CorelLASER Installation

Please follow the software download

sheet included elsewhere in this manual.

After the software is downloaded to your computer,

you’ll need to reset or confirm certain settings of

CorelLASER so that the computer can communicate

with and control the LaserKnife 2525. Proceed as

follows:

Insert the USB “key” into a USB port on your computer.

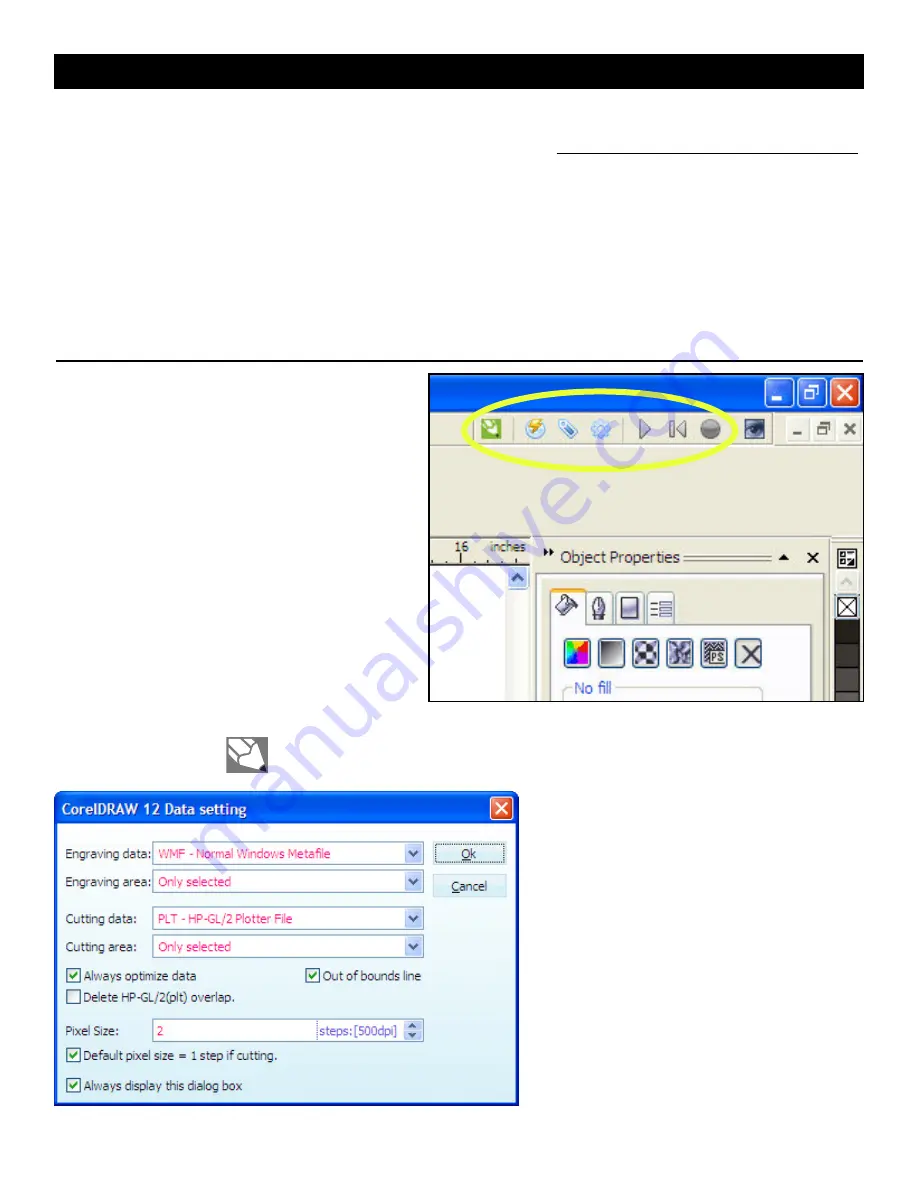

Start CorelLASER (give it time to load) and you

should ultimately see the CorelLASER controls in the

upper right corner of the Corel window…just below

the blue bar. This means CorelDRAW is open and

functioning and the CorelLASER plug-in is operating.

The LaserKnife 2525 is controlled by a plug-in program for CorelDRAW called CorelLASER, which is included with the

purchase of the machine and downloaded from the Micro-Mark web site at

http://www.micromark.com/downloads.dlp.

It has been designed to work with CorelDRAW versions 11 and later, including X3, X4, X5, X6, etc. (Version X3 is version

13, X4 is 14, and so on) running on Windows 2000 and later operating systems.

Please note: CorelLASER software is not compatible with Home & Student versions of CorelDRAW.

CorelDRAW must be loaded onto the computer before CorelLASER can be downloaded. The user needs to supply the

CorelDRAW program. It is available for download from the Internet. To prevent unauthorized use of CorelLASER, a USB “key”

is provided with the LaserKnife 2525. After the software is in place, be sure to plug the key into a USB port on your computer

or CorelLASER will not be accessible. A warning message or window will pop up in case you forget. Don’t lose the “key!”

LaserKnife 2525 Software Set Up

Click on the green pencil

(the bubble should say CorelDRAW setting) and a window will open that looks like the

following:

For the initial use of the LaserKnife 2525, we

suggest you use the pull-down menus to choose

settings that match those at left. Later, you can

change the settings based on the type of files

you are using, and whether or not you want the

machine to engrave/cut everything on the page

or only what you have selected.

You can later experiment with the effects of

changing the various settings… a rather fun

exercise!

Click OK to accept and save.

6