8

4.5

Removing the valve from the pipeline

Make sure that the valve is not pressurized and that

the pipeline is empty. Make sure that the medium

cannot flow into the section where servicing is to

take place.

Support the valve carefully with a hoist. Place ropes

carefully and unscrew the pipe flange bolts. See that

the ropes are positioned correctly, see Fig. 6. Lift

valve down.

4.6

Dismantling the valve

Place the valve in a standing position on the pipe

flange end. Use a level surface that will not scratch the

flanges. See that the body stud nuts (16) are facing

upward.

Mark the the body halves for correct orientation during

re-assembly.

Turn the ball to the closed position.

Remove the key (10).

Unscrew the gland nuts (18). Remove the disc spring

sets (150), the gland (9A), retainer ring (42) and

sleeve (9B)..

Unscrew the body stud nuts (16).

Remove the body cap (2). If the seat (7) is not lying on

the ball (3), prevent the seat from falling from the body

cap and detach it later.

Don’t leave your fingers

between the body cap and the surface!

Stand the removed body cap on its pipe flange.

Remove the seat (7) from body cap (2) if it is still in

place.

Unscrew the bonnet stud nuts (17). Remove the

shaft (5) and bonnet (8). Knock the bonnet off with a

piece of wood and a hammer, if needed.

Lift the ball (3) along with the trunnion plates (89)

and bearings (91, 99) out of the body (1) Handle the

ball carefully and place it on a soft surface.

Remove the seat (7) from the body (1).

Remove the trunnion plates (89) from the hubs of the

ball.

Remove the trunnion bearings (99) and the thrust

bearing (91) from each trunnion.

Push the shaft out of the bonnet.

Remove thrust bearings (70) from the shaft and

packing rings (69) from the bonnet (8).

Remove the body gasket (65) and the bonnet gasket

(66).

4.7

Inspection of removed parts

Clean removed parts.

See if the shaft (5) or bearings (70, 99) are damaged.

See if the ball (3) or seats (7) are damaged (scratched),

by examining them under bright light. The ball and the

seat can be replaced if necessary.

See if the body joint sealing surfaces are damaged.

4.8

Replacing parts

We recommend that soft material parts be replaced when-

ever the valve is dismantled for servicing. Other parts may

be replaced if necessary. Always use genuine spare parts to

ensure proper functioning of the valve (see section “Order-

ing spare parts”).

4.9

Assembly

Place the valve body (1) and the body cap (2) on the

pipe flange end. Use a level surface that will not scratch

the flanges.

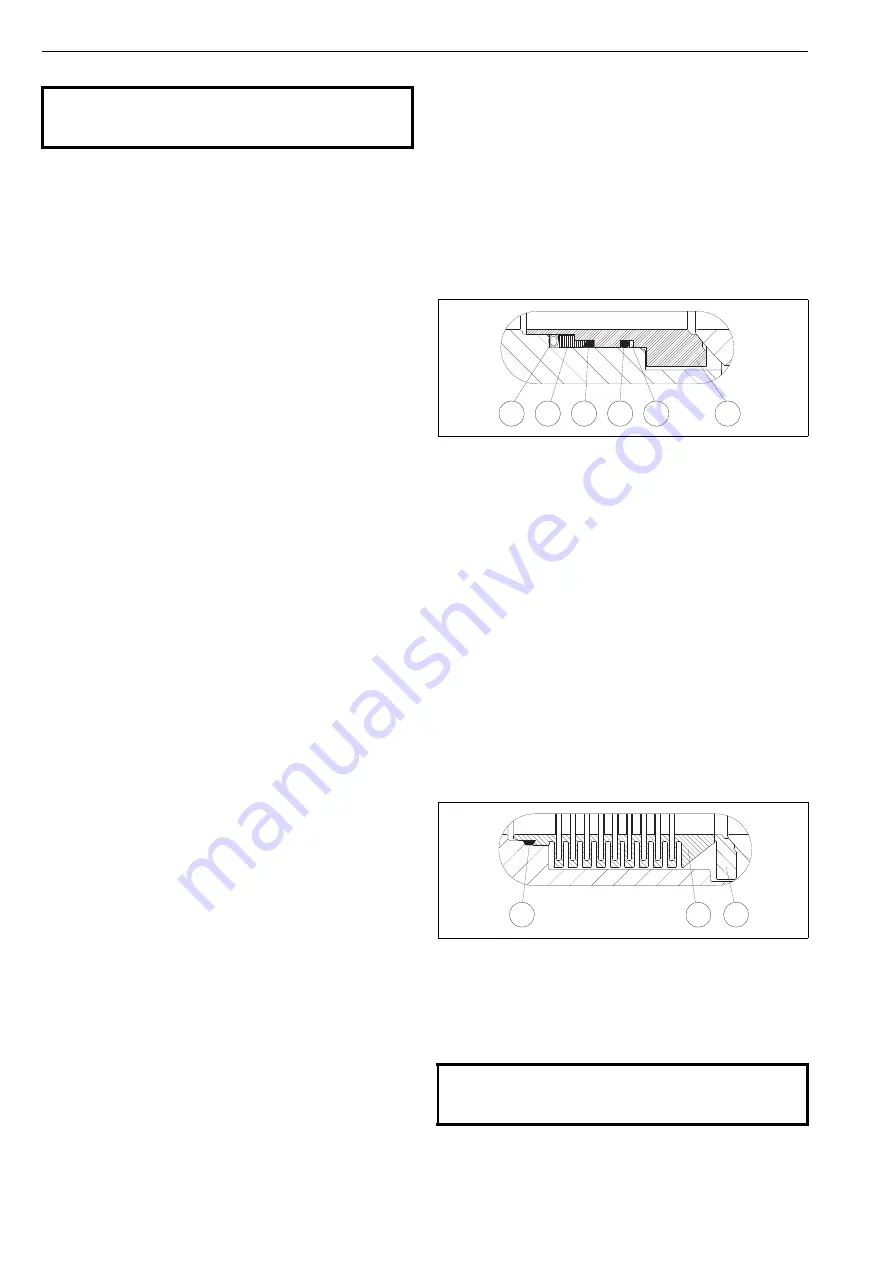

R seat:

Check the sealing surfaces.

Place the back seal (O-ring) (63) into the groove in the

seat. See Figure 12.

Place the back-up rings (64) made of PTFE strips at the

side of the O-ring. To ensure that the seam becomes

flexible, the strip must have slanted ends.

For easier assembly, lubricate the O-ring and back-up

ring surfaces facing the seats with silicone grease or

another suitable substance. Please ensure the compati-

bility with the flow medium. Place the backseal (130)

and ring (129) on the seat.

Place the spring (62) on the seat (7). Connect the

ends of the spring.

Place the seats into the body and body cap by hand

or if necessary, using a plastic mallet. The seat is in

correct position when the spring touches the body

shoulder.

F seats:

Check the sealing surfaces.

Place the back seal (63) into the bellows (62). See Fig-

ure 13.

Place the bellows and seat (7) into the body counter-

bore.

CAUTION:

Do not dismantle the valve or remove pipeline while the

valve is pressurized!

Fig. 12

S seat

Fig. 13

F seat

CAUTION:

Be careful not to damage the lapped surfaces of the bel-

lows and the seat.

129 130

7

63

64

62

63

62

7

Summary of Contents for NELES XH Series

Page 15: ...15 ...