QC11Y Hydraulic Guillotine Shear

7

4.2

Installation of the machine

4.2.1 When installation , remove the balling cover on the worktable , and put the

same height pad at the processing side. And put the IM ruler on the pad. And then

use the lever meter to adjust vertically and horizontally , the allowance is less than

0.2mm every 1000mm length, the left and right direction should be same. The base

depth for machine installation depends on the earth situation (but not less than

500mm.) The earth pouring work is done by twice( pls see the chart). After 15 days

from the date of first pouring, put the machine on the base and adjust horizontally

and then set the foot screws and adjust the pad iron and then make the second

pouring. After 48 hours of that, adjust horizontally and tighten the foot screws.

4.2.2 Before the machine delivery, put the knife beam to bottom dead point and

fix up with pad to prohibit accidents;

after installation, pls backout the

twice fixed pads at the inner-bottom between left and right

boards, or else it will cause mechanism troubles.

Summary of Contents for HG3208VR

Page 1: ...19 3 08 HG3208VR HYDRAULIC GUILLOTINE MANUAL S960...

Page 2: ...QC11Y 8X3200 Hydraulic Guillotine shears Operation Manual Serial No Q709103...

Page 3: ...QC11Y Hydraulic Guillotine Shear 1 Contents...

Page 4: ...QC11Y Hydraulic Guillotine Shear 2...

Page 6: ...QC11Y Hydraulic Guillotine Shear 4...

Page 8: ...QC11Y Hydraulic Guillotine Shear 6 4 Hoisting and Installation...

Page 13: ...QC11Y Hydraulic Guillotine Shear 11 overflow valve 5...

Page 14: ...QC11Y Hydraulic Guillotine Shear 12...

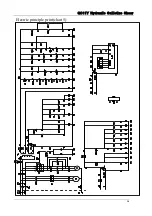

Page 16: ...QC11Y Hydraulic Guillotine Shear 14 Electric principle print chart 5...