4 KH 70 en

5

The incorrect position or installation of the flanges

can cause deformations on the valve’s body and this

could lead to operating problems.

It is very important to make sure that the valve is cor-

rectly aligned and parallel to the flanges to prevent

leakages and avoid deformations. Ensure the valve is

assembled in open position.

The screws in the tapped blind holes will have a

maximum depth (Fig. 2) and will never reach the

bottom of the hole. The following table (Table 1)

shows the maximum thread depth in the holes and

the maximum torque to be applied to the flange

screws:

Fig. 2

Tabla 1

The equipment must be firmly installed in the pipe.

It will be joined to the pipe with a screw joint.

The screws and nuts to be fitted must also be suita-

ble for the operating conditions and their measure-

ments must in accordance with the approved plans.

The screws and nuts must be fitted diametrically.

To torque to apply to the fastening screws and nuts

must be correct according to the applicable stand-

ard, we recommend the initial assembly be carried

out with a low tightening torque and after all the

screws are in place, the final torque is applied.

As regards scaffolding, ladders and other auxiliary

elements to be used during the assembly, follow the

safety recommendations indicated in this dossier.

Once the equipment has been assembled make sure

that there are no elements, whether interior or exte-

rior, which can interfere with the gate valve’s move-

ment.

Make the relevant connections (electrical, pneu-

matic, hydraulic) in the equipment’s drive system fol-

lowing the instructions and wiring diagrams

supplied it.

The operation of the equipment must be coordi-

nated with the site’s control and safety staff and no

modifications are permitted in the equipment’s

external indication elements (limit switches, posi-

tioners, etc.).

When operating the equipment follow the safety

recommendations indicated in this dossier.

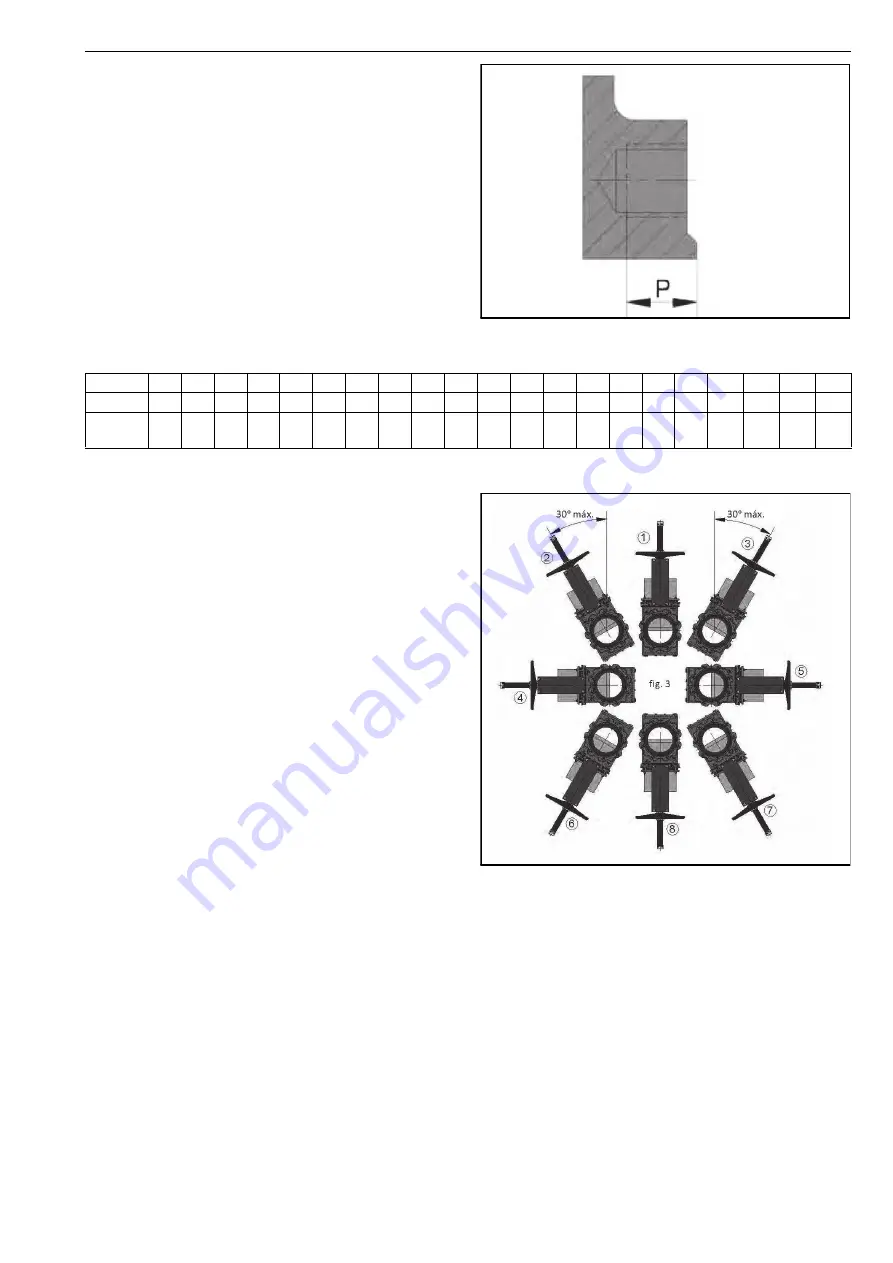

3.5

Assembly position

(Horizontal Pipe)

In horizontal pipes it is recommended that the knife gate

valves be assembled in vertical position, although other

assembly positions are also possible.

Fig. 3

Position 1:

This is the most advisable position.

Position 8:

The valve can be installed in this position but

you are advised to contact the supplier if this is necessary.

Positions 2, 3, 6 and 7:

For large valves (more than DN300),

the maximum angle with the installation vertical is 30º. For

smaller sizes the angle can be increased up to 90º (positions

4 and 5).

When it is necessary to install large valves in any of these

positions, it is recommended to consult the supplier, as in

these cases, due to the weight of the actuator, a suitable

support must be made to prevent deformations and

operating problems in the valves.

Positions 4 and 5:

For smaller sized valves, the valves can

be installed in these positions. To install larger valves (more

than DN300) in any of these positions, please contact the

supplier. In these cases, due to the weight of the actuator, a

suitable support must be made to prevent deformations

and operating problems in the valves.

DN

50

65

80

100 125 150 200 250 300 350 400 450 500 600 700 800 900 1000 1200 1300 1400

P

14

14

14

14

15

15

17

17

20

21

23

24

25

26

26

26

26

27

29

29

30

TORQUE

(Nm)

45

45

45

45

45

88

88

88

88

88

152 152 152 223 223 303 303

412

529

529

685