15

OPERATION MANUAL

4. OPERATION

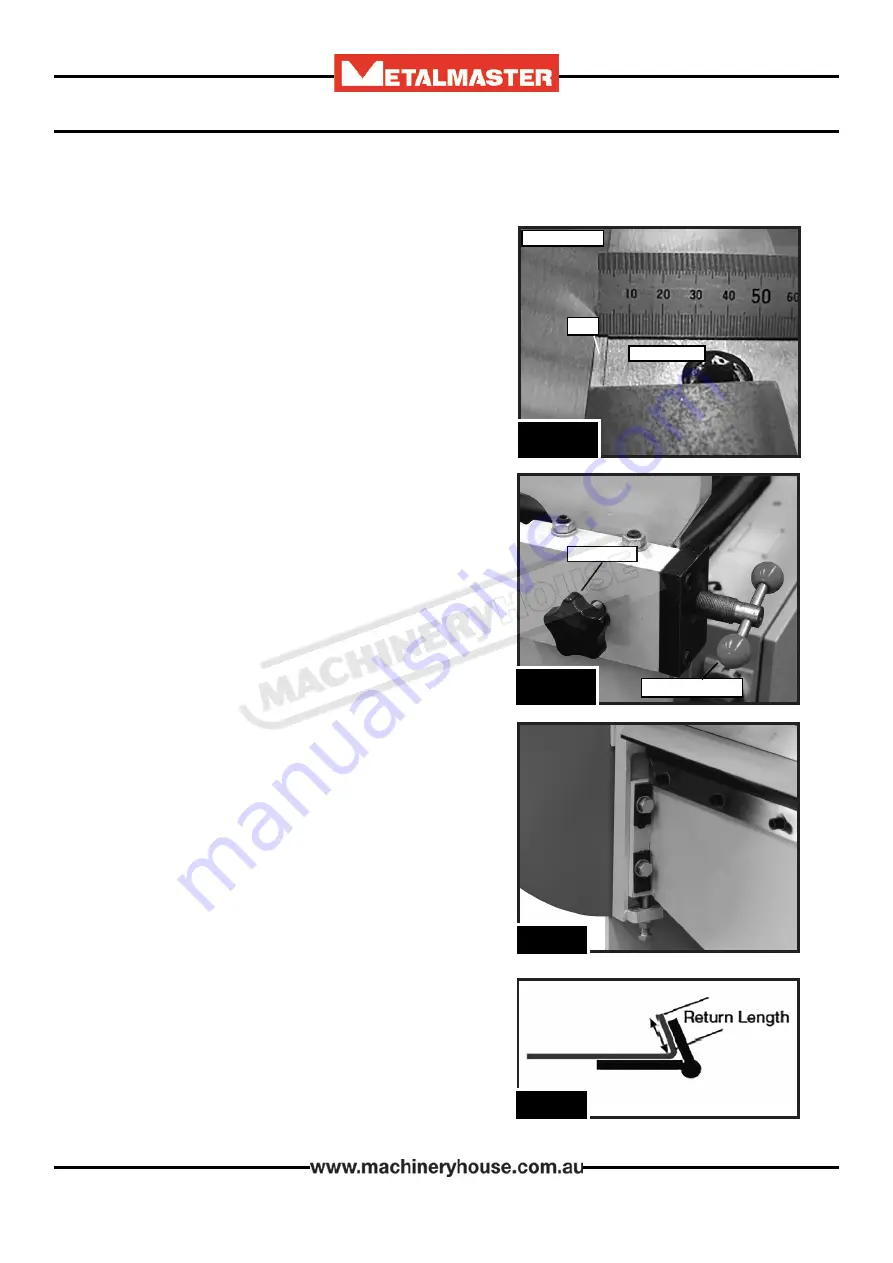

4.1 SETTING THE CLAMP GAP

Before operating the machine the clamp gap needs

be set to match the material thickness

The Clamp gap must be set to a minimum of 1.5 x

material thickness. (Fig. 4.1)

Example: If the material that is to be bent is 2mm

then the clamp gap must be set to a minimum of

3mm.

Each panbrake may have different mechanisms for

adjusting the clamp gap but the formula of 1.5 x

Material Thickness must be maintained to prevent

overload and possible damage.

These machines are fitted with an easy to use clamp

beam adjustment. There are two adjustment screws

(Fig.4.2) on the machine situated on each side of

the machine.

To adjust

1. Loosen the lock screws on both sides

2. Turn the two adjusting screws until the gap

(Fig.4.2) is correct.

3. Tighten the two lock screws and recheck the gap

If needed, a combination of top clamp adjustment

and apron adjustment can be applied.

NOTE:

The locking bolts on the apron must be re-

leased before adjusting, then tightened when the

correct height is reached.

RETURN LENGTH - LIMITATION

Caution

- There is a minimum “Return Length” of 15

x Thickness of Material when bending thicker mate-

rial over 1mm. Damage could occur to the machine

if the return is too short.

Example: If bending 2mm the minimum return

length must be 30mm (Fig. 4.4)

F

ig

. 4.1

C

lamp

Finger

F

olding

arm

g

ap

F

ig

. 4.2

l

oCk

sCrew

a

djusting

sCrew

F

ig

. 4.3

F

ig

. 4.4

22/07/2019

Instructions Manual for PB-422L (S576)

15