13-12

Useful advice for emergencies

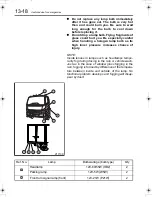

3. When a fuse is blown, be sure to replace it with

a spare fuse of the specified amperage (A).

NOTE:

After using a spare fuse, replenish it as soon as

possible.

CAUTION

•

If the cause of a blown fuse cannot be deter-

mined or the same fuse blows frequently,

have your vehicle inspected at an authorized

dealer.

•

Use care not to splash water on or around

the glove compartment. Should water be

splashed over the glove compartment, check

the inside of the compartment for water.

WARNING

Use genuine fuses of the specified amper-

ages. A fire could result if a fuse of incorrect

amperage is used.

Z11217

FKFM.book Page 12 Wednesday, January 28, 2009 9:21 AM

Summary of Contents for Fuso FK 2010

Page 1: ...Owner s Manua l Owner s Manual 2010 Model 2010 Model ...

Page 3: ......

Page 7: ......

Page 18: ...2 1 Locations in cab 2 3 Locations outside cab 2 4 2 Warning labels ...

Page 23: ......

Page 37: ...3 14 Opening and closing Pull latch and push it outward to open Rear quarter window Z14188 ...

Page 38: ...4 1 Seats 4 2 Seat belts 4 5 Steering wheel 4 9 4 Seat and steering wheel adjustments ...

Page 47: ......

Page 101: ......

Page 118: ...8 1 Anti lock brake system ABS 8 2 ABS warning lamp 8 4 8 ABS driving hints ...

Page 123: ......

Page 124: ...9 1 Heater 9 2 Air conditioner 9 7 9 Heating and air conditioning ...

Page 145: ......

Page 245: ......

Page 278: ...15 1 Maintenance schedule 15 2 Lubrication schedule 15 11 15 Maintenance schedule ...

Page 290: ...16 1 16 Alphabetical index ...

Page 293: ......

Page 295: ......

Page 297: ......

Page 362: ...Pub No MH996034 Owner s Manua l 2010 Model TOYO CF10884 DIC F101 BLACK FEBRUARY 09 ...