CONTENTS

FOR INSTALLATION ......................................................................................

A- 1

A-l

.............................................................................................

A-l

A-l

A- 1

A-l

A-2

1. SPECIFICATIONS ......................................................................................................................

B-l

B-3

B-4

B-5

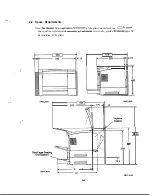

LAYOUT ..................................................................................

B-6

LAYOUT ........................................ ..................................................................

B-7

.......................................................

........... B-8

SERVICE PARTS ON P. W. BOARDS .............................................................. B-9

B-10

B-10

................................................................

.......................................... B-11

B-12

B-13

vi

Summary of Contents for 2060

Page 1: ......

Page 2: ......

Page 3: ...S P A 3 1 0 Service Parts Manual September 1996 Revision C 02 ...

Page 4: ......

Page 5: ...WARNING LABELS i ...

Page 31: ... I PRINTING PROCESS I 9 Paper Exit Duplex I Sensor C l ...

Page 51: ...E ADJUSTMENT 1 IMAGE REGISTRATION E 1 ...

Page 52: ... ...

Page 57: ......

Page 61: ......

Page 64: ... 0993 PARTS MANUAL MINOLTA QMS ...

Page 68: ...L H O U S I N G 9C 3 PARTS MANUAL ...

Page 70: ...FRAMES 7 L J P PARTS MANUAL ...

Page 72: ...1 PARTS MANUAL1 5 ...

Page 76: ......

Page 78: ...T R A N S P O R T SFCTION 2 9 E PARTS MANUAL L ...

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ...0 a P A R T S M A N U A L ...

Page 86: ... 4 ...

Page 87: ... ...

Page 88: ......

Page 92: ......

Page 93: ... ...

Page 94: ......