2-25

Options

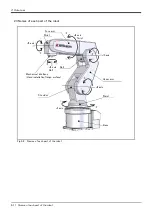

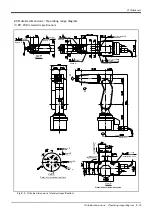

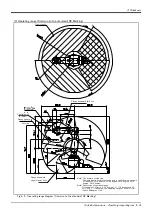

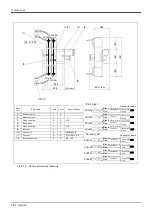

2 Robot arm

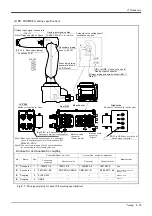

■ Cable configuration

The configuration of the flexible cable is shown in

. Refer to this table when selecting the cable bare.

Table 2-6 : Cable configuration

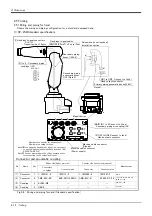

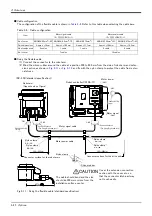

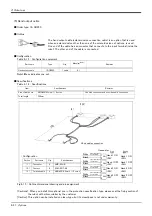

■ Fixing the flexible cable

(1) Connect the connector to the robot arm .

(2) Wind the silicon rubber around the cable at a position 300 to 400 mm from the side of robot arm and exten

-

sion section as shown in

, and fix with the nylon clamp to protect the cable from exter

-

nal stress.

Fig.2-11 : Fixing the flexible cable (standard specification)

Item

Motor signal cable

1S- □□ LCBL(S)-11

Motor power cable

1D- □□ LCBL(P)-11

No. of cores

AWG#24(0.2mm

2

)-4P

AWG#24(0.2mm

2

)-7P

AWG#18(0.75mm

2

)

AWG#16(1.25mm

2

)-4C

AWG#18(0.75mm

2

)-4C

Finish dimensions

Approx. φ6mm

Approx. φ8.5mm

Approx. φ1.7mm

Approx. φ8.9mm

Approx. φ6.5mm

No.of cables used

5 cables

1 cable

1 cable

2 cable

8 cable

No. in total

7 cables

10 cables

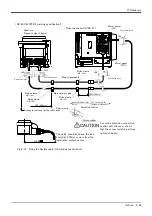

CN1

CN2

ロボット本体

(ベース部背面)

コントローラ (背面)

モータパワー

モータ信号

(CN2)

モータ信号ケーブル

モータパワーケーブル

(CN1)

CN2

CN1

接続リング部

(固定)

接続リング部

(固定)

ラッチ

(固定用 左右)

ラッチ

(固定用 左右)

ナイロンクランプ

NK-18N

ナイロンクランプ

NK-14N

シリコンゴム

ナイロンクランプ

300~400mm

ロボット本体コネクタ面

ドライブユニットコネクタ面

300~400mm

ナイロンクランプ

NK-18N

ナイロンクランプ

NK-14N

Robot controller CR1DA-771

Motor power cable

Nylon clamp

Nylon clamp

Nylon clamp

Nylon clamp

Nylon clamp

Silicon rubber

Motor power

Motor signal

Robot arm

(Opposite side of figure)

Connection ring

(fixing)

Connection latch

(For fixing. Right and left )

Connection latch

(For fixing. Right and left )

Motor signal cable

Connection ring

(fixing)

Connector surface for the robot arms

Connector surface for the drive unit

<RV-2SD(standard specification)>

The cable should bend and the size

should be 300mm or more from the

installation surface center.

min

CAUTION

Cover the extension connection

section with the cover etc. so

that the connector latch part may

not touch easily.