3

)

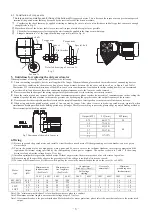

Brake specifications

Table3 shows the standard specifications for the brake.

Table 3 Standard Specifications for Brake

Brake

model

Output

(kW)

Number

of poles

(P)

Brake power

supply

Voltage(V)

Braking

voltage

DC(V)

Braking

Current

(A)

Braking torque

(Nm)

*Note 1 and 2

Gap(mm)

Lining thickness

Initial gap

Limit

gap

Initial

thickness

Limit

thickness

SBM 80

0.1,0.2

4

200

90

0.16

1.91

0.15(inserted)-0.25 (not inserted)

0.4 6.0 5.3

SNB 0.4

0.4

4

200

90

0.18

3.82

0.15(inserted)-0.25 (not inserted)

0.4 5.9 4.9

Note

1: The braking torque values shown in the above table are the static friction torque values. Dynamic friction torque values will be

approximately 80% of the static friction torque values.

Note 2: At starting first operation or after replacing the brake lining, the braking torque may be less than the specified torque. In this case, fit the

friction surfaces of the brake by applying the brake several times with a light load

4

)

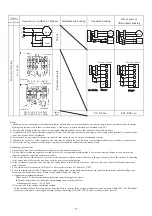

Rectifier specifications

Table 4 shows the standard specifications for the rectifier (for the 200V type).

Table 4 Standard specifications for Rectifier

Output

(kW)

Power supply

voltage (V)

Output voltage

DC(V)

Control method

Rating

Ambient temperature

and humidity

Installation

0.1,0.2 200

90

Half wave

rectification method

Continuous

-15

~

+40°C

90%RH or less

On terminal block

0.4 200

90

5

)

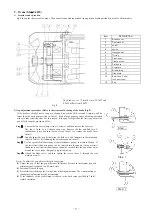

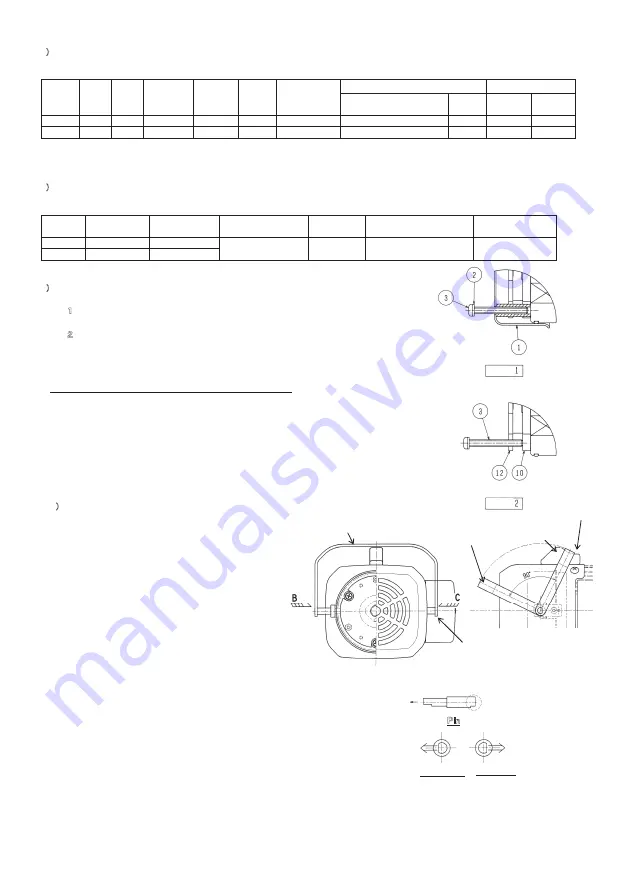

Manual brake releasing procedure

a)

Simplified manual brake releasing

Step

1

Loosen the fan cover clamp screws (4 screws), and then remove the fan cover. After that,

remove the fan and End-face V seal.(outdoor type)

;

The fan is fixed by a C-shaped snap ring.

Step

2

Loosen the screws (item 3), and then remove the brake cover (item 1). Screw the machine

screws into the threaded holes of the side plate. The machine screws will push the Armature

to release the brake. At the completion of manual brake releasing, be sure to reset the brake.

Notes: To manually release the brake, observe the following items:

Be sure to check that the brake is properly released.

Basically, reducing the gap to zero will release the brake. To check whether the brake is released,

manually turn the motor shaft. If you can turn the shaft, judge that the brake is released.

If a large tightening force is applied to the simplified manual brake release bolt, the Armature or

side plate may be distorted or damaged, and normal operation may not be possible. For this reason,

carefully tighten the manual release bolt.

If the manually released brake is not reset, do not operate the motor. Before starting full-scale

operation, be sure to check that the brake functions properly.

For simplified manual brake releasing, up to 50 times of releasing is allowable.

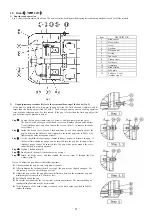

b

)

One-touch manual brake releasing (optional)

・

On the top of the fan cover, there is a brake release lever.

Turn the lever 90°to release the brake. (Do not turn the lever

more than 90°. The brake may not be released.) At the

completion of manual brake releasing, be sure to return the

lever to the initial position.

・

.For one-touch manual brake releasing, up to 100 times of

releasing is allowable.

The gap adjustment (maintenance) point of one-touch

manual brake releasing

【

The resolution point at the time of the gap adjustment

】

①

Open a manual lever and exclude combination with the

pin of right and left.

②

Each right and left pulls up pin.

③

Please refer to the gap adjustment point for the following

work.

【

The point to reassemble after the maintenance

】

①

Confirm it so that a D cut parallelism department of the

manual lever combination department turns to the slowdown

machine side and insert it from a fan cover hole.

②

Open a manual lever and combined with the pin of right and left.

※

Attention

Of the manual lever please be careful to be able to spread too much.

A wobble occurs in the combination with the pin when I open too much it,

and a manual lever is easy to come to come off.

Step

Step

initial position

Position of manual lever releasing

Manual lever

Lever fixation

pin

(

Both side

)

Pin

View of B

View of C

side of Reduction

side of Reduction

Insert direction

Connection of manual

lever

- 10 -

Summary of Contents for GM-SHY

Page 1: ......

Page 2: ......

Page 20: ... 18 ...

Page 21: ... 19 ...

Page 22: ... 20 ...

Page 23: ......

Page 24: ......