20

TS571W Installation Instructions

TS571W Installation Instructions

21

WARNING:

Changes, modifications or adjustments not expressly approved by Nortek Security and Control, LLC could void the user’s

authority to operate this equipment. There Are No User Serviceable Parts.

OPERATOR LIMIT SETTING

Setting the Operator's Extended Limit:

1. Press and hold the (UP Arrow) and (

) buttons until LED1 turns on and the buzzer sounds. Release.

2. Use the (UP Arrow) and (DOWN arrow) buttons to jog the gate operator to the EXTENDED position.

3. Once you have positioned the gate operator to the EXTENDED position, press and release the (

) button to set the

EXTENDED limit.

Note:

For Pull-to-Open installations, the extended limit is the closed position for the gate. For Push-to-Open installations, the

extended limit is the open position for the gate.

Dual Sense Stall Force Setting

Do not use the Dual Sense Stall Force adjustment to compensate for a gate that is sticking or binding. Excessive Stall force may

cause damage to the gate operator or gate system.

The Stall Force adjustment controls the amount of force the opener will apply against an obstruction before it stops and reverses

direction. The controller includes three Stall Force settings, and is preset from the factory to Low. If your operator stops and

reverses during a normal cycle, follow the instructions below to change the Stall Force setting.

Adjusting the Stall Force:

1. Press and hold the (UP Arrow) and (DOWN arrow) buttons until the buzzer sounds (approximately 2 seconds). Release.

2. Use the (UP arrow) or (DOWN arrow) to adjust the Stall Force setting. LED1, 2, & 3 are used to indicate the setting. LED3 ON

indicates LOW, LED3 & 2 ON indicates MEDIUM, and LED1, 2 & 3 ON indicates HIGH.

3. Press and release the (

) button to set the Stall Force setting.

S2

S4

S3

LED1

LED2

LED3

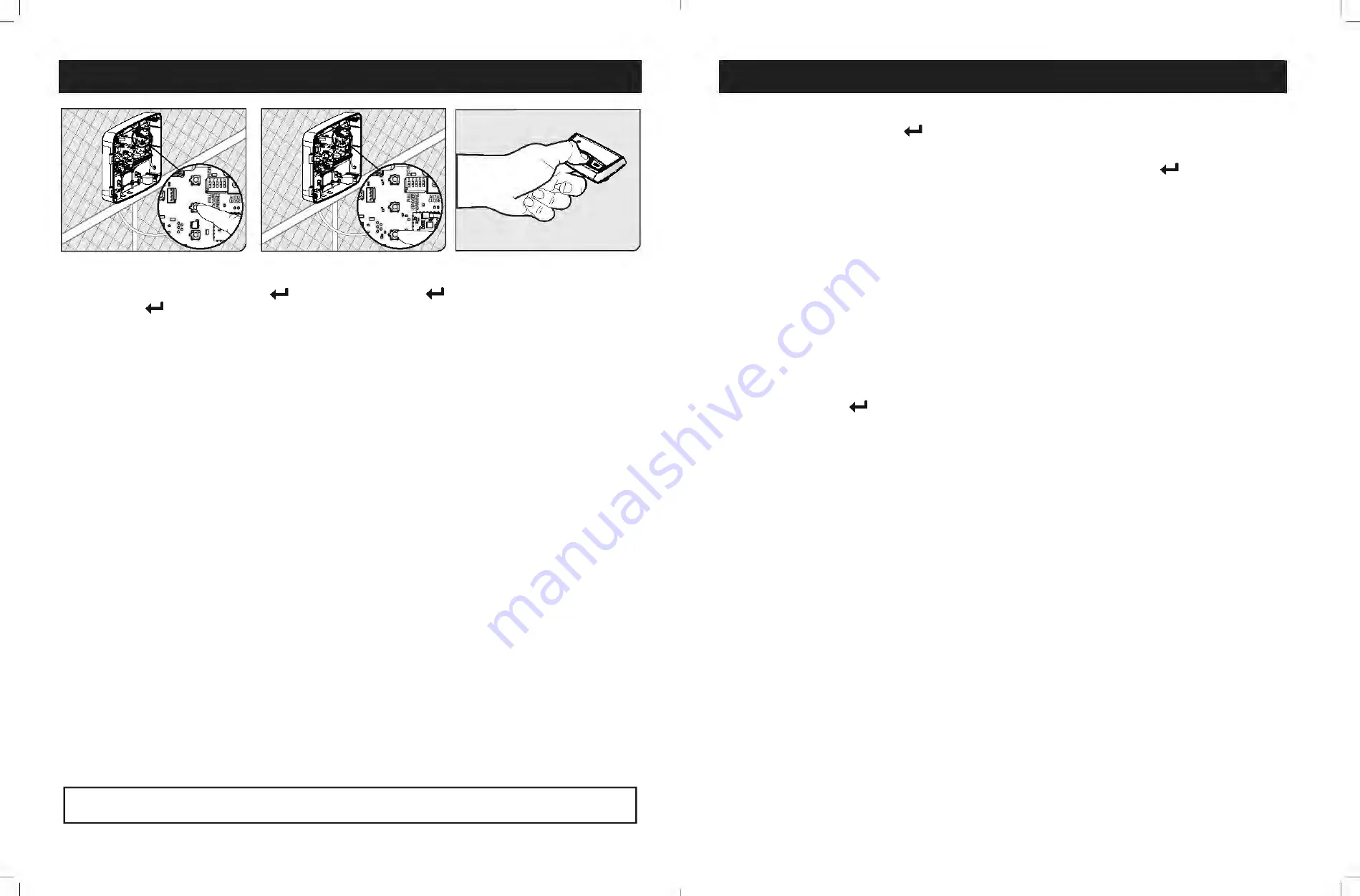

TRANSMITTER PROGRAMMING

S2

S4

S3

LED1

LED2

LED3

How to Learn a Transmitter:

1. On the control board, press and hold the (

) button until LED2 beside the (

) button turns on and the buzzer sounds.

Release the (

) button.

2. Press and hold the desired transmitter button. Once learned, LED2 will flash and the buzzer will sound indicating that the

transmitter has been learned.

How to Erase a Transmitter or Keypad (MMK200) code:

Repeat steps 1-2 above to erase the learned transmitter or keypad code.

How to Erase ALL Learned Transmitters or Keypad codes:

1. Enter the 'Learn Transmitter' mode following step 1 above.

2. Press and hold the (DOWN arrow) button until LED1, 2 & 3 flash and the buzzer sounds. (Approximately 10 seconds.)

Note:

The control board can store a total of 50 transmitter and/or keypad codes. The system is compatible with Mighty Mule DIP

switch transmitters and keypads.