32801002001 Specifications subject to change without notice.

11

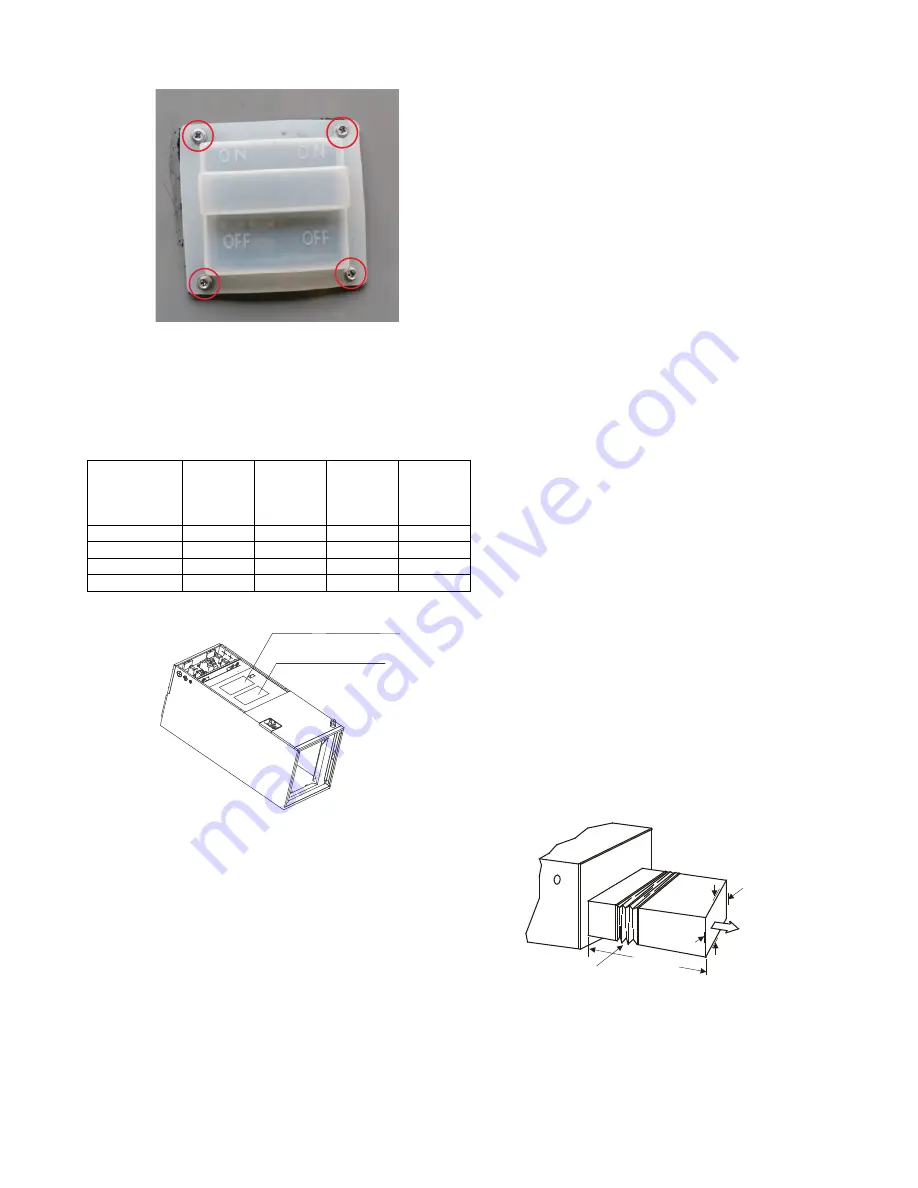

14. Fasten the resilient cap and seal on the upper cover plate with 4

screws.

Fig. 34 — Fasten the resilient cap

15. Reassemble the electronic control cover and secure it with screws.

Reassemble the upper cover plate and secure it with screws. After

the electric heating wiring is connected, confirm the plate is secure

before powering the unit on. Check all the wiring and ensure a

reliable connection with the wire body.

Table 6 — Specifications

Fig. 35 — Indoor Unit Wiring Diagram

NOTE:

The electric auxiliary heat wiring diagram is supplied with the

accessories. Please paste the wiring diagram in the designated position

after installing the heat modules.

Step 4 - Installing Ductwork

Connect the supply-air duct over the outside of the 3/4in (19 mm)

flanges provided on the supply-air opening. Secure the duct to the

flange, using proper fasteners for the type of duct used, and seal duct-

to-unit joint. If the return-air flanges are required, install the factory-

authorized accessory kit.

Use flexible connectors between the ductwork and unit to prevent

transmission of vibration. When the electric heater is installed, use

heat-resistant material for the flexible connector between the

ductwork and the unit at the discharge connection. Ductwork passing

through the unconditioned space must be insulated and covered with a

vapor barrier.

Units equipped with 20kW electric heaters require a 1in (25mm)

clearance to combustible materials for the first 36in (914mm) of

supply duct.

DUCTWORK ACOUSTICAL TREATMENT

Metal duct systems that do not have a 90 degree elbow and 10ft (3m) of

main duct to first branch takeoff may require internal acoustical insulation

lining. As an alternative, fibrous ductwork may be used if constructed and

installed in accordance with the latest edition of the SMACNA

construction standard on fibrous glass ducts. Both acoustical lining and

fibrous ductwork shall comply with the National Fire Protection

Association as tested by UL Standard 181 for Class 1 air ducts.

The air supply and return may be handled in one of several ways;

whichever situation is best suited for the installation (See Fig. 5 — on

page 5). A large number of issues encountered with split-system

installations can be linked to improperly designed or installed duct

systems. It is therefore very important that the duct system be properly

designed and installed.

Use of flexible duct collars is recommended to minimize the transmission

of vibration/noise into the conditioned space. Where the return air duct is

short, or where sound is liable to be a problem, sound absorbing glass fiber

should be used inside the duct.

Insulation of duct work must be installed according to local codes and

best practices. The supply air duct should be properly sized by use of a

transition to match unit opening.

This unit is not designed for non-ducted (freeblow) applications. Duct

work should be fabricated and installed in accordance with local and/

or national codes.

Fig. 36 — Flexible Duct Collar Connection

Specifications

No. of

Circuit

Breakers

No. of

Relays

No. of

Power

Cord

Groups

No. of

Power

Cord

Grounding

Screws

5kW

1

1

1

1

10kW

1

2

1

1

15kW

2

3

2

2

20kW

2

4

2

2

Indoor unit wiring diagram

Electric auxiliary

heat wiring diagram

Plenum Clearances

MINIMUM CLEARANCE

OF 1ft (25.4mm) ALL SIDES

RECOMMENDED FLEXIBLE

DUCT COLLAR

3.2ft (1m)