3

)

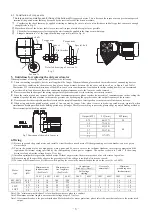

Brake specifications

Table 5 shows the standard specifications for the brake.

Table 5 Standard Specifications for Brake

Brake

model

Output

(kW)

Number

of poles

(P)

Brake power

supply

Voltage(V)

Braking

voltage

DC(V)

Braking

Current

(A)

Braking torque

(Nm)

*Note 1 and

2

Gap(mm) Lining

thickness

Initial gap

Limit

gap

Initial

thickness

Limit

thickness

SNB 0.8

0.75

4

200

90

0.24 7.16

0.15(inserted)-0.25 (not inserted)

0.5 7.7 6.7

SNB1.5 1.5

200

0.25 14.3

0.20(inserted)-0.30 (not inserted)

0.5 10.0 8.5

SNB2 2.2

200

0.37 21.0

0.20(inserted)-0.30 (not inserted)

0.5 10.0 8.5

Note

1: The braking torque values shown in the above table are the static friction torque values. Dynamic friction torque values will be

approximately 80% of the static friction torque values.

Note2:

At starting first operation or after replacing the brake lining, the braking torque may be less than the specified torque. In this case, fit the

friction surfaces of the brake by applying the brake several times with a light load

4

)

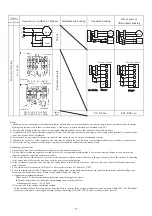

Rectifier specifications

Table6 shows the standard specifications for the rectifier .

Table6 Standard specifications for Rectifier

Output

(kW)

Power supply

voltage (V)

Output voltage

DC(V)

Control method

Rating

Ambient temperature and

humidity

Installation

0.75

~

2.2

200 90

Half wave

rectification method

Continuous

-15

~

+40°C

90%RH or less

On terminal block

.

5

)

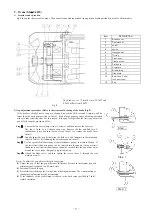

Manual brake releasing procedure

a)

Simplified manual brake releasing

For this brake releasing method, prepare the brake release bolts shown in Table 7

Step

1

Loosen the fan cover clamp screws (4 screws), and then remove the fan cover. After

that, remove the fan and End-face V seal(outdoor type). (The fan is fixed by hexagon

socket head setscrews.)

Step

2

Loosen the screws (item 3), and then remove the brake cover (item 1). Screw the machine

screws into the threaded holes of the side plate. The machine screws will push the

Armature to release the brake. At the completion of manual brake releasing, be sure to

reset the brake.

Table 7 Simplified manual brake release bolt

Brake model

Simplified manual brake release bolt

SNB0.8 M4×25

SNB1.5

M6

x

40

SNB2

b

)

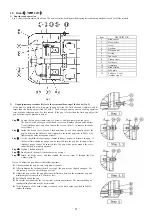

One-touch manual brake releasing (optional)

The written contents of one-touch manual brake releasing(optional) are the same as that of 0.1

~

0.4kW.

Please refer to P9

Notes: To manually release the brake, observe the following items:

Be sure to check that the brake is properly released.

Basically, reducing the gap to zero will release the brake. To check whether the brake is released,

manually turn the motor shaft. If you can turn the shaft, judge that the brake is released.

If a large tightening force is applied to the simplified manual brake release bolt, the Armature or

side plate may be distorted or damaged, and normal operation may not be possible. For this reason,

carefully tighten the manual release bolt.

If the manually released brake is not reset, do not operate the motor. Before starting full-scale

operation, be sure to check that the brake functions properly.

For simplified manual brake releasing, up to 50 times of releasing is allowable.

a)Simplified manual brake

releasing(pattern 1)

b)Simplified manual brake

releasing(pattern 2)

- 12 -

Summary of Contents for GM-SHY

Page 1: ......

Page 2: ......

Page 20: ... 18 ...

Page 21: ... 19 ...

Page 22: ... 20 ...

Page 23: ......

Page 24: ......