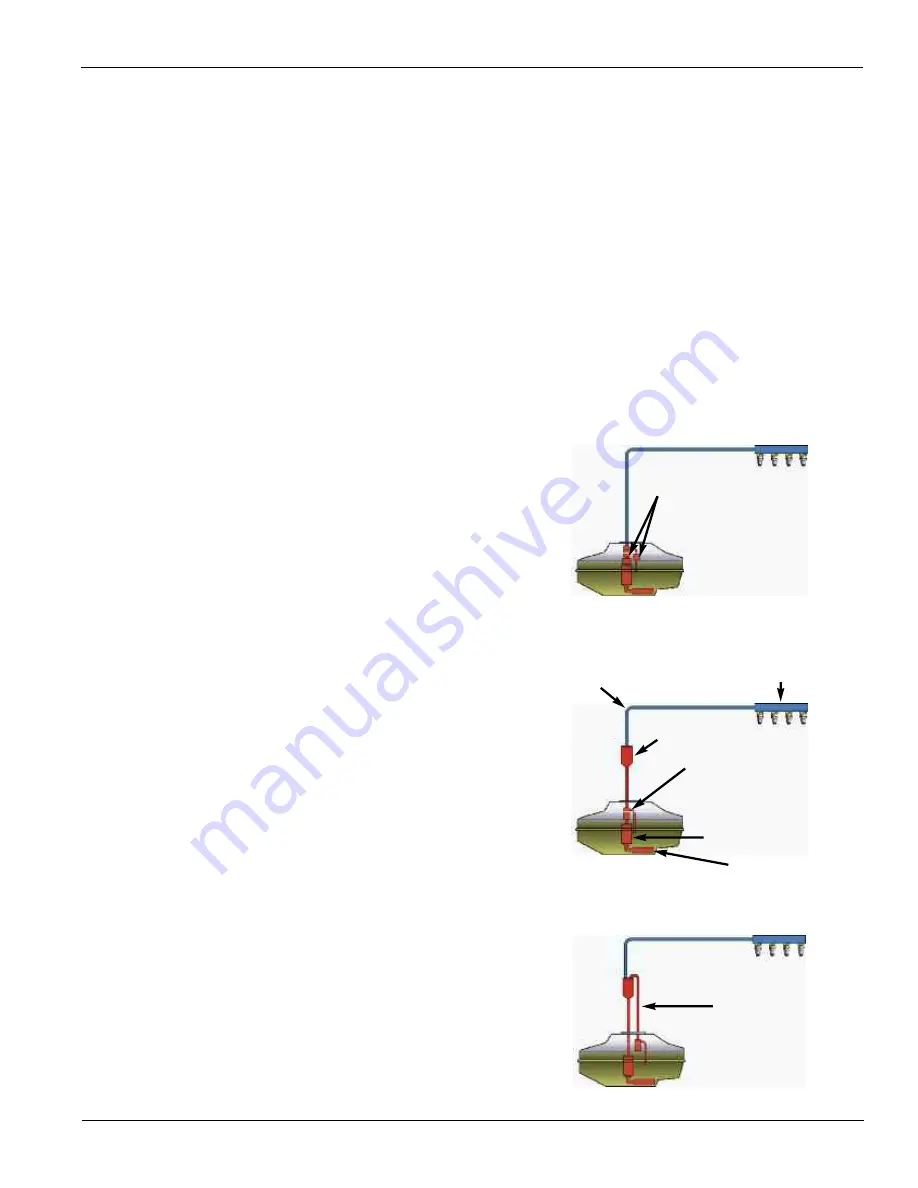

Fig. 25

Fig. 24

Fig. 23

Page Number - 15

Returnless fuel systems (mechanically regulated) were pioneered by

Chrysler in the mid-90s. Since that date, other car manufacturers

have been implementing returnless systems onto their cars. Now

returnless systems are common on most all new cars and light trucks.

Mechanically Regulated

In the case of mechanically regulated returnless systems, the term

“returnless” can be misleading. Like a return system, the fuel pump

operates continuously, producing an uncontrolled output. Since the

engine will only use a portion of the total pump output, the excess

fuel must still be returned. This is done either in the tank, or the fuel

is routed just outside the tank for filtering, and then returned.

Mechanically regulated systems utilize a spring operated pressure

regulator mounted in the tank as part of the pump module. The regu-

lator is very similar to those used in return systems, except it is not

vacuum- or pressure-modulated. Fuel pressure in returnless systems

is typically higher than return systems to compensate for the lack of

modulation, and to help prevent the fuel from boiling in the fuel rail.

Mechanically regulated returnless fuel systems employ one of three

basic concepts to filter the fuel and accommodate the excess output

of the pump. All three methods utilize a fuel pump module with

built-in pressure regulator. The FST is very capable of diagnosing

a malfunction of any of the three variations. However the type of

return/filtration method employed has a significant impact on the

FST’s capability to pinpoint the malfunction. Refer to the Testing and

Diagnostics section later in this manual for the proper application of

the FST in diagnosing each system. In some cases, pinpointing the

exact cause of the malfunction may be irrelevant because the pump,

filter, and pressure regulator are all part of a module assembly that

must be replaced as a complete unit.

In-tank Filtering/In-tank Return

This method involves filtering and returning the excess fuel without it

leaving the tank (Fig. 23). Both pressure regulator and filter are part of

the fuel pump module. Filtering is accomplished in one of three ways:

•

A pre-pump filter is used to filter the fuel before it enters the pump.

•

The filter is located after the pressure regulator, where it filters the

unused fuel before mixing it back into the fuel reserve.

•

The filter is located in the pump module, between the pump and

the regulator.

Some manufacturers have designed in-tank filter/regulator systems

that use some variation or combination of these three concepts to

produce what they consider to be the most effective system. In cases

involving in-tank filtering and return, all of the control components are

included as part of the pump module assembly, and are most likely

replaced as a complete unit.

External Filtering/In-tank Return

This system of fuel filtration and return uses a pressure regulator on

the pump module to regulate fuel pressure and return unused fuel

before it leaves the tank. The main filtration is handled by an inline

filter mounted externally between the tank and the fuel rail (Fig. 24).

External Filtering/External Return

In this type of filtering/return system, the fuel is pumped out of the

tank to an external filter mounted on or near the tank (Fig. 25). The fil-

ter serves as a sort of manifold, with a single fuel supply line running

into one end of the filter, and two fuel lines exiting the filter. One of the

exiting lines supplies fuel to the engine, while the other returns the

unused fuel to the regulator and the tank.

Fuel Filter

Fuel Filter

Pressure Regulator

Fuel Pump

Inlet Strainer/Sock

Fuel Return

Fuel Rail

Fuel Supply Line