Page 8

3.7 Configuration of Zero and Span Procedures

The ZERO and SPAN Buttons are under the transmitter’s

nameplate. The ZERO, SPAN, ZERO TRIM, ZERO ADJ, Units,

Range, Dampening, LCD and decimal set functions are configurable

using the ZERO / SPAN buttons.

Zero/Span Configuration Process

Remove both name plate screws on the upper part of transmitter.

Remove top name plate to access the Zero and Span Buttons.

(following Figure 3-4)

1. Zero Configurations

Set the current process value for Lower Range Value (4 mA).

Apply zero pressure for 10 seconds and push the Zero Button

for 5 seconds. The LCD should display “Zero”. Push the Zero

button for 3 seconds, after 1 second the LCD should display

“-ZE-”. This message means the zero configuration is

finished. If the zero configuration failed, the LCD will display

“SPEr” or “SEtE”, try repeating the zero configuration steps.

2. Span Configurations

Apply the desired pressure for 10 seconds and push the Span

Button for 5 seconds. The LCD should display “Span”. Push

the Span button for 3 seconds, after 1 second the LCD should

display “-SP-”. This message means that the span

configuration is finished. If the span configuration failed the

LCD will display “SPEr” or “SEtE”, try repeating the span

configuration steps.

• Please refer to Appendix 1 for the button error and LCD display

message.

The other functions supported by the ZERO / SPAN Buttons are

below.

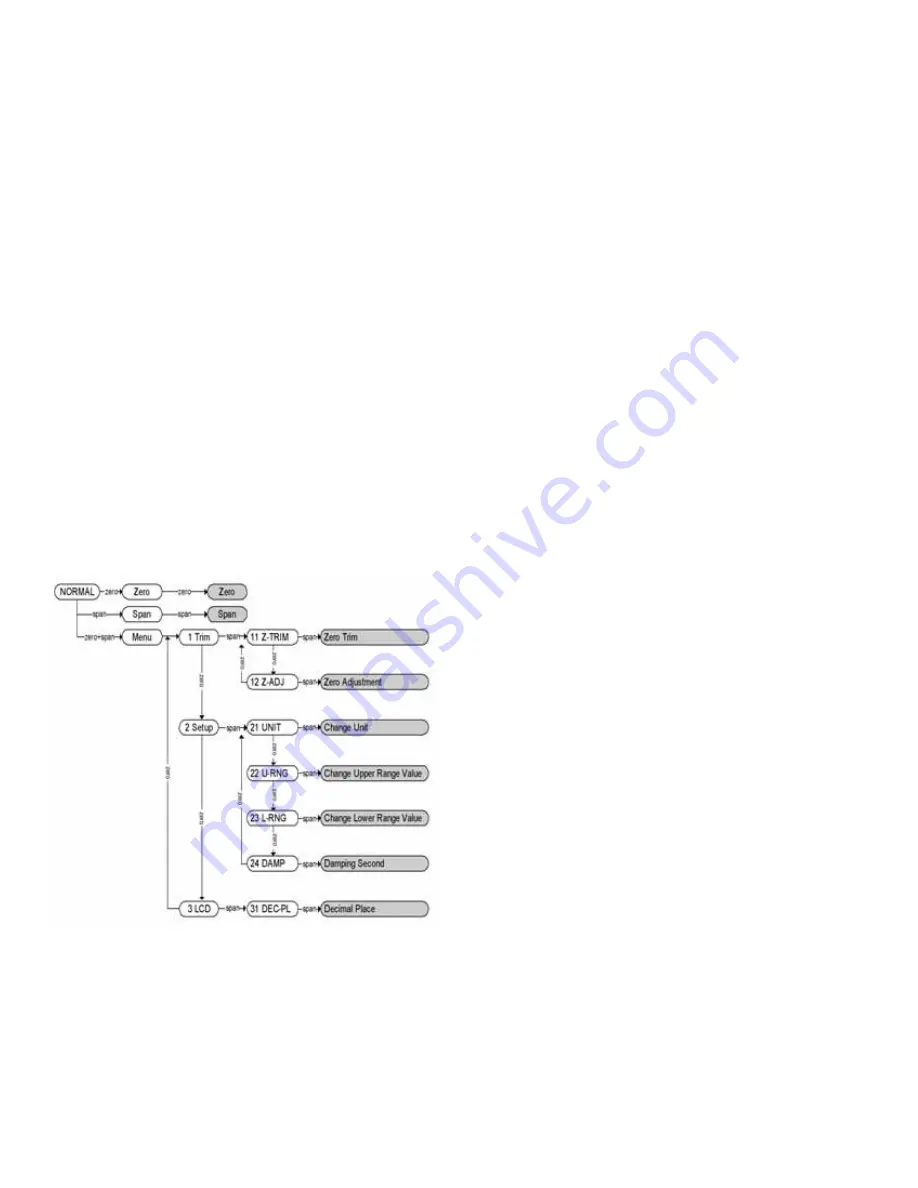

[Menu Tree for Zero+Span Button Function]

1. Moving between menus: Zero

2. Enter or moving to sub menu: Span

3. Moving to top menu: Zero+Span

•

Press the button for 3 seconds to execute each function. After

3 seconds press the Zero+Span buttons, the LCD display

will change from Menu to Trim. To see the next menu, press

the Zero button for 3 seconds. Use the Zero button to move

down the directory.

•

Use the Span button to select the displayed menu. The same

procedure will be used for the sub menus.

Caution: 30 seconds without any action, the button function will

return to normal operation.

4. How to select a numerical value

A Functions use numerical values: 12 Zero Adjustment, 22

Change Upper Range Value, 23 Change Lower Range Value,

24 Dampening Second

B How to select numerical value: First, select an increasing rate

(10

n

), then change each decimal value to increase or

decrease as wanted. For example, select 3810 : Select

increasing rate 1000 -> Increase 3 times -> Select

increasing rate 100 -> Increase 8 times -> Select

increasing rate as 10 -> Increase 1 time

C To select the increase / decrease steps: SelInc message will

be displayed on the bottom of the LCD. Select parameter and

press the Zero button : The decimal value will be changed

when the Zero button is pressed. After set, press the span

button to execute the parameter.

D To set the required values using Zero/Span buttons: VALUE

message will be displayed on the bottom of the LCD.

1. Press the Zero button, the menu will increase 1 item.

2. Press the Span button, the menu will decrease 1 item.

3. After setting, save the parameter by pressing the

Zero+Span buttons.

E To set the final value, repeat C and D.

F

After setting the final parameter, exit the menu by pressing the

Zero+Span buttons.

5. Exercises for each function

•

ZERO TRIM

1. Access the menu by pressing the Zero+Span buttons.

2. Move to the sub directory using the Span button until the

1 TRIM message appears on the display.

3. Change the Zero Trim Function by using the Span button

until the 11 Z-TRIM message appears on the display.

•

ZERO ADJUSTMENT : Change the PV value to 14

1. Exit the menu by pressing the Zero+Span button.

2. Moving thru the sub directory using the Span button

until 1 TRIM message appears.

3. Moving thru the sub directory using the Zero button

until 11 Z-TRIM message appears.

4. Access the Zero Adjustment function by pressing the

Span button until the 12 Z-ADJ messages appears.

5. When the SelInc message appears, press the Zero button

repetitively until the 10.0 message appears on the LCD.

Set the value by pressing the Span button.

6. When VALUE message appears, change the LCD value

to 10.0 and press the Zero button, then press the

Zero+Span buttons.

7. When Sellnc message appears, change the LCD value to

1.0 and press the Zero button, then set the value and

press the Span button. Press the Zero+Span buttons after

the LCD value changes to 14.0.

8. To save the settings, press the Zero+Span buttons until

the SelInc message appears.

•

CHANGE UNITS

1. Access the menu by pressing the Zero+Span buttons.

2. Moving to next menu by pressing the Zero button until the

1 TRIM message appears.

3. Moving thru the sub directory press the Span button until

the 2 SETUP message appears.

4. Press the Span button to access 21 UNIT, press Span

again to access Change Unit.

5. Save the values by pressing the Span button when the

desired value is displayed on the LCD.

P-3100:TEMPLATE 3/1/10 11:27 AM Page 9