600

600

175

(210)

175

(210)

950(1020)

25

330

370

4

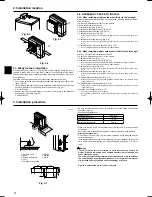

2. Installation location

Fig. 2-3

Fig. 2-2

Fig. 2-4

Fig. 3-1

3. Installation procedure

• Be sure to install the unit in a solid, level surface to prevent rattling noises during

operation. (Fig. 3-1)

<Foundation speci

fi

cations>

Foundation bolt

M10 (3/8")

Thickness of concrete

120 mm

Length of bolt

70 mm

Weight-bearing capacity

320 kg

• Make sure that the length of the foundation bolt is within 30 mm from the surface

of the base.

• Secure the base of the unit

fi

rmly with 4 M10 foundation bolts in solid locations.

Installing the outdoor unit

• Do not block the vent. If the vent is blocked, operation will be hindered and the

unit may breakdown.

• If the additional

fi

xation of the unit is necessary, use the installation holes on the

back of the unit to attach wires, etc. with self-tapping screws (ø5 × 15 mm or

less).

Warning:

• The unit must be securely installed on a structure that can sustain its

weight. If the unit is mounted on an unstable structure, it may fall down and

cause damage or injuries.

• The unit must be installed according to the instructions in order to minimize

the risk of damage by earthquakes, typhoons, or strong winds. An improp-

erly installed unit may fall down and cause damage or injuries.

* Figures in parentheses are for 112/140 unit types.

(mm)

2.3. Windy location installation

When installing the outdoor unit on a rooftop or other location where the unit is

exposed to strong wind, do not face the air outlet of the unit directly into the winds.

Strong wind entering the air outlet may impede the normal air

fl

ow and it may result

in a malfunction.

The following shows three examples of precautions against strong winds.

1

Face the air outlet towards the nearest available wall keeping about 50 cm dis-

tance. (Fig. 2-2)

2

Install an optional air guide if the unit is installed in a location where strong winds

such as a typhoon, etc. may directly blow to the air outlet. (Fig. 2-3)

A

Air outlet guide

3

Position the unit so that the outlet air can blow at right angle to the seasonal

wind direction, if possible. (Fig. 2-4)

B

Wind direction

A

M10 (3/8") bolt

B

Base

C

As long as possible

D

Vent

E

Set deep in the ground

F

Max.30

G

Min.360

H

Min.10

2.4. NECESSARY SPACE TO INSTALL

2.4.1. When installing a single outdoor unit (Refer to the last page)

Minimum dimensions are as follows, except for Max., meaning Maximum dimen-

sions, indicated.

The

fi

gures in parentheses are for 112/140 models.

Refer to the

fi

gures for each case.

1

Obstacles at rear only (Fig. 2-5)

2

Obstacles at rear and above only (Fig. 2-6)

3

Obstacles at rear and sides only (Fig. 2-7)

4

Obstacles at front only (Fig. 2-8)

*

When using an optional air outlet guide, the clearance for 112/140 models is 500 mm or

more.

5

Obstacles at front and rear only (Fig. 2-9)

*

When using an optional air outlet guide, the clearance for 112/140 models is 500 mm or

more.

6

Obstacles at rear, sides, and above only (Fig. 2-10)

•

Do not install the optional air outlet guides for upward air

fl

ow.

2.4.2. When installing multiple outdoor units (Refer to the last page)

Leave 10 mm space or more between the units.

The

fi

gures in parentheses are for 112/140 models.

1

Obstacles at rear only (Fig. 2-11)

2

Obstacles at rear and above only (Fig. 2-12)

•

No more than 3 units must be installed side by side. In addition, leave space as shown.

•

Do not install the optional air outlet guides for upward air

fl

ow.

3

Obstacles at front only (Fig. 2-13)

*

When using an optional air outlet guide, the clearance for 112/140 models is 1000 mm or

more.

4

Obstacles at front and rear only (Fig. 2-14)

*

When using an optional air outlet guide, the clearance for 112/140 models is 1000 mm or

more.

5

Single parallel unit arrangement (Fig. 2-15)

*

When using an optional air outlet guide installed for upward air

fl

ow, the clearance is 500

(1000) mm or more.

6

Multiple parallel unit arrangement (Fig. 2-16)

*

When using an optional air outlet guide installed for upward air

fl

ow, the clearance is 1000

(1500) mm or more.

7

Stacked unit arrangement (Fig. 2-17)

•

The units can be stacked up to 2 units high.

•

No more than 2 stacked units must be installed side by side. In addition, leave space as

shown.

01̲ BH79D067L02̲EN.indd 4

01̲ BH79D067L02̲EN.indd 4

2009/06/03 9:50:56

2009/06/03 9:50:56

Summary of Contents for PUHZ-HW*HA series

Page 8: ......