LOCATION

The pump should ideally be placed as close as

possible to the liquid supply source. Allow sufficient

space on the sides and overhead to permit inspec-

tion and maintenance work to be performed.

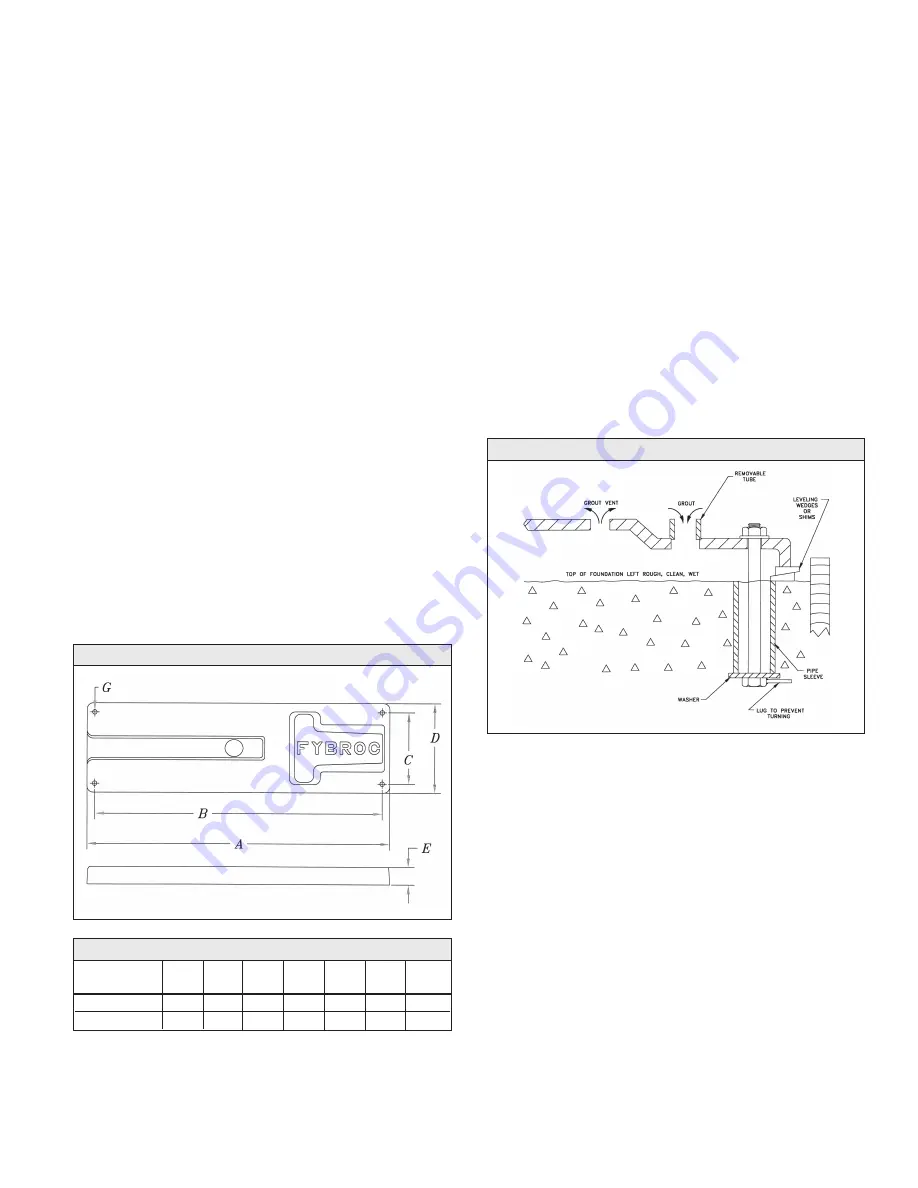

FOUNDATION

The foundation for the pump should be level, pro-

vide rigid support and alignment of pump and

motor. It should also be of sufficient mass to

dampen any vibrations developed. Typically this is

accomplished by installing and grouting a Fybroc

baseplate on a concrete foundation.

Foundation bolts of the proper size should be

imbedded in the concrete with anti-rotation lugs, lo-

cated by a drawing or template. (See Figure 1 and

Table 1 below for bolt-size and locations). A pipe

sleeve larger than the bolt should be used to allow

enough lateral movement for final positioning of the

bolts. (See Figure 2 below). Leveling wedges or

shims should be placed under the sides of the

baseplate to level the unit and the foundation bolts

slightly tightened.

A wood form can now be built around the edge of

the baseplate to contain the grout. The top of the

rough concrete foundation should be wetted down

prior to grouting. A good grade of non-shrinking

grout can now be poured through the fill hole on

the top of the fiberglass baseplate. On baseplates

with raised motor mounting sections, a short length

of pipe or tubing can be fitted into the grout hole to

allow the grout to completely fill the raised section

to the baseplate up to the vent hole in the raised

section, as shown in figure below. Once the grout

starts to set, the extension can be removed, leav-

ing the grout level with the top of the baseplate.

Once the grout has fully hardened, usually about

48 hours after pouring, the foundation bolts can be

fully tightened.

INITIAL ALIGNMENT

Final alignment of the pump and driver through the

flexible coupling is of extreme i mportance for

trouble free mechanical operation. If the driver was

mounted at the factory, the unit was rough aligned

with plastic shims prior to shipment. These shims

are not to be considered permanent and should be

replaced with metal shims during final alignment.

In addition, during transit and subsequent handling

any factory alignment may be disturbed. All units

must be re-aligned after installation and/or mainte-

nance.

The following steps are suggested to establish the

initial alignment of the pump unit:

1) Be sure the foundation bolts are tight.

2) Be sure the casing and frame feet are tight.

3) Use metal shims under the driver feet to

establish parallel and angular alignment of

pump and motor shafts.

FIGURE 2

INSTALLATION HORIZONTAL PUMPS

FIGURE 1

TABLE 1

Base A B C D E G Bolt

Plate Size

SP-1 50 47 1/2 12 15 2 7/8 3/4 1/2

SP-2 65 62 1/2 17 20 4 1 3/4

NOTE: Dimensions A & B are maximums and may be

less depending on pump/motor size.

4