34

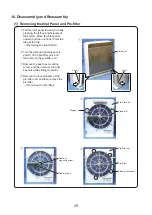

(8) Removing and Replacing the Fan and Blower Motor

1

Remove the power supply control

circuit board.

→ (See “(4

) Removing and Replacing

the Power Supply Circuit Board”.)

2

Remove the nut, washer B, and fan

spacer, and then remove the fan and

washer A.

→ (Removing and Replacing the Fan)

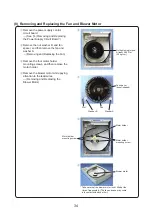

3

Remove the four motor holder

mounting screws, and then remove the

motor holder.

4

Remove the blower motor while paying

attention to the lead wires.

→ (Removing and Replacing the

Blower Motor)

Nut tightening torque:

At least 2.94 N

•

m

(30 kgf

•

cm)

2

2

Nut

Washer B

Washer A

Fan spacer

(donut-shaped)

Fan

3

Motor holder

Motor holder

mounting screw

Motor holder

mounting screw

4

Blower motor

* Take care that the blower motor is not tilted at the

time of reassembly. (The fan and case may come

into contact with each other.)