Power-OFF and magnetic contactor (MC)

PRECAUTIONS FOR USE OF THE INVERTER

77

3

3.4

Power-OFF and magnetic contactor (MC)

Inverter input side magnetic contactor (MC)

On the inverter input side, it is recommended to provide an MC for the following purposes:

(Refer to

for selection.)

• To disconnect the inverter from the power supply at activation of a protective function or at malfunctioning of the driving

system (emergency stop, etc.). For example, an MC prevents overheat or burnout of the brake resistor when heat capacity

of the resistor is insufficient or brake regenerative transistor is damaged with short while connecting an optional brake

resistor.

• To prevent any accident due to an automatic restart at power restoration after an inverter stop made by a power failure.

• To separate the inverter from the power supply to ensure safe maintenance and inspection work.

If using an MC for emergency stop during motor driving, select an MC regarding the inverter input side current as JEM1038-

AC-3 class rated current.

NOTE

• Since repeated inrush currents at power ON will shorten the life of the converter circuit (switching life is about 1,000,000

times), frequent starts and stops of the magnetic contactor must be avoided. Turn ON/OFF the inverter start controlling

terminals (STF, STR) to run/stop the inverter.

Handling of the magnetic contactor on the inverter's output side

Switch the magnetic contactor between the inverter and motor only when both the inverter and motor are at a stop. When the

magnetic contactor is turned ON while the inverter is operating, overcurrent protection of the inverter and such will activate.

When an MC is provided to switch to a commercial power supply, for example, it is recommended to use the commercial

power supply-inverter switchover function

Pr.135 to Pr.139

(Refer to the FR-F800 Instruction Manual (Detailed)). (The

commercial power supply operation is not available with PM motors.)

Handling of the manual contactor on the inverter's output side

A PM motor is a synchronous motor with high-performance magnets embedded inside. High-voltage is generated at the motor

terminals while the motor is running even after the inverter power is turned OFF. In an application where the PM motor is

driven by the load even after the inverter is powered OFF, a low-voltage manual contactor must be connected at the inverter's

output side.

NOTE

• Before wiring or inspection for a PM motor, confirm that the PM motor is stopped. In an application, such as fan and blower,

where the motor is driven by the load, a low-voltage manual contactor must be connected at the inverter's output side, and

wiring and inspection must be performed while the contactor is open. Otherwise you may get an electric shock.

• Do not open or close the contactor while the inverter is running (outputting).

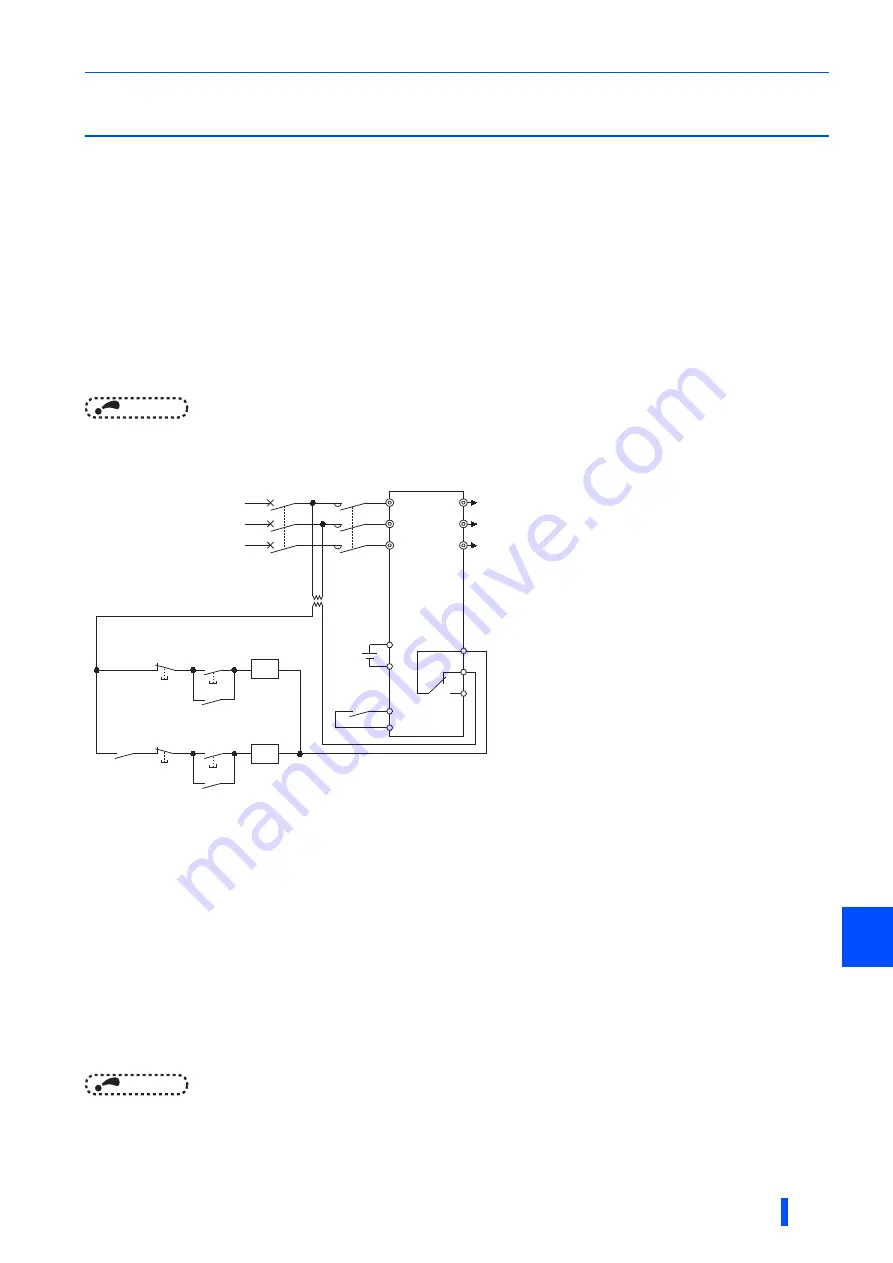

• Inverter start/stop circuit example

As shown on the left, always use the start

signal (ON or OFF of STF(STR) signal) to

make a start or stop.

Install a stepdown transformer.

To hold an alarm signal when the inverter's

protection circuit is activated, input a 24 V

external power supply across ter24

and SD. (Refer to

Power

supply

MCCB

RA

U

V

A1

B1

C1

W

To the

motor

Inverter

SD

MC

STF/STR

R/L1

S/L2

T/L3

+24

SD

OFF

ON

MC

Stop

Start

RA

MC

Operation preparation

Start/Stop

RA

MC

24 V

External

power

supply

T

∗1

∗2