6.

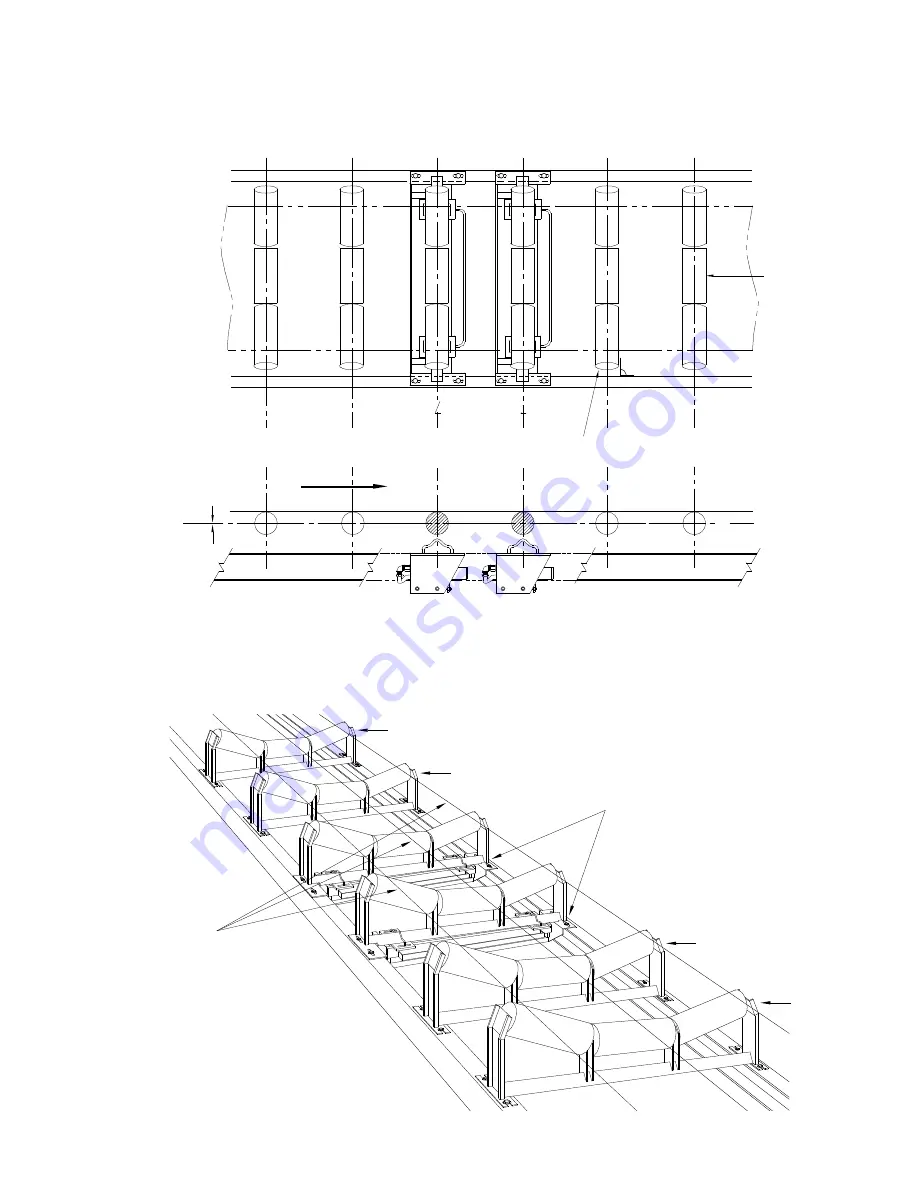

The idlers in the weighing area must be properly aligned and leveled by shimming the scale idler (S#), the

two approach (A#) and the two retreat idlers (R#) until they are within

±

0.8 mm (1/32") of each other.

Be sure to check that the idlers are centered and squared to the conveyor during the shimming process.

7.

Precise idler alignment is very important if maximum accuracy of the weighing system is to be achieved.

Misaligned idlers will result in unequal forces being applied on each idler in the weighing area, causing

calibration and measurement errors. Use a good quality wire or string to check for alignment. The wire

or string must be able to withstand sufficient tension as to eliminate any sag. By shimming, make the

necessary adjustments to bring all the rolls of the A2 through to the R2 idlers in line within 0.8 mm(1/32").

S 2

MSI with modified scale idler

R 1

wire or string

(for alignment)

approach idlers

retreat idlers

R 2

A 2

S 1

A 1

C

C

idlers must be square to stringers

alignment of idlers

A 2 to R 2 to be within

±

0.8 mm (1/32")

material flow

Center of

idlers to

be in line

R 2

S 1

R 1

A 2

90°

S 2

A 1

PL-327

7