3: Operating Procedures

U3000/U4000 User Manual

19

(Issue 2.0)

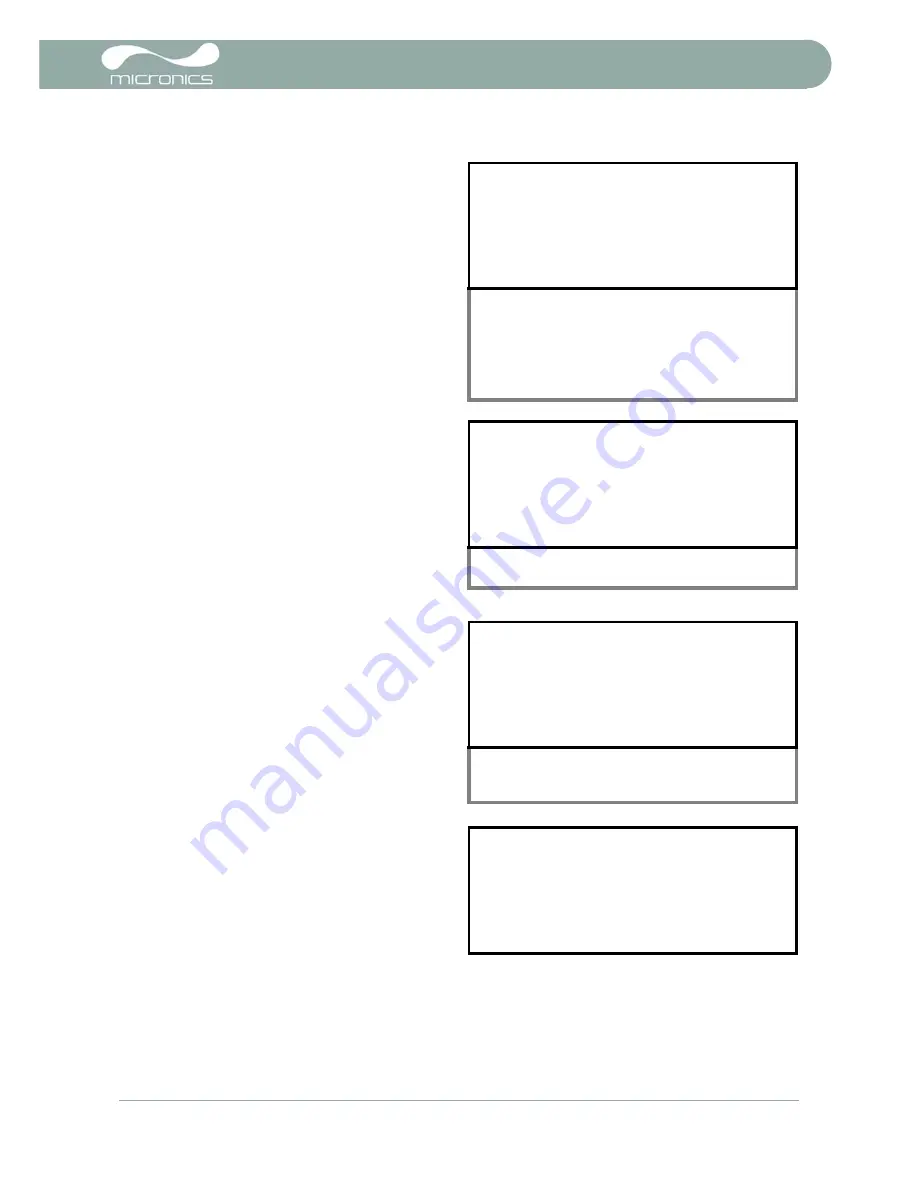

7.

Select the pipe wall material from the list

provided, then press

ENTER

.

If the material is not listed select

Other

and enter the propagation rate of the pipe

wall material in metres/sec. Contact

Micronics if this is not known.

8.

If a lining thickness value was entered

earlier, this screen is displayed to request

that you enter the lining material type. If no

lining thickness was entered this screen will

be bypassed.

9.

Select the lining material from the list

provided then press

ENTER

.

If the material is not listed select

Other

and enter the propagation rate of the lining

material in metres/sec. Contact Micronics if

this is not known

10. Select the fluid type from the list provided

and press

ENTER

.

If the liquid is not listed select

Other

and

enter a propagation rate in metres/

second.Contact Micronics if this is not

known

11. If you need to alter the fluid temperature

from that shown select either

°C

or

°F

with

the cursor and press the

ENTER

key.

12. Enter the new temperature value and press

the

ENTER

key.

13. The new temperature should now be

indicated in both °C and °F.

14. Select

Continue..

and press

ENTER

.

PIPE WALL MATERIAL

DD-MM-YY HH:MM:SS

Select pipe wall material

Mild Steel

S' less Steel 316

S' less Steel 303

Plastic

Cast Iron

Ductile Iron

Copper

Brass

Concrete

Glass

Other (m/s)

PIPE LINING MATERIAL

DD-MM-YY HH:MM:SS

Select pipe lining material

Steel

Rubber

Glass

Epoxy

Concrete

Other (m/s)

FLUID TYPE

DD-MM-YY HH:MM:SS

Select fluid type

Water

Glycol/water 50%

Glycol/water 30%

Lubricating oil

Diesel

Freon

Other (m/s) ––

FLUID TEMPERATURE

DD-MM-YY HH:MM:SS

Enter Fluid Temperature

°C: 25.00

°F: 77.00

Continue..