Chapter 5 Installation

5–3

5-1 Installation of servomotor

CAUTION

1. Do not hold the cables, axis or detector when transporting the servomotor.

Failure to observe this could lead to faults or injuries.

2. Securely fix the servomotor to the machine. Insufficient fixing could lead to

the servomotor deviating during operation. Failure to observe this could

lead to injuries.

3. When coupling to a servomotor shaft end, do not apply an impact by

hammering, etc. The detector could be damaged.

4. Never touch the rotary sections of the servomotor during operations. Install

a cover, etc., on the shaft.

5. Do not apply a load exceeding the tolerable load onto the servomotor shaft.

The shaft could break.

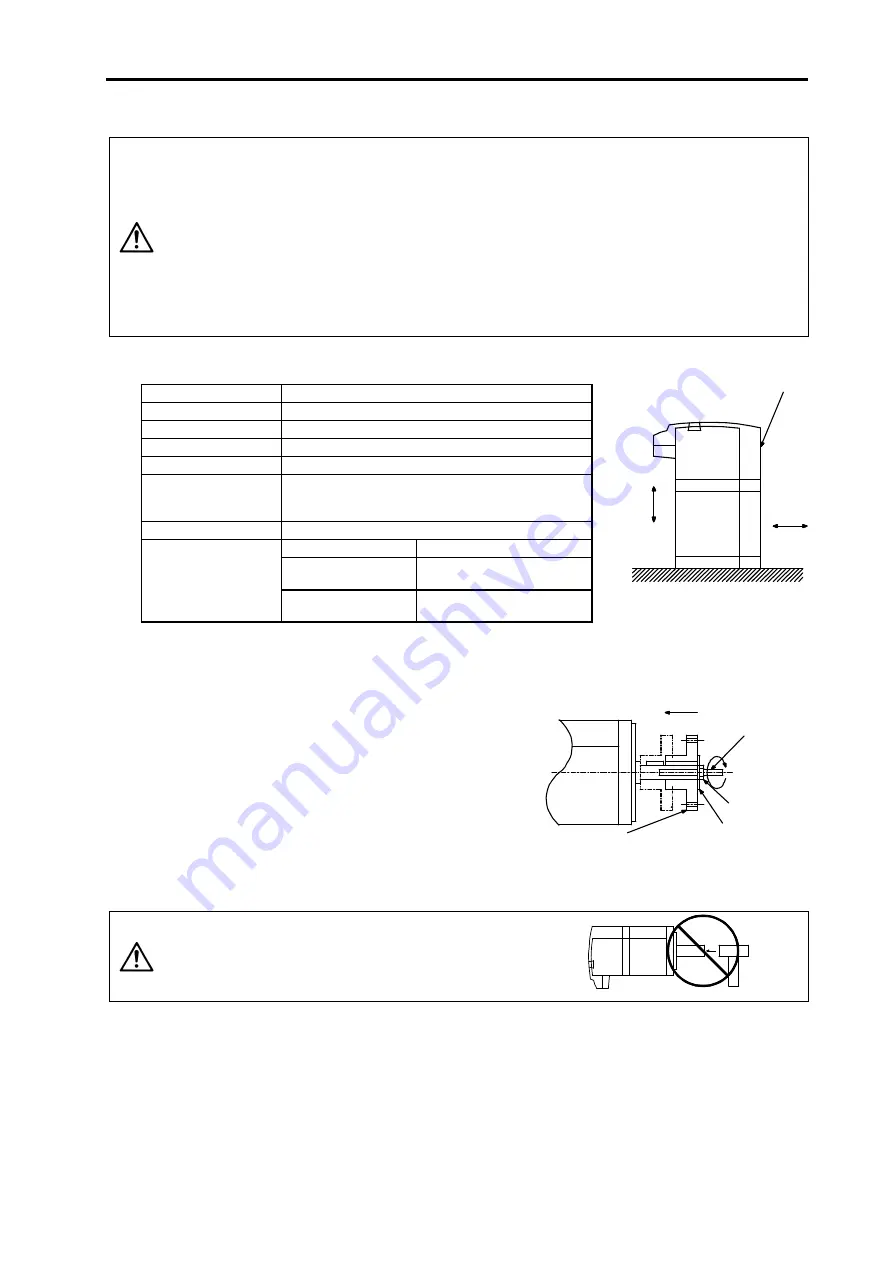

5-1-1 Environmental conditions

Environment

Conditions

Ambient temperature

0

°

C to +40

°

C (with no freezing)

Ambient humidity

80% RH or less (with no dew condensation)

Storage temperature

–20

°

C to +65

°

C (with no freezing)

Storage humidity

90% RH or less (with no dew condensation)

Atmosphere

•

Indoors (Where unit is not subject to direct sunlight)

•

With no corrosive gas or combustible gas.

•

With no oil mist or dust

Altitude

1000m or less above sea level

HS-MF

X, Y: 19.6m/s

2

(2G) or less

HS-RF

HS-SF 1kW or less

X: 9.8m/s

2

(1G) or less

Y: 24.5m/s

2

(2.5G) or less

Vibration

HS-SF 2kW

X: 19.6m/s

2

(2G) or less

Y: 49m/s

2

(5G) or less

5-1-2 Cautions for mounting load (prevention of impact on shaft)

(1) When using the servomotor with key way, use the

screw hole at the end of the shaft to mount the pulley

onto the shaft. To install, first place the double-end

stud into the shaft screw holes, contact the coupling

end surface against the washer, and press in as if

tightening with a nut. When the shaft does not have a

key way, use a frictional coupling, etc.

(2) When removing the pulley, use a pulley remover,

and make sure not to apply an impact on the shaft.

(3) Install a protective cover on the rotary sections such

as the pulley installed on the shaft to ensure safety.

(4) The direction of the detector installation on the

servomotor cannot be changed.

CAUTION

Never hammer the end of the shaft

during assembly.

5-1-3 Installation direction

There are no restrictions on the installation direction. Installation in any direction is possible, but as a

standard the servomotor is installed so that the motor power supply wire and detector cable cannon

plugs (lead-in wires) face downward. When the servomotor is not installed in the standard direction,

refer to section "5-1-5 Oil and waterproofing measures" and take the appropriate measures.

The brake plates may make a sliding sound when a servomotor with magnetic brake is installed with

the shaft facing upward, but this is not a fault.

Servomotor

Acceleration

X

Y

Servom o to r

D ou ble-end stud

N ut

W ash er

Pu lley