- 10

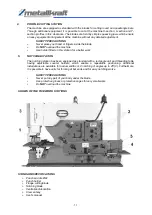

FIVE WORK STATIONS

1.

1-PUNCHING STATION

All punching operating are processed by means of hydraulic power thus giving the machine

the ability to punch very efficiently and silently. It can either be used to punch thick materials

or thin materials in layers together. Punching is silent, powerful and efficient. The waste

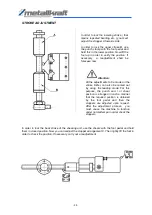

materials in layers together. The punching table consists two parts. First is the punching

flange. The second is holder. The holder is a device that holds the material after punching not

to come back with the punch. It must be equally adjusted or it can break the punch. There are

different holders for different materials. However the standard holder which we supply is

suitable for punching is between 6-38 mm.

SAFETY PRECAUTIONS

All power and depth and other adjustment must be done under full control of an

experienced technician

Please check all the moving parts before working

Check the punch and die that they are in the same direction

Adjust the holder equally and according to the material

always use the protective plastics

on small and accuracy needing works use special protection

while replacing the punch or die or holder shut the main switch

never leave the machine unattended

do NOT overload the machine

2.

SHEARING STATION

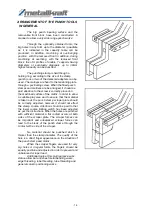

The shearing unit has been equipped with a simple and robust fixing installation, which can be

adjusted for any material thickness within the cutting the cutting capacity of the machine. A

shearing up to 45

0

for flat bars or the cutting of the flanges of angle profiles, which have

previously been cut at inclined-angle cutting stations.

The shearing blades constructed for mass production can be used on both sides ( the upper

blade has 2 cutting edges, the lower blade has 4 cutting edges ) and ensure a clean cutting

with the minimum deformation, from the full capacity till a material thickness of only 2 mm.

SAFETY PRECAUTIONS

Always use the bolder

Never place any part of your body under the blade

Do NOT overload the machine

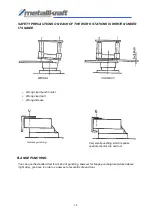

3.

CUTTING STATION

This station enables the cutting of big angles with a capacity of up to 90

0

and smaller angles

up to 45

0

.

The angle between 45

0

and 90

0

will be obtained, these will be cut first at 90

0

and then

at the shearing station of the flange will be cut at the required angle. The fixing installation

supports the material in a manner to provide a correct cutting.

SAFETY PRECAUTIONS

Never place your hand or fingers inside the blade.

Do NOT overload the machine

Use holder fitted on this station for a better work