5

4. Installing the pipes

4.1. Refrigerant and drainage piping locations of indoor

unit

The figure marked with * in the drawing represent the dimensions of the main unit

excluding those of the optional multi function casement. (Fig. 4-1)

A

Drain pipe

B

Ceiling

C

Grille

D

Refrigerant pipe (liquid)

E

Refrigerant pipe (gas)

F

Water supply inlet

G

Main unit

• When the optional multi-functional casement is installed, add 135 mm to the di-

mensions marked on the figure.

(mm)

Models

A

RP3

80

RP4, 5, 6

84

16

89

A

98

G

A

∗

170

∗

140

∗

190

60

286

374

A

F

D

E

B

C

Fig. 4-1

5. Refrigerant piping work

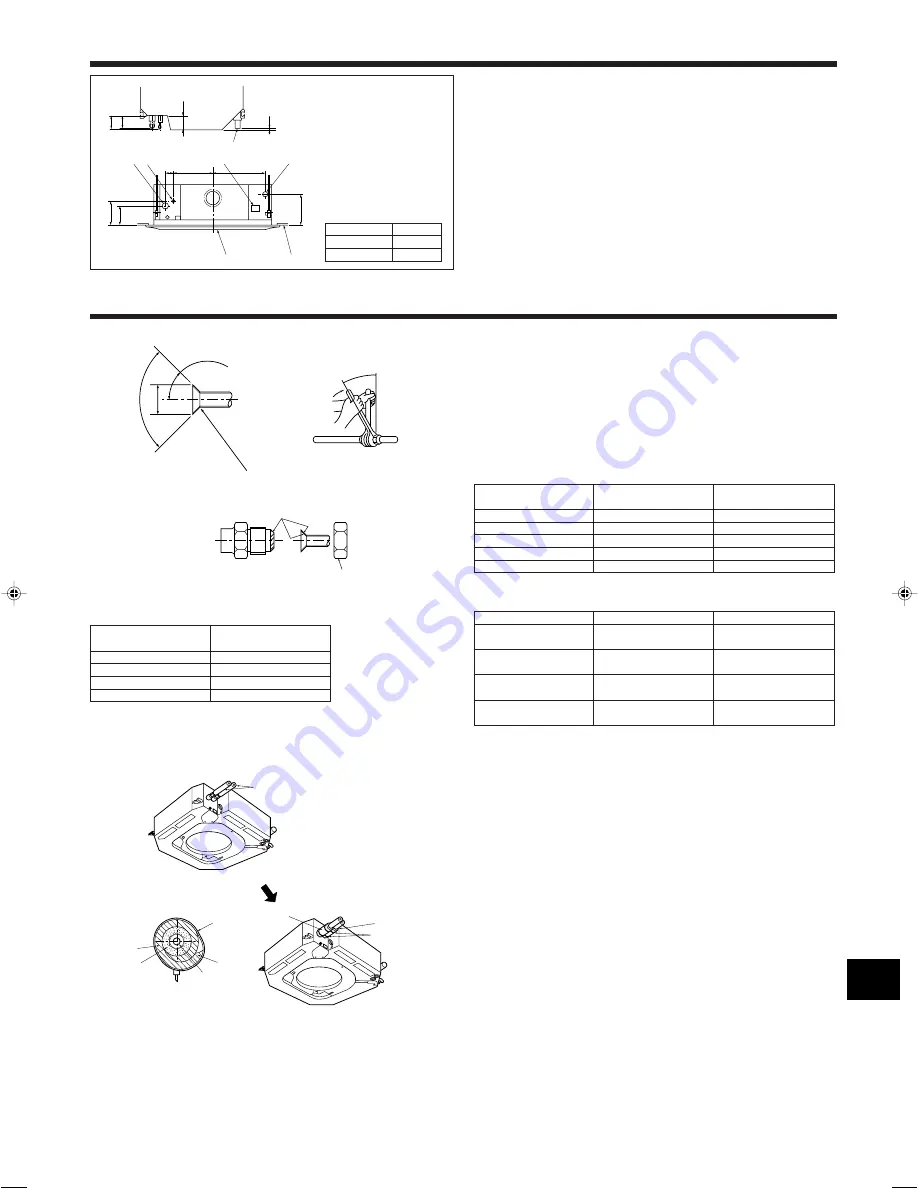

5.1. Connecting pipes (Fig. 5-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C or more,

thickness of 12 mm or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam insu-

lation materials (specific gravity of 0.03, thickness of 9 mm or more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tightening

flare nut.

• Use two wrenches to tighten piping connections.

• Use refrigerant piping insulation provided to insulate indoor unit connections. Insu-

late carefully.

A

Flare cutting dimensions

Copper pipe O.D.

Flare dimensions

(mm)

øA dimensions (mm)

ø6.35

8.7 - 9.1

ø9.52

12.8 - 13.2

ø12.7

16.2 - 16.6

ø15.88

19.3 - 19.7

B

Flare nut tightening torque

Copper pipe O.D.

Flare nut O.D.

Tightening torque

(mm)

(mm)

(N·m)

ø6.35

17

14 - 18

ø9.52

22

34 - 42

ø12.7

26

49 - 61

ø15.88

29

68 - 82

ø15.88

36

100 - 120

Indoor unit (Liquid)

Indoor unit (Gas)

Outdoor unit (Liquid)

Outdoor unit (Gas)

RP3

Flare nut attached to

indoor liquid valve

Flare nut attached to

indoor gas valve

Flare nut attached to

outdoor liquid valve

Flare nut attached to

outdoor gas valve

RP4-6

Flare nut attached to

indoor liquid valve

* Flare nut in outdoor

unit accessories

Flare nut attached to

outdoor liquid valve

Flare nut attached to

outdoor gas valve

* In case that the flare nut attached to indoor gas valve is used, gas leakage or even

pipe extraction will occur.

90

°

±

0.5

°

ø

A

R0.4~R0.8

A

45

°±

2

°

B

C

D

Fig. 5-1

B

D

E

A

C

F

J

H

I

B

,

C

F

G

Fig. 5-2

A

Refrigerant pipe and insulating ma-

terial

B

Pipe cover (large)

C

Pipe cover (small)

D

Refrigerant pipe (gas)

E

Refrigerant pipe (liquid)

F

Band

G

Cross-sectional view of connection

H

Pipe

I

Insulating material

J

Squeeze

C

Apply refrigerating machine oil over the entire flare seat surface.

D

Use the flare nuts as follows.

5.2. Indoor unit (Fig. 5-2)

Heat insulation for refrigerant pipes:

1

Wrap the enclosed large-sized pipe cover around the gas pipe, making sure that

the end of the pipe cover touches the side of the unit.

2

Wrap the enclosed small-sized pipe cover around the liquid pipe, making sure

that the end of the pipe cover touches the side of the unit.

3

Secure both ends of each pipe cover with the enclosed bands. (Attach the bands

20 mm from the ends of the pipe cover.)

• After connecting the refrigerant piping to the indoor unit, be sure to test the pipe

connections for gas leakage with nitrogen gas. (Check that there is no refrigerant

leakage from the refrigerant piping to the indoor unit.)

5.3. For twin/triple combination

Refer to the outdoor unit installation manual.