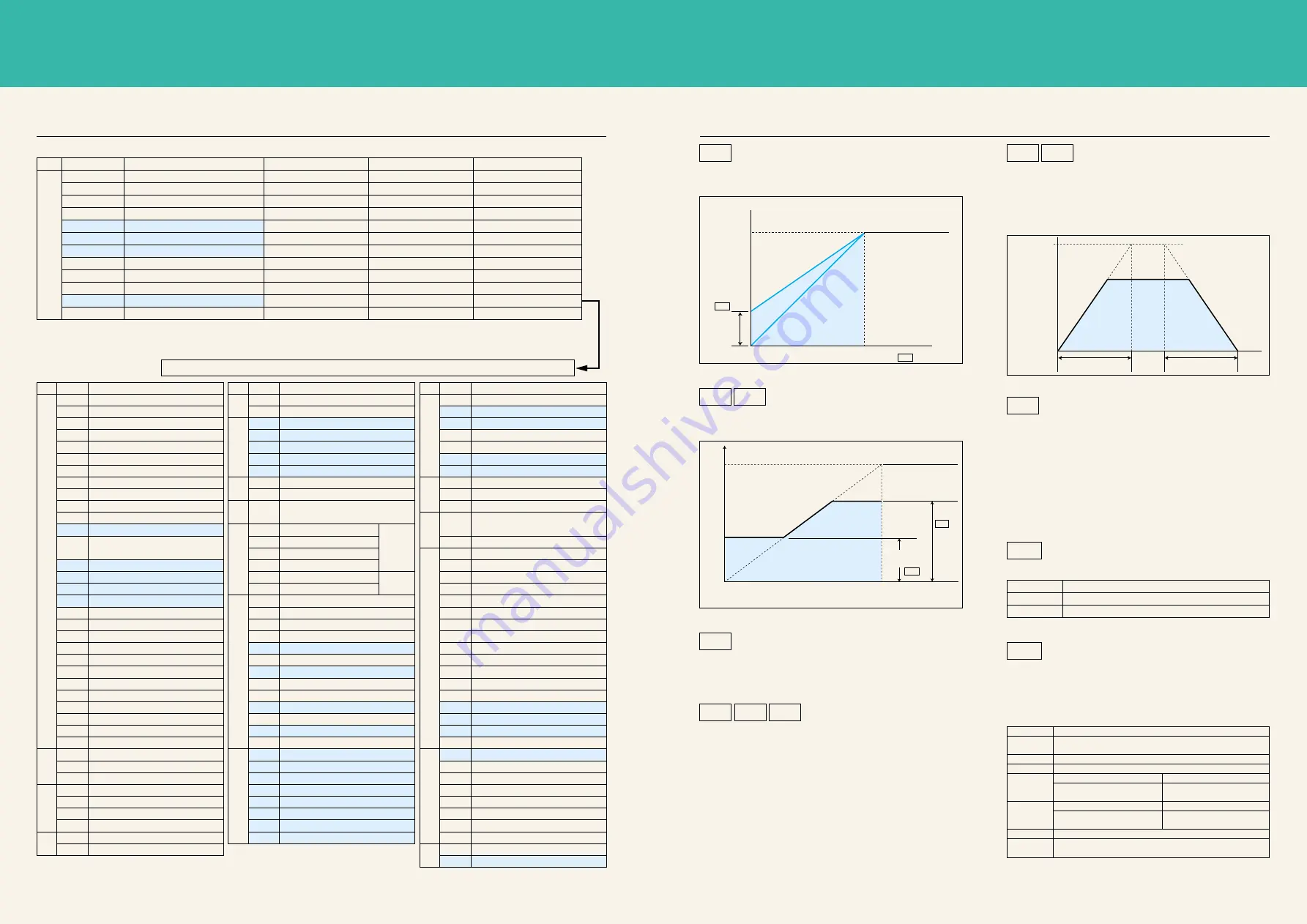

List of Parameters

Explanation of Parameters

"Pr." is the abbreviation of parameter.

Torque boost

䊏

Basic functions <default state>

䊏

Extended functions

Parameter

0

1

2

3

4

5

6

7

8

9

30

79

Torque boost

Maximum frequency

Minimum frequency

Base frequency

Multi-speed setting (high speed)

Multi-speed setting (medium speed)

Multi-speed setting (low speed)

Acceleration time

Deceleration time

Electronic thermal O/L relay

Extended function display selection

Operation mode selection

0~15%

0~120Hz

0~120Hz

0~120Hz

0~120Hz

0~120Hz

0~120Hz

0~999 s

0~999 s

0~50A

0, 1

0~4, 7, 8

0.1%

0.1Hz

0.1Hz

0.1Hz

0.1Hz

0.1Hz

0.1Hz

0.1 s

0.1 s

0.1A

1

1

6%/5%/4% (Note 4)

60Hz

0Hz

60Hz

60Hz

30Hz

10Hz

5 s

5 s

Rated output current (Note 3)

0

0

Name

Setting range

Minimum setting unit

Default setting

Function

Basic functions

Standard operation functions

Current

detection

Restart

Terminal function

selection

Operation selection functions

Multi-speed operation functions

Remote

setting

Display functions

PID control

Slip

compensation

Automatic

torque boost

Communication/PU function (Note 2)

Calibration functions

Auxiliary

functions

Output terminal

functions

2nd functions

Current

detection

1. The shaded parameters can be changed even during operation.

2. This parameter is provided only with the type having the RS-485 communication function.

3. This will be 85% of the rated output current for 0.75K or less.

4. This will be 5% for FR-S540-1.5K and 2.2K, and 4% for FR-S540-3.7K.

(Notes)

By setting parameter 30 to 1, the following extended function parameters can be set.

Parameter

Function

Name

10

11

12

13

14

15

16

17

19

20

21

22

23

24

25

26

27

28

29

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

DC injection brake operation frequency

DC injection brake operation time

DC injection brake voltage

Starting frequency

Load pattern selection

JOG frequency

JOG acceleration/deceleration time

RUN key rotation direction selection

Base frequency voltage

Acceleration/deceleration reference frequency

Stall prevention function selection

Stall prevention operation level

Stall prevention operation level

compensation factor at double speed

Multi-speed setting (speed 4)

Multi-speed setting (speed 5)

Multi-speed setting (speed 6)

Multi-speed setting (speed 7)

Stall prevention operation reduction starting frequency

Acceleration/deceleration pattern

Frequency jump 1A

Frequency jump 1B

Frequency jump 2A

Frequency jump 2B

Frequency jump 3A

Frequency jump 3B

Speed display

Frequency setting voltage gain frequency

Frequency setting current gain frequency

Start-time ground fault detection selection

Up-to-frequency sensitivity

Output frequency detection

Output frequency detection at reverse rotation

2nd acceleration/deceleration time

2nd deceleration time

2nd torque boost

2nd V/F (base frequency)

Output current detection level

Output current detection signal delay time

Parameter

Function

Name

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

80

81

82

83

84

85

86

87

Zero current detection level

Zero current detection time

Control panel display data selection

Frequency setting operation selection

FM terminal function selection

Frequency monitor reference

Current monitor reference

Restart coasting time

Restart cushion time

Remote setting function selection /

Frequency setting storage function selection

RL terminal function selection

RM terminal function selection

RH terminal function selection

STR terminal function selection

RUN terminal function selection

A, B, C terminal function selection

Retry selection

Number of retries at alarm occurrence

Retry waiting time

Retry count display erase

Soft-PWM setting

Applicable motor

PWM frequency selection

0 to 5V/0 to 10V selection

Input filter time constant

Reset selection/ PU stop selection

Cooling fan operation selection

Parameter write disable selection

Reverse rotation prevention selection

Multi-speed setting (speed 8)

Multi-speed setting (speed 9)

Multi-speed setting (speed 10)

Multi-speed setting (speed 11)

Multi-speed setting (speed 12)

Multi-speed setting (speed 13)

Multi-speed setting (speed 14)

Multi-speed setting (speed 15)

Parameter

Function

Name

88

89

90

91

92

93

94

95

96

97

98

99

n 1

n 2

n 3

n 4

n 5

n 6

n 7

n 8

n 9

n 10

n 11

n 12

n 13

n 14

n 15

n 16

n 17

c 1

c 2

c 3

c 4

c 5

c 6

c 7

c 8

CLr

ECL

PID operation selection

PID proportional band

PID integral time

PID upper limit

PID lower limit

PID control set point during PU operation

PID differential time

Motor rated slip

Slip compensation time constant

Constant output area slip compensation selection

Automatic torque boost selection

(motor capacity)

Motor primary resistance

Communication station number

Communication speed

Stop bit length

Parity check presence/absence

Number of communication retries

Communication check time interval

Wait time setting

Operation command write

Speed command write

Link start mode selection

CR/LF selection

E

2

PROM write validity selection

PU display language

PU buzzer sound control

PU contrast adjustment

PU main display screen data selection

PU dislocation detection/PU setting lock

FM terminal calibration

Frequency setting voltage bias frequency

Frequency setting voltage bias

Frequency setting voltage gain

Frequency setting current bias frequency

Frequency setting current bias

Frequency setting current gain

Parameter for manufacturer setting. Do not set.

Parameter clear

Alarm history clear

Pr.20

Pr.7

Pr.8

Acceleration time Deceleration time

100%

Frequency setting signal

5V

(10V)

(20mA)

Maximum

frequency

Minimum

frequency

Pr.1

Pr.2

100%

Setting

range

Output frequency

Output voltage

Output frequency

Output frequency

Base frequency

Pr.0

Pr.3

Pr.0

●

The motor torque in the low frequency area

can be adjusted according to the load.

Pr.7

Acceleration/deceleration time

Pr.8

●

For the acceleration time, set the time to reach

the acceleration/deceleration reference frequency

Pr. 20 (default value: 60Hz) from 0Hz,

and for the deceleration time, set the time to reach

0Hz from Pr. 20 (default value: 60Hz).

Electronic thermal O/L relay

Pr.9

●

The setting value to protect the motor from

overheating can be set as a current value.

Normally, the motor rated current is set for 50Hz.

●

When 0A is set, the motor protective function

will not activate. (The inverter output transistor's

protective function will activate.)

●

When connecting multiple motors, set an external

thermal relay for each motor.

Extended function display selection

Pr.30

●

Set this to display and set the extended function parameters.

Operation mode selection

Pr.79

●

The inverter operation modes include operation

with external signal and operation with the PU

(setting dial, touch keys). The mode can be fixed

to one mode, or two modes can be used together.

Pr.1

Maximum/minimum frequency

Pr.2

Base frequency

Pr.3

●

The upper limit and lower limit of the output

frequency is clamped.

●

Set the base frequency (reference frequency for motor

rated torque) between 0 and 120Hz according to the motor.

Pr.4 Pr.5

Multi-speed setting

Pr.6

●

Various speeds (RH, RM, RL) can be selected

just by changing the contact signal from an

external source.

●

Each speed (frequency) can be set

between 0 and 120Hz while the inverter is running.

Setting value

0

1

Setting value

0

1

2

3

4

7

8

Details

Display only basic functions

Display all parameters

Details

Operation is possible by changing between PU

(setting dial, touch key) operation or external operation.

Operation frequency

Setting with setting dial

· Multi-speed selection

· 4 to 20mADC input

External terminal (STF/STR)

External terminal signal

(Multi-speed, 0 to 5VDC, etc.)

RUN key

PU operation interlock

Operation mode external signal changeover

Select operation mode by turning PU operation/external operation

mode changeover (X16) signal ON and OFF.

Starting signal

Operation frequency

Starting signal

Operation is possible only with PU (setting dial, touch key) operation.

Only external operation is possible.

*

Refer to the Instruction Manual for details.

Can be selected with

the RL, RM, RH, RT,

AU, STOP, MRS, OH,

REX, JOG, RES, X14,

X16 and STR signals.

(The STR signal can

be assigned only

with Pr. 63.)

Can be selected with the

RUN, SU, OL, FU, RY,

Y12, Y13, FDN, FUP, RL,

LF and ABC signals.

6

7