Page Number - 8

Form 801625

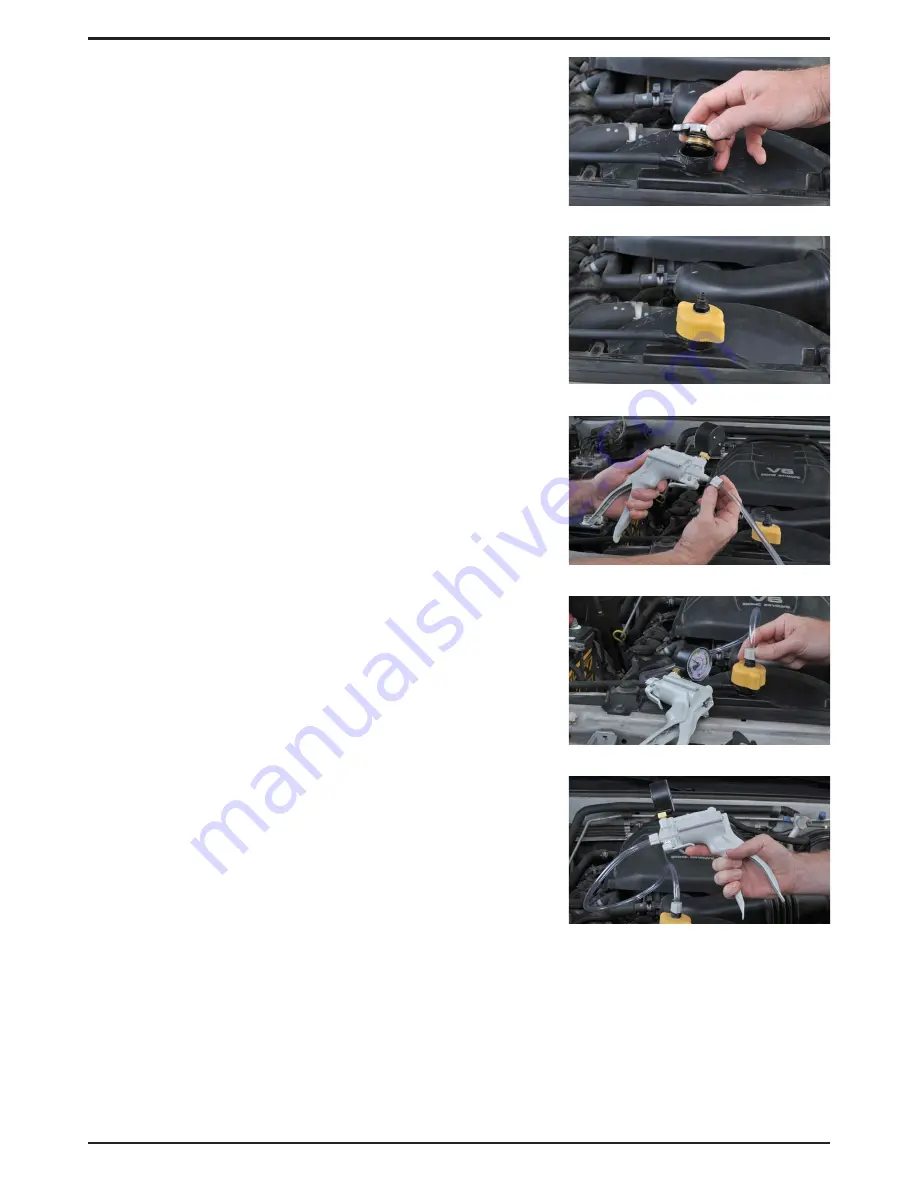

Fig. 6

Fig. 7

Fig. 8

Dynamic Pressure Test (Engine On)

For diagnosing:

Cooling system leaks

Blown head gasket

Cylinder head damage

Cracked block

Set-up & Procedure:

1. Ensure the cooling system is cool and not pressurized.

Carefully remove the radiator or coolant bottle pressure cap

(Fig. 6).

2. Check to see that the radiator or coolant bottle is filled to

the proper level, and check hoses for visual damage or

leaks. Fill and repair as necessary prior to testing.

3. Select the correct Cooling System Adapter for the

application.

4. Apply water or coolant to the rubber gasket and/or o-ring

on the adapter, and install the adapter in place of the

pressure cap (Fig. 7).

5. Secure one end of the clear hose to the pressure pump

using the compression nut (Fig. 8).

6. Secure the second end of the hose to the cooling system test

adapter using the compression nut (Fig. 9).

7. Note the operating pressure of the cooling system

indicated on the cap or in the vehicle repair manual.

8. Start the vehicle engine and monitor the pressure gauge.

An immediate and rapid pressure buildup is an indication of

a breach between a cylinder and the cooling system, most

likely due to a blown head gasket. Immediately turn off the

engine and release the pressure in the system by pressing

the Pressure Relief Lever located on pump (Fig. 10). Dis-

connect the test equipment and replace the head gasket.

If no immediate or rapid pressure buildup is indicated,

operate the pressure pump to bring the system to normal

operating pressure. If the needle on the pressure gauge

vibrates rapidly, this is an indication of a smaller compres-

sion or combustion leak into the cooling system possibly

caused by a damaged block or head. Turn off the engine,

carefully release the pressure in the system by pressing

the Pressure Relief Lever located on pump (Fig 10).

Disconnect the test equipment and consider replacing

the head gasket.

9. If no abnormal pressure buildup is indicated, carefully

release the pressure in the system by pressing the Pres-

sure Relief Lever located on the pump (Fig. 10). Let the

engine run until it reaches normal operating pressure and

temperature. Turn off the engine and allow it to cool with

pressure still applied. Check for leaks as the engine cools.

A leak caused by a slightly loose hose clamp or a stuck

Fig. 9

Fig. 10

Summary of Contents for MV4560

Page 39: ...Document 801625 Page num ro 39...