- 16

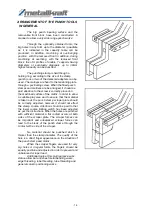

ARRANGEMENT OF THE PUNCH TOOLS

IN GENERAL

The big punch bearing surface and the

removable front block have been constructed in

manner to allow a very wide range punch works:

Through the optionally obtained tools, the

big holes in any form up to the diameter / quadrate

as it is indicated in the capacity table can be

produced. In addition, machining at overhanging

position, with the removed front in addition, during

machining at overhang, with the removed front

block, the of U profiles of double T supports having

diameters or eventually diagonals up to 38mm

highest capacity can be punched.

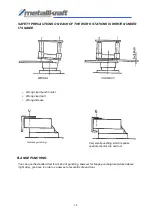

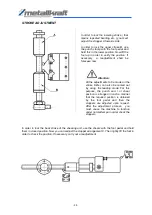

The punching stamp is held though a

holding ring, according to the size of the stamp

(punch) one or two of the delivered adapters can be

used. The matrixes are fixed to the tensioning plate

through a positioning screw. When the filled punch

stamps and matrixes are be arranged, it should be

paid attention to the screw is correctly placed on

the machined surface of the matrix. In order to allow

a suitable play area and to ensure that the material

is taken out, the punch stamp scraper plate should

be correctly adjusted, however it should not effect

the stamp course. Attention should be paid to that

the lower course limiting switch has been adjusted

as per the instructions. When the holes are punched

with sufficient material, a flat contact occurs at both

sides of the scraper plate. The scraper forces can

be important and unbalanced scraper forces can

lead to the break of the punch stamp through the

contact with a side of the scraper.

No material should be punched which is

thicker than the stamp diameter. The quality of the

hole is a direct finger appearance on the situation of

the punch stamp and matrix.

When the scraper fingers are used for very

big holes or irregular forms, the fingers should be

equally position and adjusted in order to prevent and

unbalanced scraper load.

Additional tools at this multi purpose work

station allow bar and sheet metal bending works,

edge threading, tube threading, tube threading and

general column positioning works.