Service and Repair Manual

Model 840S

4

%

%

%

%

%

SEE PAGE 5

FOR ADDITIONAL

LUBRICATION

AND SERVICE NOTES

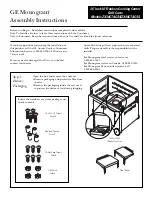

NOTE:

Do not wash

clutch gear assembly (57).

If needed, wipe off with a

dry rag.

Coat gearcase seal (62) with lubrication

prior to placement in the gearcase (38).

Use Blue

Loctite

#242 on

screws

(24), two

places.

_____________________________________________________________________________________________________________________________

______________________________________________________________

________________________________________________________________

_______________________________________________________________

______________________________________________________________

______________________________________________________________

________________________________________________________________

___________________________________________

___________________________________________

____________________________________________

___________________________________________

___________________________________________

___________________________________________

___________________________________________

___________________________________________

___________________________________________

FASTENER TORQUE SPECIFICATIONS (IN.LBS.)

SEATING TORQUE

FIG. NO.

MINIMUM

MAXIMUM

9

120

140

10

20

25

11

3

6

12

4

8

13

20

25

14

20

25

15

20

25

16

50

55

17

30

35

22

30

35

23

15

20

24

20

25

25

50

55

26

15

20

74

130 FT. LBS.

200 FT. LBS.

87

130 FT. LBS.

200 FT. LBS.

Switch Screws

4

6

SERVICE GREASE-

"S2" Grease, 7 oz. tube

No. 9170 4664 70

SERVICE CARRYING CASE

No. 9170 4669 30

9170 4653 80 CARBON BRUSH SERVICE KIT

THIS KIT CONTAINS:

2

---------------

Carbon Brush

9170 4672 00 HAMMER SERVICE KIT

THIS KIT CONTAINS:

2

9170 4655 10

Cap Plug

1

9170 4657 40

Gearcase Seal

2

9170 3255 50

O-Ring

1

9170 4657 70

Cap Seal

1

9170 4658 00

O-Ring

1

9170 4658 20

O-Ring

1

9170 4673 00

O-Ring

1

9170 4658 30

Damping Washer

1

9170 4673 20

Bearing Cup

2

9170 4663 20

Split Sleeve

1

9170 4672 10

Carbon Brush

1

9170 4672 20

Carbon Brush

1

9170 4664 70

"S2" Grease - 7 oz. Tube