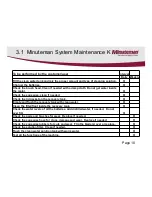

3. Maintenance Intervals

•

Maintenance Intervals:

In a modular structure, the Minuteman System Maintenance determines the specific

technical proceedures to be preformed and sets the time interval between the two

maintenance cycles.

For each of the maintenance cycle, the replaceable parts are determined as well.

Further details described in the specific chapters.

•

Minuteman System Maintenance K:

To be performed by the customer (in daily or weekly intervals) according to the maintenance

and care instructions as specified in the operating instructions.

The operator must be professionally instructed after delivery of the machine by selling

dealer.

•

Minuteman System Maintenance I:

(after every 125 hours of operation)

To be preformed an authorized Minuteman Service Center in accordance with the machine-

specific system maintenance.

•

Minuteman System Maintenance II:

(after every 250 hours of operation)

To be preformed an authorized Minuteman Service Center in accordance with the machine-

specific system maintenance.

•

Minuteman System Maintenance S:

(after every 500 hours of operation, safety check) To

be performed by an authorized Minuteman Service Center in accordance with the machine-

specific system maintenance.

Page 9

Summary of Contents for E17BD

Page 6: ...2 Technical Specifications E17BD E20 Page 6 ...

Page 7: ...2 1 Dimensions E17BD E20 BD With a Straight Squeegee Page 7 ...

Page 8: ...2 2 Dimensions E17 E20 With Curved Squeegee Page 8 ...

Page 11: ...3 2 Minuteman System Maintenance I Page 11 ...

Page 12: ...3 3 Minuteman System Maintenance II Page 12 ...

Page 13: ...3 4 Minuteman System Maintenance S Page 13 ...

Page 39: ...11 Squeegee Curved 11 Page 39 ...

Page 40: ...11 Squeegee Curved 11 1 Page 40 ...

Page 52: ...17 1 Solution Filter Version 1 17 1 Page 52 ...

Page 64: ...20 Notes Page 64 ...