Chapter 3 Precautions for Use

3–3

3-1-2 Oil and waterproofing measures

The HC motor satisfies the IEC Standards IP65 (dust prevention jet flow type) protection format as a

single motor unit.

(Reference)

IP65 test details

(1) Protect in respect to external solids

IP6

□

: Dust-proof type, and dust cannot enter.

(2) Protection in respect to entry of water IP

□

5 : Protection from jet flows in all directions. Water

is flowed in all directions from a distance of 3m.

(Flow rate 12.5 liters/min., pressure 30kPa, time

3 minutes)

Note that the following caution is required during actual use.

1)

These standards are the short-time performance standards, and do

not guarantee continuous environment protection characteristics. If

the motor could be in constant contact with oil or water, and the matter

could enter, always provide a cover, etc. Note that the IP class does

not indicate the corrosion resistance level.

2)

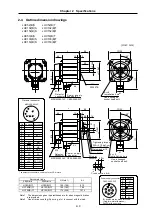

When a gear box is installed on the servomotor, make sure that the oil level height from the center

of the shaft is higher than the values given below. Open a breathing hole on the gear box so that the

inner pressure does not rise.

Servomotor

Oil level (mm)

HC52, 102, 152

HC53, 103, 153

20

HC202, 352, 452, 702

HC203, 353, 453, 703

25

HC902

30

HC103R, 153R, 203R

HC353R, 503R

20

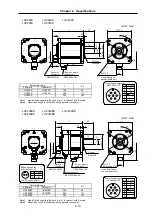

3) When installing the servomotor horizontally, set the power supply cable and detector cable to face

downward.

When installing vertically or on an inclination, provide a cable trap.

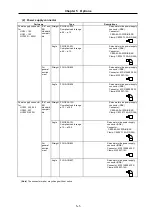

CAUTION

1. The servomotors, including those having IP65 and IP67 specifications, do not

have a waterproof (oil-proof) structure. Do not allow the machine to be

constantly wetted or submerged in water or oil, and make sure that these

substances do not enter the motor. Note that accumulation of cutting chips

will also cause oil to seep into the motor.

2. When the motor is installed facing upwards, take measures on the machine

side so that the gear oil does not flow onto the motor shaft, etc.

3. Do not remove the detector from the HC motor. (The detector installation

screw is treated for sealing.)

Servomotor

Gear

Lip

Oil level

V-ring

Oil or water

Servomotor

Cable

trap